+86-18367343973

- 1 The Triad of Aesthetic Assessment: A Systematic Framework

- 2 Quantifying Realism: Beyond the Naked Eye

- 3 Measuring Gloss Level: The Science of Surface Reflection

- 4 Analyzing Texture Depth: The Tactile Dimension

- 5 Practical Evaluation Protocol for B2B Specification

- 6 Frequently Asked Questions (FAQ)

- 6.1 1. How does the surface texture of a WPC panel impact its cleanability compared to a perfectly smooth panel?

- 6.2 2. Can the gloss level of a WPC panel change or degrade over time?

- 6.3 3. What is the technical process for achieving a perfectly synchronized texture and print?

- 6.4 4. For a large project with multiple batches, how can color and gloss consistency be guaranteed?

- 6.5 5. From a B2B perspective, what is the most important visual differentiator between a low-cost and a premium WPC wall panel?

The aesthetic performance of interior wpc wall panel is a critical factor in its commercial success and user satisfaction. Beyond the well-documented structural and moisture-resistant properties, the ability of these engineered products to authentically replicate the visual and tactile qualities of natural materials—wood, stone, or to present a flawless solid color—is paramount. For architects, interior designers, and B2B procurement managers, a systematic and objective framework for assessing design fidelity is essential. This article provides an engineer-level methodology for evaluating the three core aesthetic dimensions of interior wPC wall panel: realism, gloss level, and texture depth, empowering professionals to specify with confidence for projects ranging from residential wpc wall panel for living room features to large-scale commercial installations.

YXWPC1228 8MM Thickness WPC Wood Veneer Decoration Paint-Free Board Solid Wood Wall Board

The Triad of Aesthetic Assessment: A Systematic Framework

A comprehensive evaluation moves beyond subjective "look and feel" to quantifiable and repeatable metrics. The perception of quality is governed by the interplay of three distinct yet interconnected characteristics: the accuracy of the visual pattern (realism), the nature of its surface light reflection (gloss), and its three-dimensional topography (texture). A superior modern wpc wall design excels in all three areas simultaneously.

Quantifying Realism: Beyond the Naked Eye

Realism is the degree to which the printed or embossed pattern mimics its natural counterpart. Its assessment involves both macro and micro-level analysis.

Macro-Pattern Authenticity and Repeat Length

Natural materials like wood and stone are characterized by random, non-repeating patterns. A common failure point in lower-quality panels is a short and easily detectable pattern repeat, which creates a visually artificial "wallpaper effect." High-fidelity decorative wpc wall covering features a long, randomized pattern repeat, often exceeding 10 feet or more, making repetition virtually imperceptible in a standard installation. This requires sophisticated digital printing technology and extensive pattern libraries.

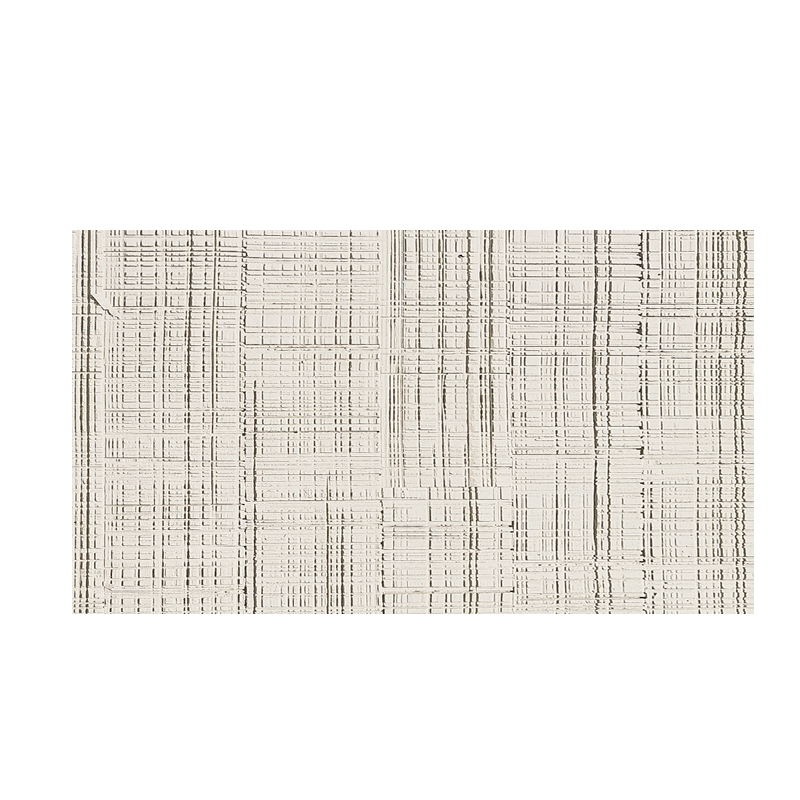

Micro-Detail and Color Variation

Authenticity lies in the microscopic details. This includes the replication of wood's medullary rays, the subtle color variation within a single stone slab, and the presence of natural "imperfections" like knots and mineral veining. High-resolution scanning and printing are used to capture these details. A key indicator is the use of multiple print stations to layer different colors and effects, creating a deep, complex color field that avoids the flat, "pasted-on" appearance of low-quality prints. This level of detail is what distinguishes a premium wood grain wpc panel.

