Product Features

- Moisture and Decay Resistance:The wood-plastic composite (WPC) formulation provides inherent resistance to water absorption, rot, and fungal growth, supporting its use in high-humidity interior applications and protected outdoor settings.

- Dimensional Stability:The composite material is engineered to maintain its structural integrity and profile with minimal expansion or contraction in response to temperature fluctuations.

- Low Maintenance Surface:The surface does not require periodic painting, staining, or sealing. Cleaning is accomplished with water and a mild detergent.

Product Description

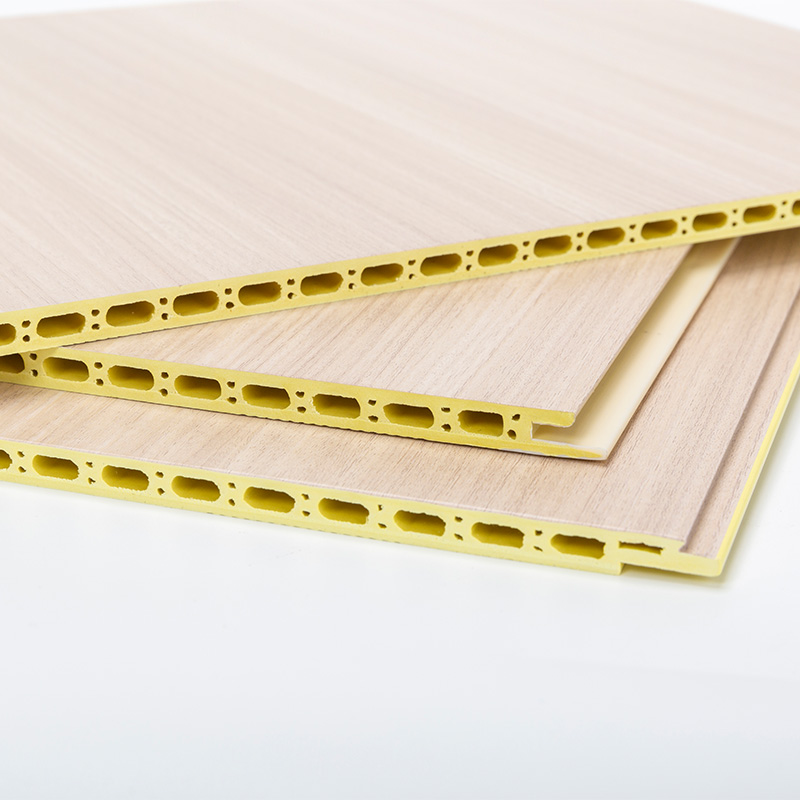

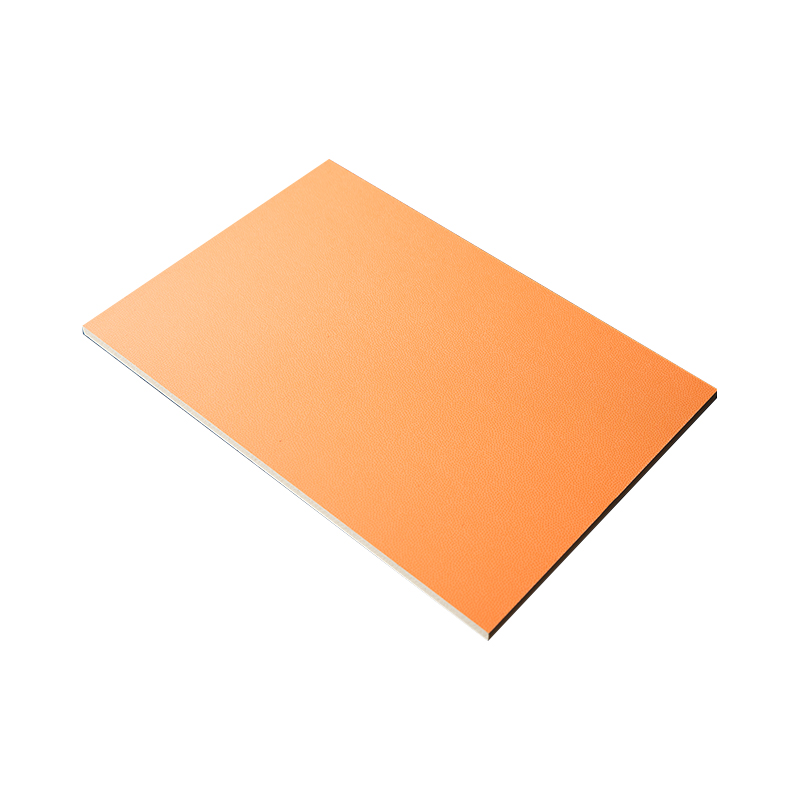

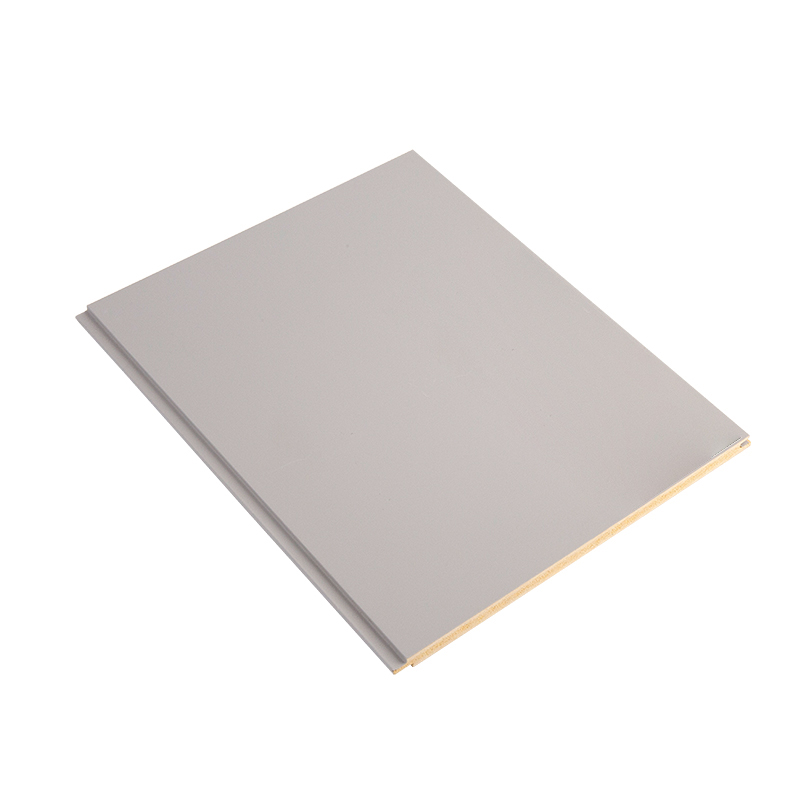

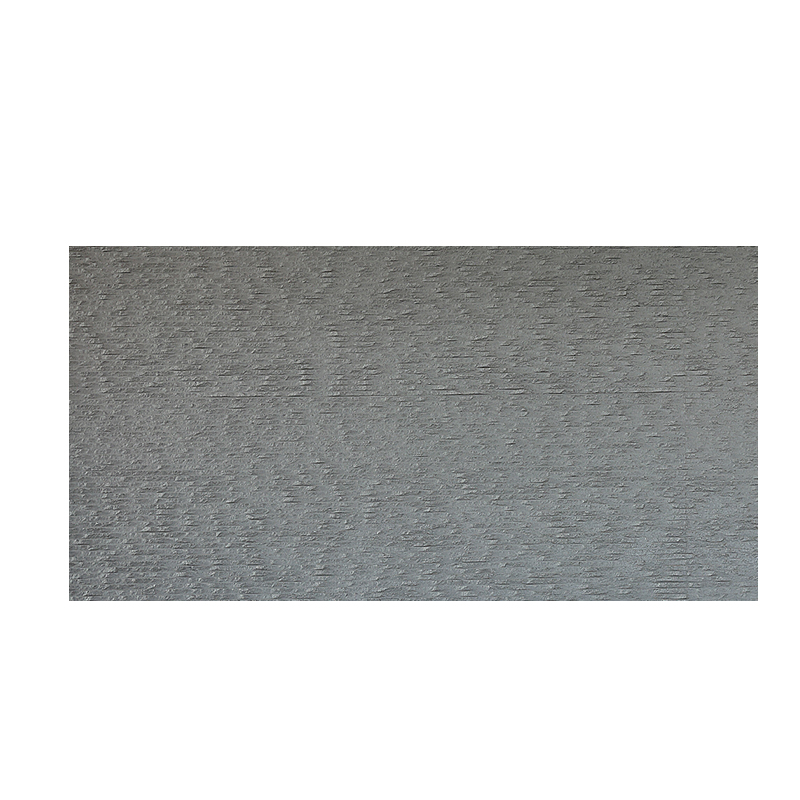

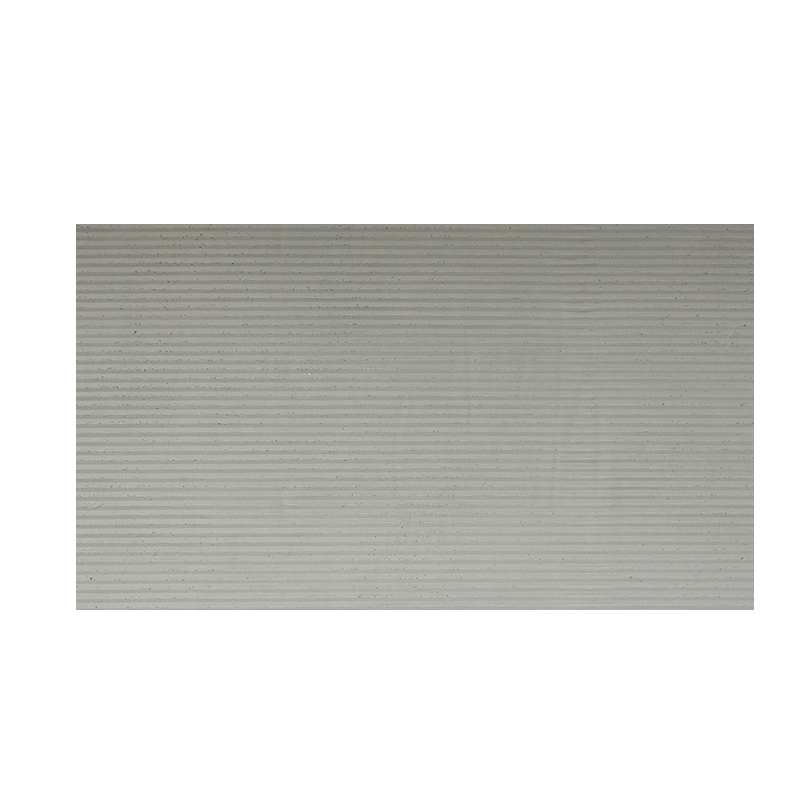

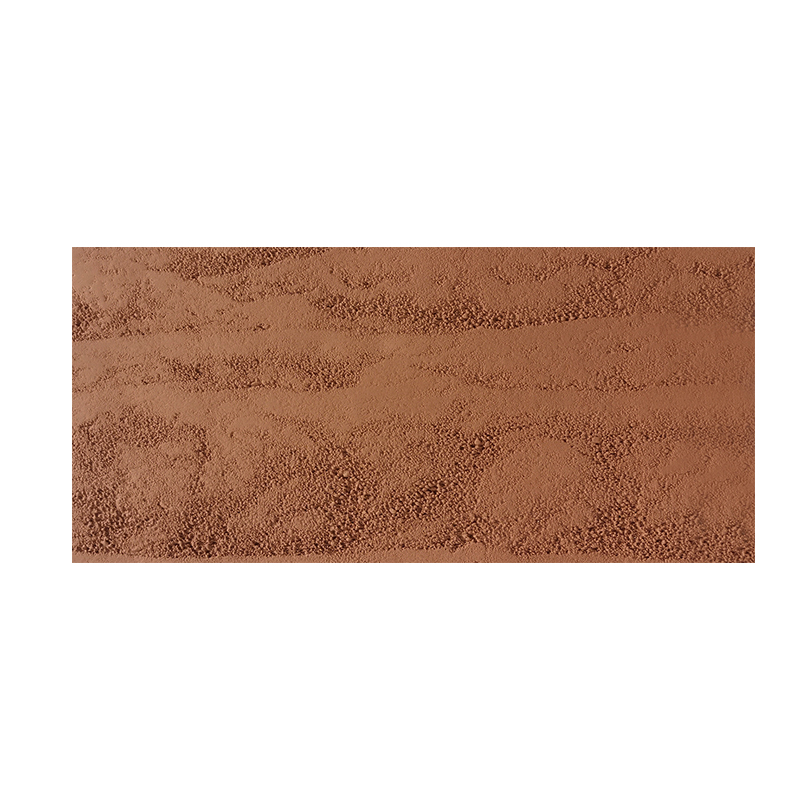

