Haining Yunxi New Material Technology Co., Ltd.

Haining Yunxi New Material Technology Co., Ltd. is

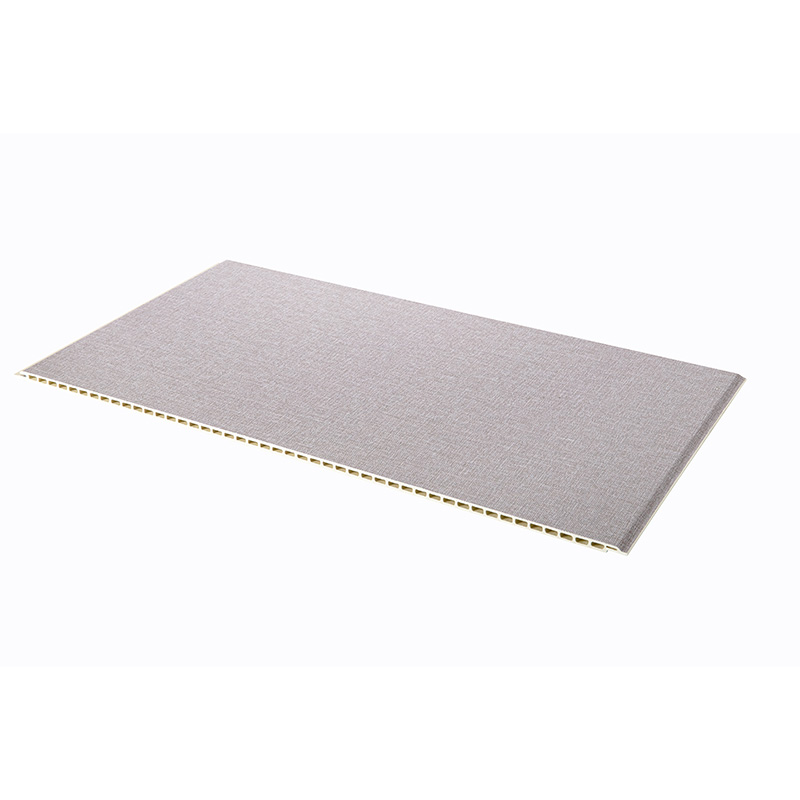

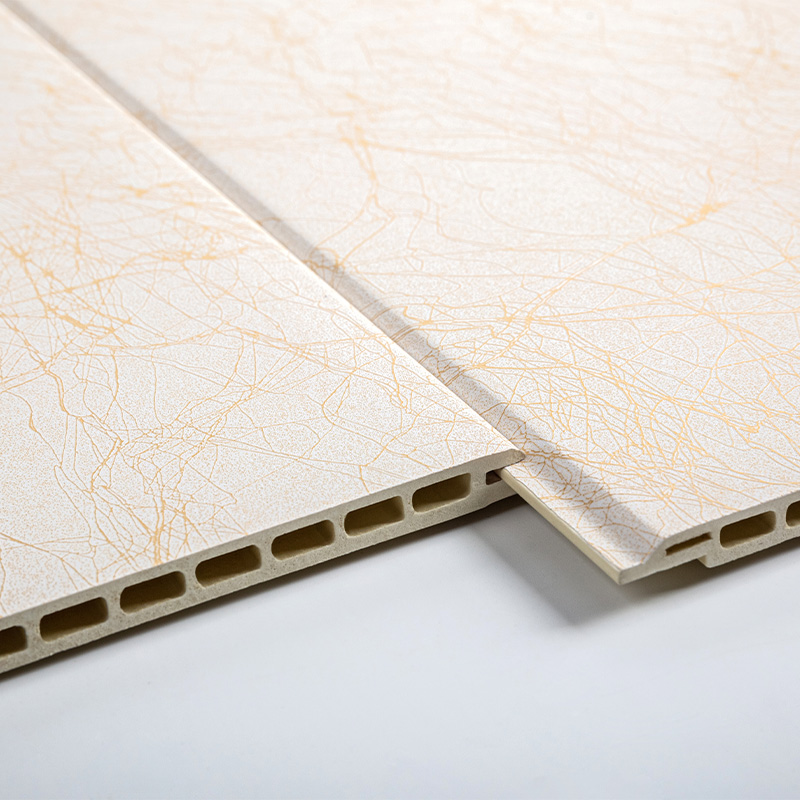

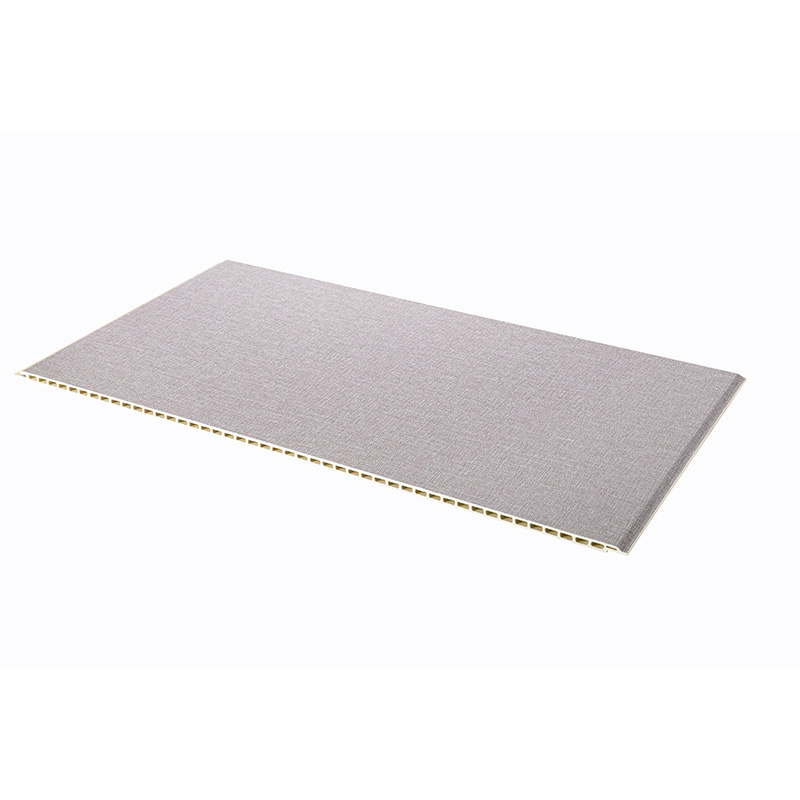

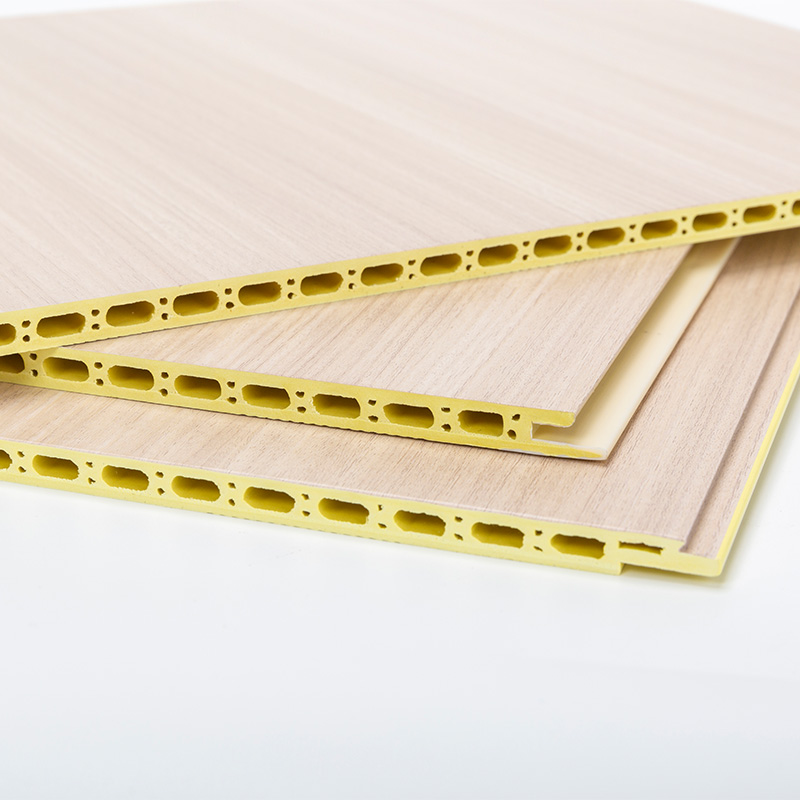

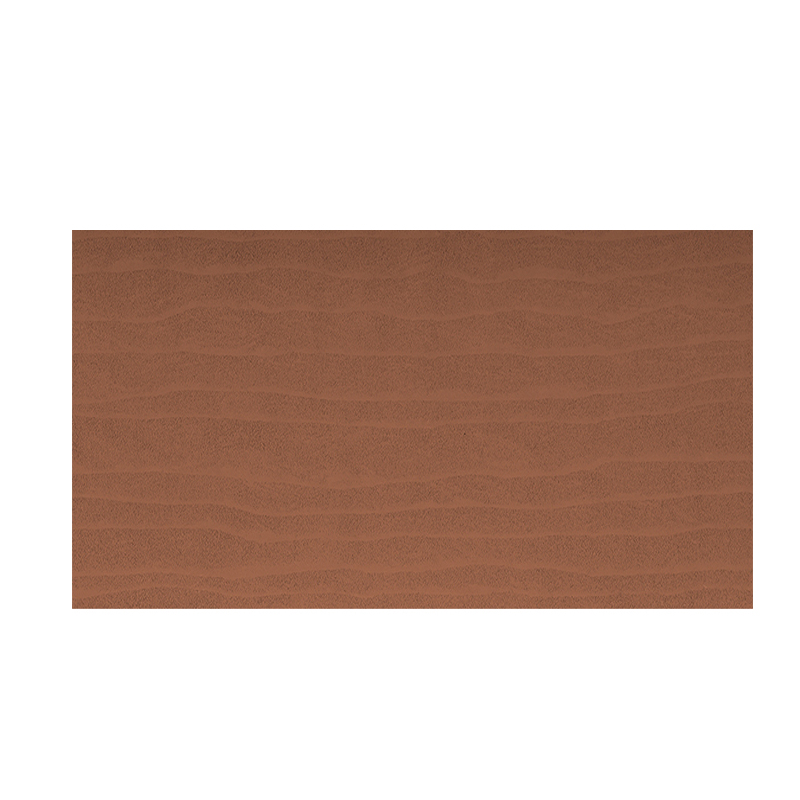

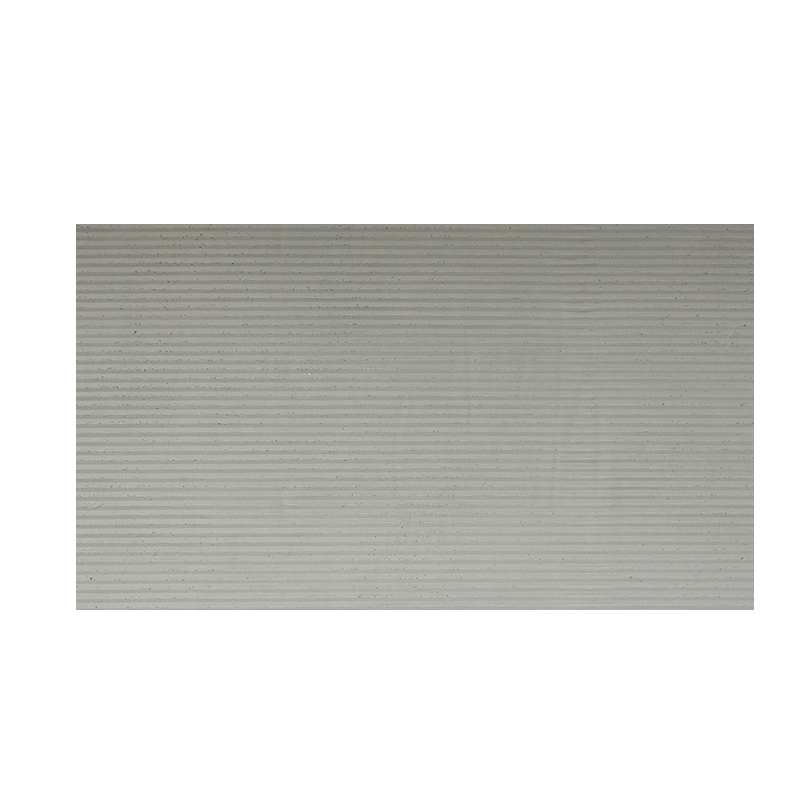

