+86-18367343973

- 1 The Abrasion Benchmark: Optimal SPC Wall Cladding Wear Layer Thickness

- 2 Surface Integrity: Enhancing Durability with SPC Wall Cladding Commercial Wear Layer

- 3 Preserving Aesthetics: UV Coating Technology for SPC Cladding and Color Fastness

- 4 Haining Yunxi New Material Technology Co., Ltd.: Focus on Surface Excellence

- 5 Frequently Asked Questions (FAQ)

- 5.1 1. What is the recommended minimum SPC wall cladding wear layer thickness for heavy commercial use?

- 5.2 2. How is a panel's resistance to scratching and wear standardized?

- 5.3 3. What is the role of UV inhibitors in the UV coating technology for SPC cladding?

- 5.4 4. What makes an SPC wall cladding commercial wear layer technically superior to a residential one?

- 5.5 5. What is Color Fastness testing, and why is it important for the SPC wall cladding decorative film?

For B2B buyers and project developers, the performance of SPC wall cladding is not solely defined by its rigid stone-polymer core, but critically, by the integrity and durability of its surface layers. The key technical decision revolves around the optimal wear layer thickness and the quality of the UV coating used to protect the decorative print film. Ensuring long-term resilience requires a deep dive into the specifications governing the SPC wall cladding wear layer thickness.

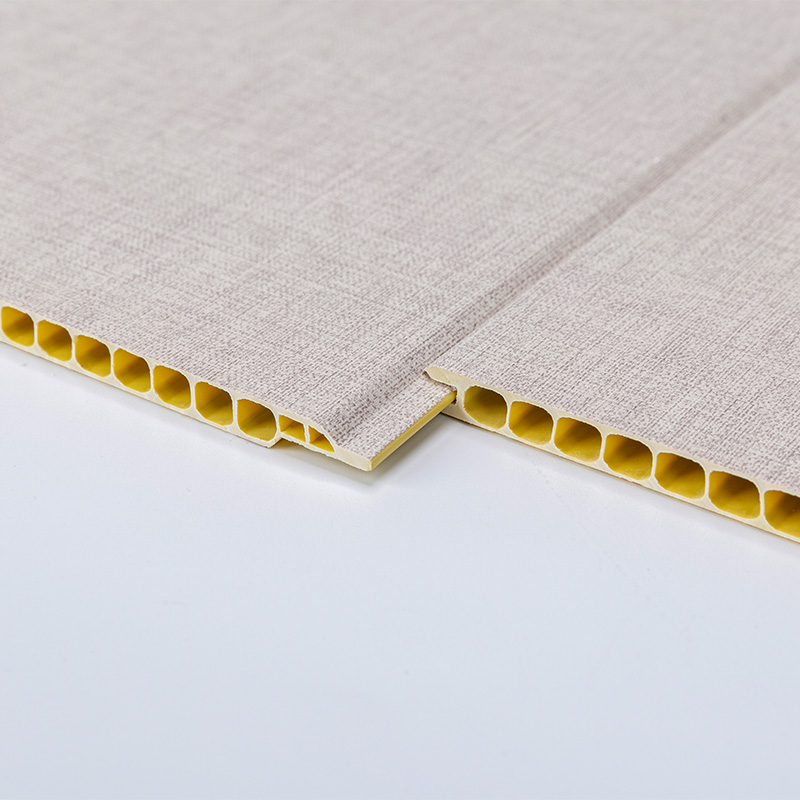

SPC Wall Panel - Click-Lock Easy Install Waterproof Panels for Bathroom & Kitchen YXSPC609-Y

The Abrasion Benchmark: Optimal SPC Wall Cladding Wear Layer Thickness

The wear layer is the transparent protective top layer that resists scratches, scuffs, and surface abrasion. Its thickness is the primary determinant of the panel's lifespan and its suitability for various traffic levels.

Wear Layer Micron Specifications for Residential vs. Commercial Use

- **Residential Use:** For low-traffic areas, a wear layer of 0.15 mm (150 microns) to 0.30 mm (300 microns) is typically sufficient.