This wall decoration board is a wood-plastic composite (WPC) panel designed for interior and exterior wall cladding applications. It is manufactured through an extrusion process that combines wood flour and thermoplastic polymers, resulting in a material that exhibits properties of both components. The primary application is as a decorative and protective wall surface in commercial interiors, hospitality venues, and residential exteriors.

The production process adheres to industry standards for WPC extrusion, ensuring consistent density and profile accuracy. The formulation is designed to meet requirements for moisture resistance and mechanical strength in wall covering installations.

Technical Specifications

| Parameter |

Value |

Unit / Standard |

| Thickness |

5 |

mm |

| Width |

122 |

cm |

| Length |

240 |

cm (Customizable) |

| Material Composition |

Wood Plastic Composite (WPC) |

- |

| Density |

1.2 - 1.3 |

g/cm³ |

| Water Absorption (24h) |

< 0.8 |

% |

| Application Temperature Range |

-30 to 60 |

°C |

| Fire Rating |

Class B / C-s2, d0 |

EN 13501-1 |

Application Areas

This product is applicable for the following industrial and commercial scenarios:

- Feature walls and accent surfaces in retail environments and shopping malls.

- Wall cladding for bathrooms, kitchens, and spas where humidity resistance is a consideration.

- Exterior wall covering for residential buildings, balconies, and terraces (in protected applications).

- Interior wall panels for hotels, offices, and restaurants seeking a wood-effect finish with reduced maintenance.

FAQ

What is the recommended installation method for this WPC wall board?

Installation is typically performed using a concealed clip-and-track system or by direct fastening with stainless steel screws. An expansion gap of 5-10mm must be maintained at the ends of each panel to accommodate thermal movement. For exterior applications, a drained and ventilated cavity behind the boards is recommended to manage moisture and ensure long-term performance.

How does the performance of this WPC board compare to natural timber or PVC cladding?

This WPC board offers a balance of properties. Unlike natural timber, it does not require surface finishing to achieve moisture resistance and is less susceptible to warping or splintering. Compared to rigid PVC cladding, it typically has a higher density and a more matte, wood-like aesthetic. The thermal expansion coefficient is generally lower than that of pure PVC but higher than that of treated solid wood.

Can this panel be machined and cut on-site for custom installations?

Yes, the material can be processed using standard woodworking tools, including saws, routers, and drills. Carbide-tipped blades are recommended for cutting to ensure a clean edge. All cut edges should be considered unprotected; in applications with high exposure to water, a compatible sealant may be applied to the cut ends to maintain the product's waterproof properties.