Comparative Analysis of Realism Factors

| Assessment Criterion | Low-Quality Panel | High-Quality Panel |

| Pattern Repeat Length | Short (< 5 feet), easily visible repetition | Long (> 10 feet), random and imperceptible |

| Color Depth & Variation | Flat, uniform color; limited tonal range | Multi-layered, complex color with natural highs and lows |

| Micro-Detail Fidelity | Blurred or missing fine details (e.g., wood pores, stone crystals) | Sharp replication of natural micro-features |

Measuring Gloss Level: The Science of Surface Reflection

Gloss, measured in Gloss Units (GU) with a gloss meter at a standard angle (e.g., 60°), is a precise quantification of how a surface reflects light. It is a primary driver of perceived quality and ambiance.

Gloss Uniformity and Sheen Consistency

In natural materials, gloss is rarely perfectly uniform. However, for manufactured panels, consistency across the entire surface and between different batches is critical. A high-quality interior wpc wall panel will exhibit a uniform gloss level with no cloudy patches or streaks. Inconsistency is a sign of poor manufacturing control in the coating or calendaring process. For wpc wall panel for living room applications, a consistent low-sheen matte finish is often preferred for its ability to hide imperfections and provide a soft, sophisticated look.

Gloss Ranges and Their Application

The choice of gloss level is both an aesthetic and functional decision. Higher gloss surfaces are more reflective and easier to clean but also highlight surface imperfections and seams. Lower gloss surfaces are better at concealing flaws and reducing eye strain.

| Gloss Classification (at 60°) | Gloss Unit (GU) Range | Visual Effect & Typical Application |

| Matte / Flat | 0 - 10 GU | Non-reflective, soft feel. Ideal for residential living rooms, ceilings. |

| Eggshell / Satin | 10 - 25 GU | Soft luster, easy to clean. Versatile for bedrooms, hallways, commercial spaces. |

| Semi-Gloss | 25 - 60 GU | Noticeable shine, highly durable. Suitable for kitchens, bathrooms, trim. |

| High-Gloss | > 60 GU | Mirror-like reflection, modern. Used for accent walls and high-end retail. |

Analyzing Texture Depth: The Tactile Dimension

Texture depth refers to the physical, three-dimensional topography of the panel surface. It is the feature that most directly bridges the gap between visual and tactile realism.

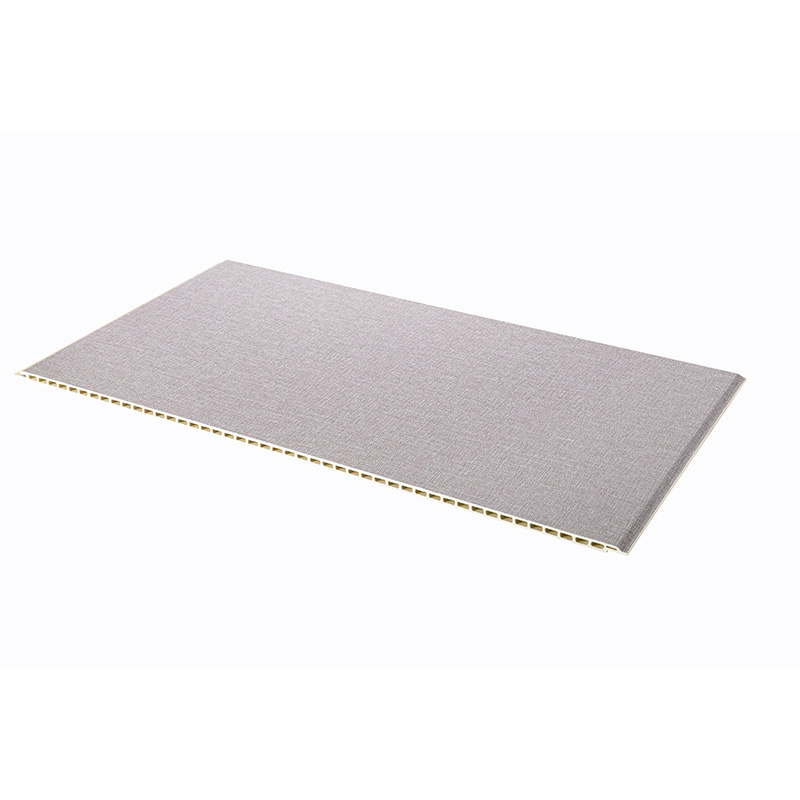

Synchronized Texture and Print (Register)

The highest mark of quality is achieved when the embossed texture is in perfect register with the printed pattern. For example, the raised grain of a wood grain wpc panel should align precisely with the darker grain lines in the print. Misalignment between texture and print is a clear indicator of a lower-tier manufacturing process and significantly degrades the perceived realism. This synchronization is a technical challenge that requires precision in both the embossing roller fabrication and the panel extrusion process.