- **Commercial Use:** High-traffic applications (hotels, offices, retail spaces) require a robust SPC wall cladding commercial wear layer of at least 0.40 mm (400 microns) to 0.70 mm (700 microns) to withstand constant physical contact and cleaning cycles.

Relating Wear Layer Thickness to SPC Wall Panel Abrasion Resistance Standards</HED

Abrasion resistance is technically measured by standardized tests, such as the Taber Abraser method (European Standard EN 13329), which determines the number of cycles required to wear through the protective layer. The specified wear layer thickness must correlate directly with established SPC wall panel abrasion resistance standards (often adapted from flooring grades).

Wear Layer Thickness vs. Application Table

| Wear Layer Thickness (Microns) | Application Category | Abrasion Class (Equivalent) |

|---|---|---|

| 150 microns - 300 microns | Light Residential / Decorative Wall | AC2 - AC3 (Low to Medium Use) |

| 400 microns | Medium Commercial / High Residential | AC4 (General Commercial Use) |

| 500 microns - 700 microns | Heavy Commercial / Industrial | AC5 (Heavy Commercial Use - Ideal SPC wall cladding commercial wear layer) |

Surface Integrity: Enhancing Durability with SPC Wall Cladding Commercial Wear Layer

Simply increasing the thickness of the wear layer is not enough; the material composition and curing process are vital technical factors in achieving premium durability.

Material Composition of High-Performance Wear Layers

- **Purity:** High-quality wear layers are typically constructed from clear PVC or proprietary polymer blends. The inclusion of aluminum oxide particles dramatically enhances the hardness and scratch resistance, which is especially required for a resilient SPC wall cladding commercial wear layer.

- **Flexibility:** The wear layer must also be flexible enough to withstand the slight movement and thermal expansion of the rigid SPC core without cracking or peeling, ensuring the longevity of the SPC wall cladding.

The Role of UV Curing and Cross-Linking in Abrasion Resistance

The UV coating applied over the wear layer is not merely cosmetic; it is cured using ultraviolet light to chemically cross-link the polymer chains. This process hardens the surface, drastically increasing the resistance to staining and light scratching beyond what the raw polymer film could provide. This dual-layer protection is a hallmark of high-grade wall paneling that meets SPC wall panel abrasion resistance standards.

Preserving Aesthetics: UV Coating Technology for SPC Cladding and Color Fastness

Visual fidelity over time is critical. The color and pattern must not fade or yellow, even under prolonged exposure to natural or artificial light. This is addressed by advanced print films and state-of-the-art UV coating technology for SPC cladding.

Understanding the Anti-fading properties of SPC wall panel (Color Fastness Testing)</HED

- **Test Standard:** Fade resistance is quantified using the Color Fastness to Light test (e.g., ISO 105-B02), which subjects the panel to intense artificial light simulating years of sun exposure. The result is measured against a blue wool scale.

- **UV Inhibitors:** High-quality SPC wall cladding utilizes specialized UV stabilizers and inhibitors mixed directly into the wear layer and the UV coating technology for SPC cladding. These chemical additives absorb and dissipate harmful UV radiation, ensuring the excellent Anti-fading properties of SPC wall panel.