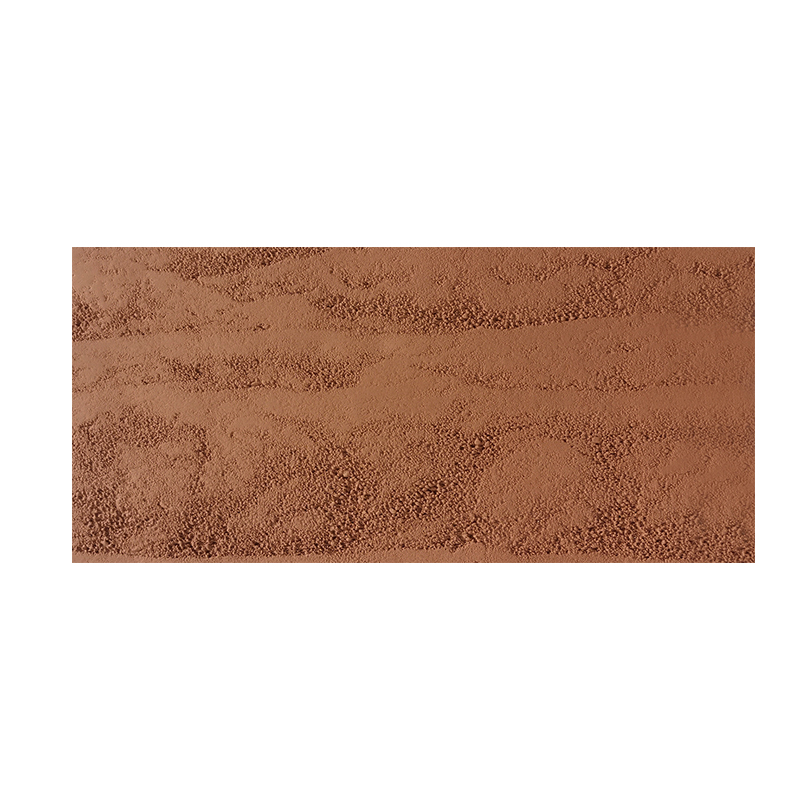

China YXWPC409-2 Eco-Friendly Board Wpc Wood Veneer Boards With Wood Texture For Hotel/House/Office Manufacturers and

YXWPC409-2 Eco-Friendly Board Wpc Wood Veneer Boards With Wood Texture For Hotel/House/Office Factory, we are a modern science and technology all-round enterprise focusing on the research and development, production, manufacturing, promotion and sales panels, ceilings, electrical appliances, flooring, and so on. It is located in Yuanhua Town, Haining City, Zhejiang Province, the origin of the ceiling in China. The company has 2 factories, nearly 20,000 square meters. The company has long been focusing on the independent research and development of panels and flooring, with the abundant product system in the industry. It can not only fully meet the needs of various styles of home decoration, but also meet the needs of various engineering projects, and is deeply loved and favored by the majority of consumers.