+86-18367343973

Introduction: Mitigating Moisture Risk in Modern Interiors

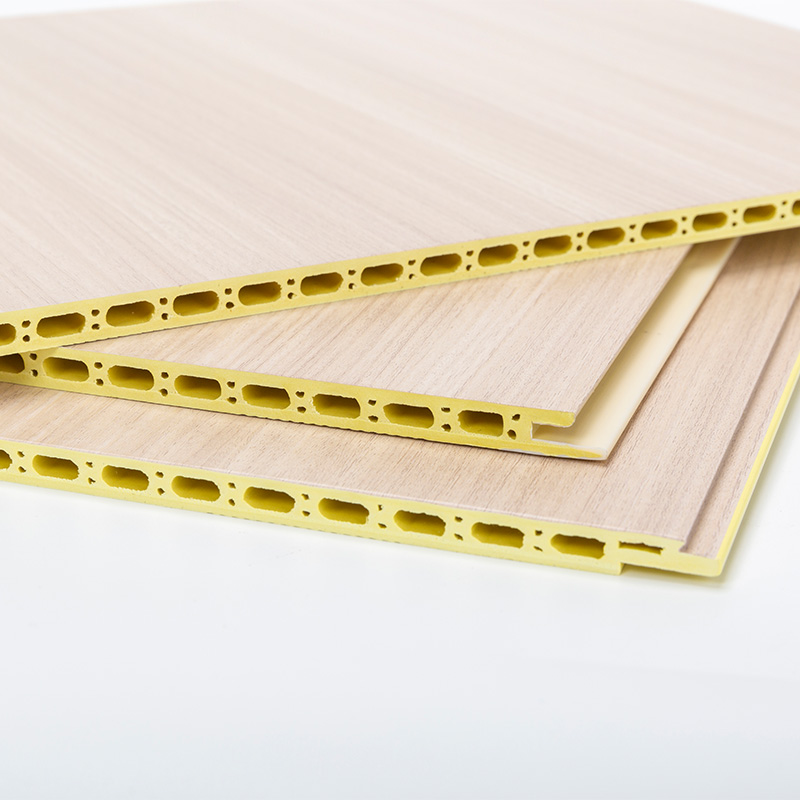

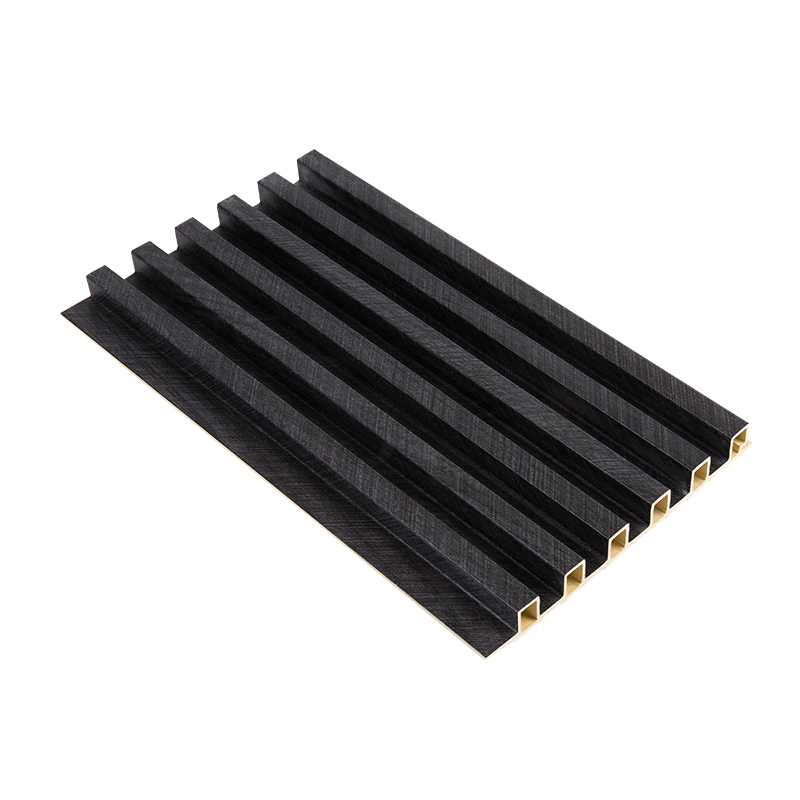

Moisture is the single greatest threat to the longevity and aesthetic appeal of interior finishes in areas like bathrooms, kitchens, and basements. For B2B specifiers and construction project managers, choosing a material with proven hydroscopic integrity is essential to prevent costly long-term failures like swelling, mold growth, and delamination. The **Interior WPC Wall Panel** (Wood Plastic Composite) has emerged as a preferred solution, but its performance depends critically on its water absorption rate and inherent anti-mold properties.

Haining Yunxi New Material Technology Co., Ltd. has a long-standing focus on the independent research and development and production of wall panels. With a rich product system in the industry, we aim not only to meet the needs of various styles of home decoration but also to satisfy the stringent requirements of construction projects. Our rapid pace of development in technological innovation and team management ensures we deliver panels engineered for performance in challenging environments.