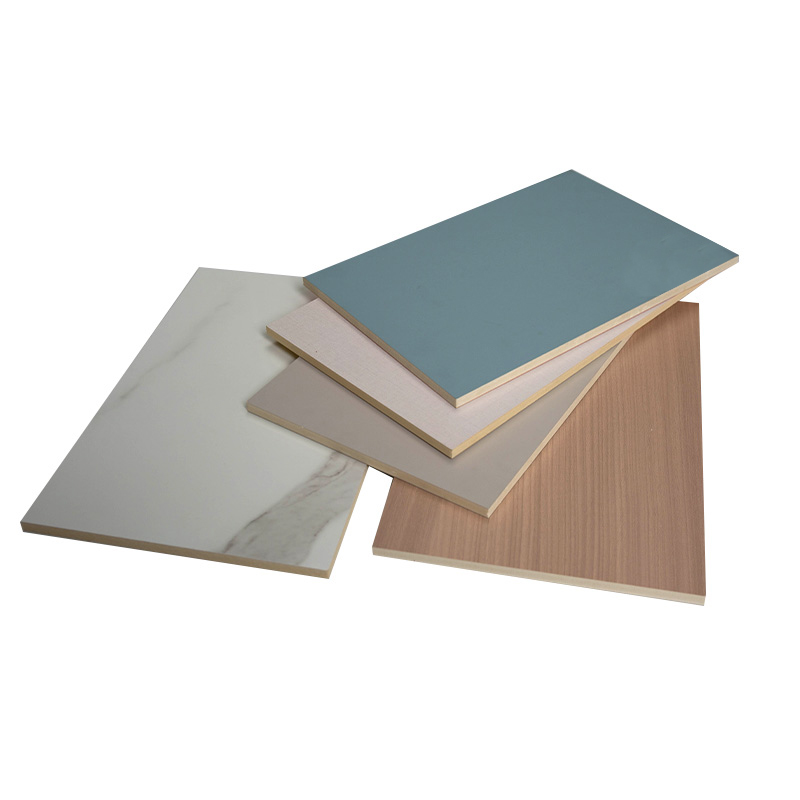

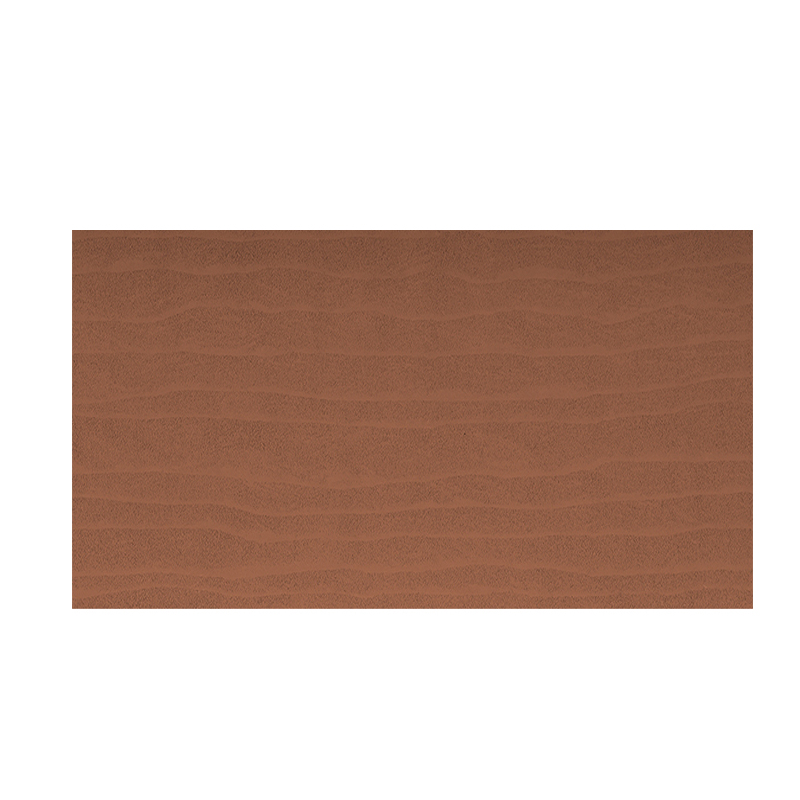

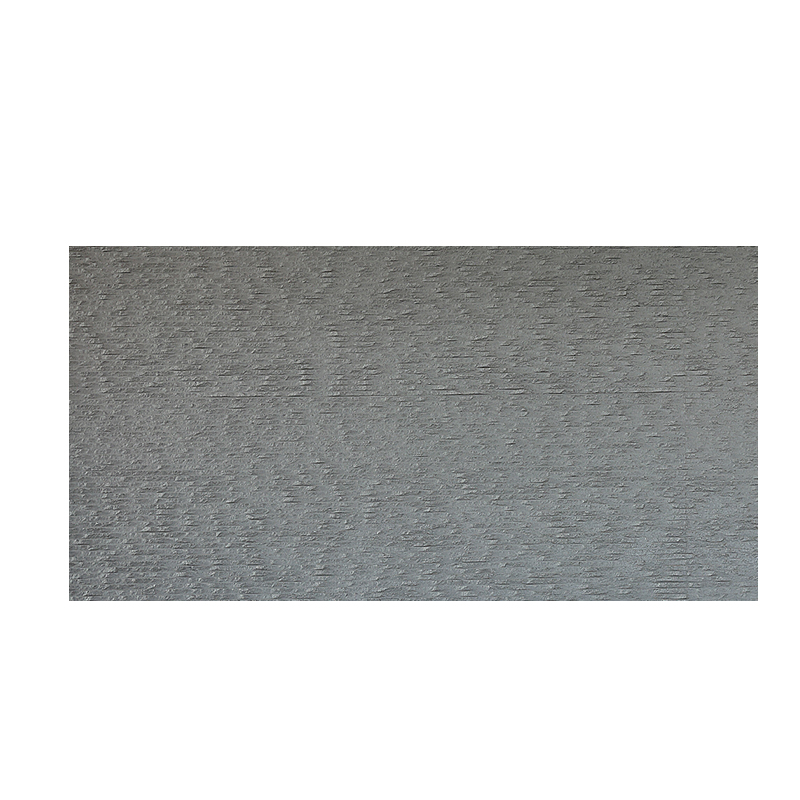

Advanced Embossing and Print Film Quality for Visual Realism

Visual realism is achieved through high-definition print film (the decorative layer) combined with EIR (Embossed in Register) technology. EIR uses precise alignment to synchronize the texture of the wear layer with the printed image, creating a tactile wood grain or stone texture that enhances the realism of the SPC wall cladding.

Haining Yunxi New Material Technology Co., Ltd.: Focus on Surface Excellence

Haining Yunxi New Material Technology Co., Ltd. has a long-standing focus on the independent research, development, and production of wood veneer wall panels and flooring, maintaining a rich product system. As a modern enterprise dedicated to all-round development, we recognize that the quality of the SPC wall cladding surface is paramount. Our technological innovation ensures that our products, loved by consumers and suitable for various construction projects, meet stringent SPC wall panel abrasion resistance standards. We utilize cutting-edge UV coating technology for SPC cladding to guarantee the long-term Anti-fading properties of SPC wall panel, providing our partners with products defined by both rapid development and unwavering quality.

Frequently Asked Questions (FAQ)

1. What is the recommended minimum SPC wall cladding wear layer thickness for heavy commercial use?