Quantifying Depth and Tactile Response

While a profilometer can provide a quantitative depth measurement (Ra, Rz values), a practical qualitative assessment is often sufficient. The texture should feel authentic to the touch—a wood grain should have a varied, grain-like feel, not a simple, uniform stipple. The depth should be significant enough to cast subtle shadows under ambient light, enhancing the three-dimensional illusion, but not so deep that it becomes difficult to clean. This balanced, realistic texture is a hallmark of a sophisticated modern wpc wall design.

Texture Quality Comparison

| Texture Characteristic | Low-Quality Panel | High-Quality Panel |

| Register (Sync with Print) | Poor or no alignment; texture and pattern are unrelated | Excellent alignment; texture perfectly follows the printed design |

| Depth and Complexity | Shallow, simple, and uniform stipple pattern | Deep, varied, and complex topography mimicking natural material |

| Tactile Authenticity | Feels like plastic with a pattern | Feels convincingly like wood or stone |

Practical Evaluation Protocol for B2B Specification

For procurement and specification, a standardized evaluation process is recommended.

- Request Physical Samples: Always evaluate full-size, production samples, not small swatches. Observe the sample under different lighting conditions (daylight, warm, and cool artificial light) and from multiple angles.

- Perform the "Touch Test": Run your hand over the panel with your eyes closed. Does it feel like the natural material it is imitating? Then open your eyes to check for texture/print synchronization.

- Check for Pattern Repeat: If possible, request to see a depiction of a multi-panel installation to visually check for pattern repetition.

- Verify Technical Data: Require the supplier to provide gloss level specifications (GU values) and information on their pattern repeat length. A manufacturer with a strong R&D focus, like Haining Yunxi New Material Technology Co., Ltd., will have this data readily available and can provide a wide range of decorative wpc wall covering options with certified aesthetic properties.

- Assess the Complete System: Evaluate how the panels, accessories, and joint details work together to create a seamless aesthetic whole, which is crucial for a high-end wpc wall panel for hotel project.

Frequently Asked Questions (FAQ)

1. How does the surface texture of a WPC panel impact its cleanability compared to a perfectly smooth panel?

A deeply textured surface can potentially trap dust and grime more than a smooth surface. However, the non-porous nature of the PVC/WPC material means that any accumulated dirt sits on the surface and can be easily wiped away with a damp cloth. For high-hygiene environments, a panel with a medium texture and a semi-gloss finish often provides the best balance of realism and easy maintenance, a key consideration for wpc wall panel for hotel corridors and rooms.

2. Can the gloss level of a WPC panel change or degrade over time?

High-quality WPC panels with UV-stable top coats are designed to maintain their gloss level for the product's lifetime. Degradation, or "gloss loss," is typically caused by UV radiation and surface abrasion. Inferior products may use lower-quality coatings that can chalk or fade, leading to a reduction in gloss. Specifying panels from a manufacturer with a proven track record in material science ensures long-term aesthetic stability.

3. What is the technical process for achieving a perfectly synchronized texture and print?

This is achieved through a highly controlled co-extrusion or lamination process. A base substrate is first printed with the high-resolution pattern. This printed sheet is then fed through an embossing unit equipped with a custom-made steel roller that has the negative of the desired texture etched into it. Precision optical sensors are used to align the embossing roller with the printed pattern in real-time before heat and pressure are applied to impart the texture in perfect register.

4. For a large project with multiple batches, how can color and gloss consistency be guaranteed?

Consistency is managed through Statistical Process Control (SPC) in manufacturing. This involves:

- Using master batches for color to ensure pigment consistency.

- Controlling the extrusion and coating parameters (temperature, pressure, speed).

- Continuously monitoring gloss and color with spectrophotometers on the production line.

- Batch-to-batch quality control checks against a standard approved sample.

Always request production samples from the actual batch intended for your project.

The single most telling differentiator is the synchronization of texture and print. Low-cost panels often have a generic, unrelated texture applied to a printed surface, which the brain immediately registers as "fake." A premium panel, where the tactile grain aligns perfectly with the visual grain, creates a cohesive and convincing illusion of natural material that is difficult to achieve and commands a higher price in the market for a wood grain wpc panel.