Technical Validation of Moisture Resistance

Standardizing WPC wall panel water absorption rate testing

The **WPC wall panel water absorption rate testing** is the foundation of high-moisture suitability. This test, typically involving a 24-hour total immersion, quantifies the percentage of water absorbed by the material relative to its initial mass. For high-quality WPC designed for wet areas, this rate must be exceptionally low (often below 1%) because the thermoplastic PVC component effectively encapsulates the wood fiber, minimizing moisture ingress.

Long-term dimensional stability of WPC in wet areas

A low absorption rate is directly correlated with the **Long-term dimensional stability of WPC in wet areas**. Panels with high absorption rates will swell and shrink excessively, inevitably leading to joint separation, visible gaps, or bowing. By using materials with superior moisture resistance, specifiers ensure that the installation retains its visual and structural integrity over time, even with daily exposure to steam and splashing.

Comparison of WPC vs MDF in high humidity interiors

When selecting a core material for high humidity, the structural differences are critical. Standard wood-based panels like MDF (Medium Density Fiberboard) rely on organic fibers and adhesive binders, which are highly susceptible to swelling when exposed to moisture over time. In contrast, WPC uses a synthetic matrix, fundamentally altering its hydroscopic performance:

| Material Type | Core Composition | Water Absorption Risk | Swelling/Warping Potential |

| Interior WPC Wall Panel | PVC + Wood Powder Composite | Very Low (Encapsulated) | Very Low |

| MDF/HDF Panel | Wood Fibers + Resin Binder | High (Especially at edges) | High |

The WPC structure's inherent resistance makes it a far superior choice for applications where the **Comparison of WPC vs MDF in high humidity interiors** necessitates a material that will not degrade structurally.

Biological Defense: Mold and Mildew Control

Assessing Mold and mildew resistant interior WPC panel grades

Moisture resistance must be paired with biological resistance. A high-quality **Interior WPC Wall Panel** should offer **Mold and mildew resistant interior WPC panel** grades, often achieved through the incorporation of fungicidal additives into the PVC matrix, or by the panel's inherent nature of offering poor nutritional support for mold growth. B2B procurement should require anti-mold performance certification (e.g., based on standards like ASTM G21), confirming the material's ability to resist fungal colonization.

Surface Integrity and Sealing

While the core of the WPC is robust, the panel's surface film or protective coating is the first line of defense. This layer must be durable and continuous to prevent any moisture from reaching the composite core. Any minor defects or compromises in the surface film can negate the low **WPC wall panel water absorption rate testing** results achieved by the core material.

Practical Application and Installation Considerations

Best Practices for High-Moisture Installation

Even the **Best wall panel for bathroom and kitchen moisture** requires correct installation. Installers must prioritize sealing the perimeter joints (where the panel meets the floor, ceiling, or cabinets) using a flexible, mold-resistant sealant. While the panels themselves have low absorption, moisture ingress behind the panels can still occur if the perimeter is not fully sealed, potentially leading to issues on the substrate wall.

Quality Assurance and Procurement

As an all-round development modern enterprise, we continuously innovate to ensure our products meet the highest quality standards. Our rich product system, including our high-performance **Interior WPC Wall Panel**, allows us to fully meet the needs of various types of construction projects. By offering solutions that exhibit low absorption rates and proven resistance to mold, we attract the attention of the industry and earn the favor of consumers.

Conclusion: The Reliable Choice for Wet Areas

For B2B projects targeting high-humidity spaces, the selection criteria must be uncompromising. Verifying the low **WPC wall panel water absorption rate testing** and the **Mold and mildew resistant interior WPC panel** status is essential. By choosing a technologically advanced **Interior WPC Wall Panel**, specifiers invest in both superior aesthetics and long-term performance, confidently meeting the challenging demands of bathroom and kitchen moisture.

Frequently Asked Questions (FAQ)

- Can an Interior WPC Wall Panel be installed directly in a shower area? While WPC is highly moisture-resistant, it is generally recommended for areas outside the direct spray zone (like surrounding walls or ceilings). For direct shower walls, a fully waterproof system like tile or specialized shower panel with sealed joints is usually necessary.

- What specifically makes WPC more mold-resistant than wood panels? Mold requires organic nutrients to thrive. Since the wood powder in WPC is encapsulated by the non-organic PVC matrix, and the material may include fungicidal additives, it offers a much less hospitable environment for mold colonization compared to natural or engineered wood.

- What is the typical acceptable water absorption rate for a high-quality WPC panel? For an **Interior WPC Wall Panel** suitable for high-humidity areas, the typical acceptable water absorption rate after a 24-hour immersion test should be below 1.5%, with premium panels achieving rates close to 0.5% or lower.

- How does the low **WPC wall panel water absorption rate testing** relate to its cost? Generally, panels achieving lower absorption rates require higher quality PVC, more uniform compounding, and potentially higher-cost stabilizing/fungicidal additives. Therefore, superior moisture performance often correlates with a slightly higher initial purchase price, but lower long-term maintenance costs.

- If WPC is so water-resistant, why is the **Long-term dimensional stability of WPC in wet areas** still a concern? While WPC is highly resistant, any small amount of moisture absorption or prolonged, uneven temperature exposure can still induce internal stress. Maintaining stability requires high-quality compounding and ensuring the panel is not stressed during installation.