For heavy commercial applications, the minimum recommended SPC wall cladding wear layer thickness should be 0.50 mm (500 microns) or higher to achieve an equivalent abrasion class of AC5, ensuring longevity under high traffic.

2. How is a panel's resistance to scratching and wear standardized?

Abrasion resistance is standardized by measuring cycles required to penetrate the layer, often referencing EN 13329 (Taber Test). The resulting class rating (e.g., AC4 or AC5) is the key technical metric for SPC wall panel abrasion resistance standards.

3. What is the role of UV inhibitors in the UV coating technology for SPC cladding?

UV inhibitors are chemical additives mixed into the coating and wear layer. They absorb harmful ultraviolet radiation, preventing the decorative film from breaking down, which is essential for ensuring the Anti-fading properties of SPC wall panel over time.

4. What makes an SPC wall cladding commercial wear layer technically superior to a residential one?

A commercial wear layer is technically superior due to its greater thickness (higher micron count) and often the inclusion of hard particles like aluminum oxide, which significantly enhances resistance to scratching and frequent cleaning.

5. What is Color Fastness testing, and why is it important for the SPC wall cladding decorative film?

Color Fastness testing (e.g., ISO 105-B02) measures the panel's resistance to color change when exposed to intense light. It is crucial because the decorative appearance must remain consistent and not fade over the product's service life.