Material and Process Analysis of Interior Decoration PVC Wall Panels

In modern residential and commercial design, Interior Decoration PVC Wall Panels are widely used for their lightweight, durability, water resistance, fire resistance, and easy installation. Understanding their material composition and production process helps designers, contractors, and consumers make informed decisions.

1. Material Composition

- PVC Core Material: Primarily made of polyvinyl chloride combined with reinforcing fibers and additives to enhance strength and stability.

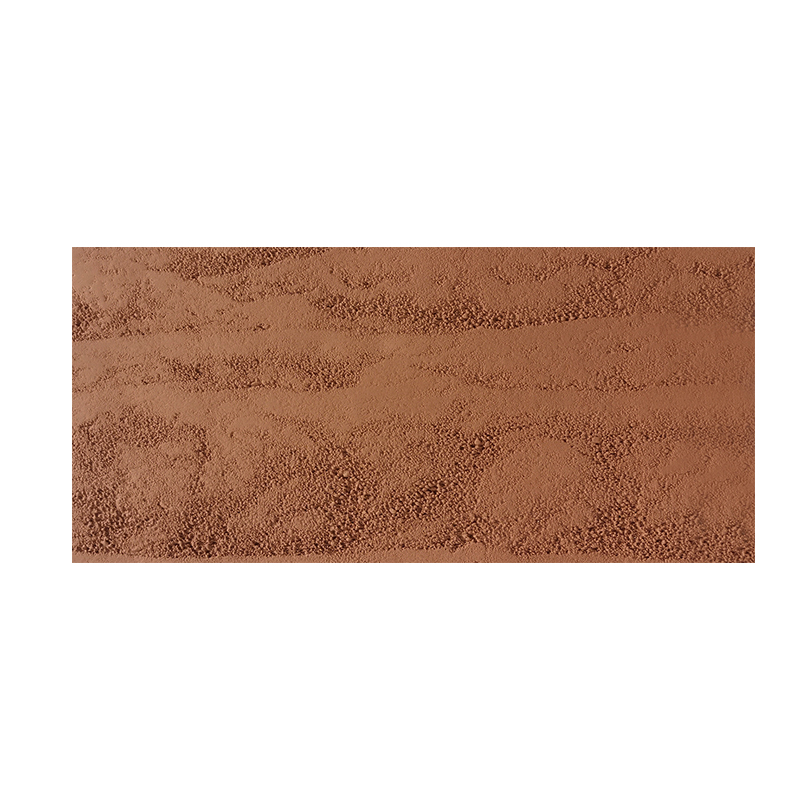

- Surface Decorative Layer: Can be printed or laminated to achieve various textures and colors, such as wood grain, marble, or solid colors.

- Reinforcement and Impact Layer: Improves impact and bending resistance, ensuring long-term durability.

Haining Yunxi New Material Technology Co., Ltd. has long focused on the R&D and production of wall panels and flooring, offering a comprehensive PVC wall panel product system that meets diverse home decoration and construction project requirements.

2. Surface Processes

- UV Printing and Lamination: Achieves a wide range of patterns and ensures wear resistance, waterproofing, and mold resistance.

- Scratch and Wear Layer: Protects the surface appearance and extends service life.

- Fire Treatment: Meets different fire resistance requirements, up to B1 or higher standards.

Yunxi's PVC wall panels combine advanced surface technologies, balancing aesthetics and functionality for various indoor environments.

3. Structure and Thickness

- Single-layer or multi-layer composite structure: Increases strength and stability, preventing deformation.

- Thickness range: Commonly 5–12mm, customizable according to project needs.

- Width and Length: Standard and non-standard sizes are available for easy installation and design integration.

4. Environmental and Safety Performance

- Low formaldehyde emissions meeting E0/E1 standards, ensuring indoor air quality.

- Recyclable materials align with modern green building concepts.

Haining Yunxi New Material Technology Co., Ltd. strictly controls environmental indicators during production to ensure healthy, green, and sustainable products.

5. Performance Comparison Table

| Parameter Category |

Indicator |

Common Standard |

Haining Yunxi New Material Technology Co., Ltd. Features |

| Core Material |

PVC + Reinforcing Fibers |

High-density PVC |

Selected materials, balancing strength and stability |

| Surface Decoration |

Printing/Lamination |

Wood grain, marble, solid colors |

Variety of textures and colors to meet different design needs |

| Impact Resistance |

Medium–High |

≥5kg impact test |

High-impact layer extends product lifespan |

| Thickness |

5–12mm |

5–12mm |

Customizable thickness for home and project requirements |

| Fire Rating |

B1 or above |

B1 |

Strict fire treatment enhances safety |

| Environmental Grade |

E0/E1 |

E0/E1 |

Strict formaldehyde control, healthy and eco-friendly |

| Installation Method |

Click/Adhesive |

Flexible |

Supports fast and convenient installation |

| Service Life |

5–15 years |

≥10 years |

High-quality materials and processes extend lifespan |

When selecting Interior Decoration PVC Wall Panels, it is important to consider material composition, surface process, thickness, structure, fire resistance, and environmental performance. With a comprehensive product system and strong R&D capabilities, Haining Yunxi New Material Technology Co., Ltd. provides high-quality, customizable PVC wall panel solutions that meet diverse residential and commercial project requirements and earn industry recognition.