+86-18367343973

- 1 I. Introduction: The Appeal and the Adhesion Challenge

- 2 II. Adhesive Technology and Bond Strength Verification

- 3 III. Substrate Compatibility and Preparation Requirements

- 4 IV. Environmental Factors and Performance Stability

- 5 V. Conclusion: Strategic Use of Self-Adhesive Systems

- 6 VI. Frequently Asked Questions (FAQ)

- 6.1 1. Is priming the subfloor necessary for all self-adhesive LVT installations?

- 6.2 2. How does the SPC core enhance the durability of the self-adhesive system?

- 6.3 3. What are the key differences in bond performance between self-adhesive and wet-set LVT?

- 6.4 4. Can self-adhesive LVT be installed over existing ceramic tile?

- 6.5 5. Does the inherent waterproof nature of the SPC plank mean it is immune to subfloor moisture issues?

I. Introduction: The Appeal and the Adhesion Challenge

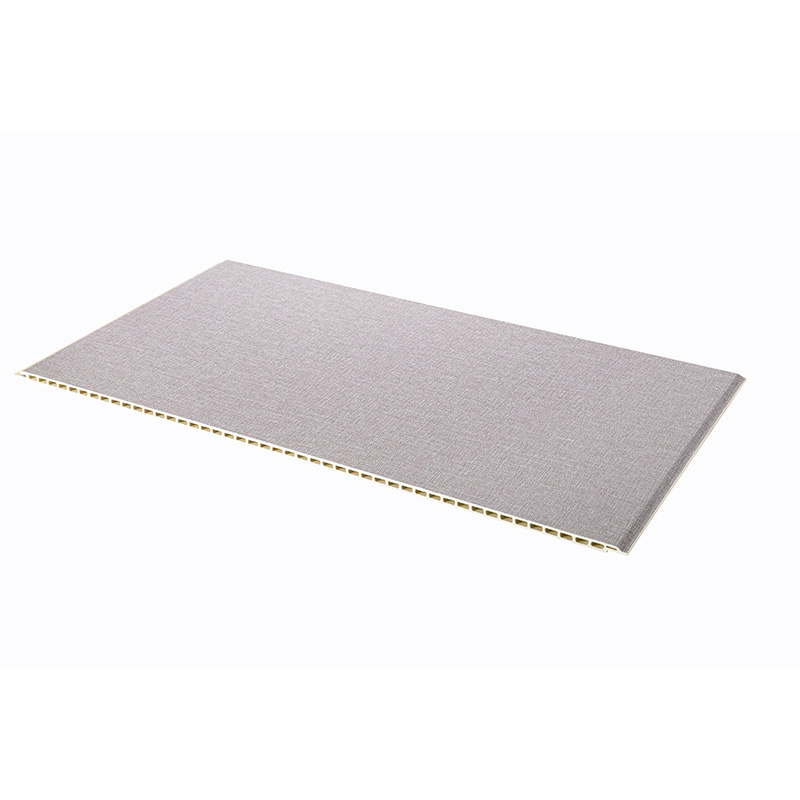

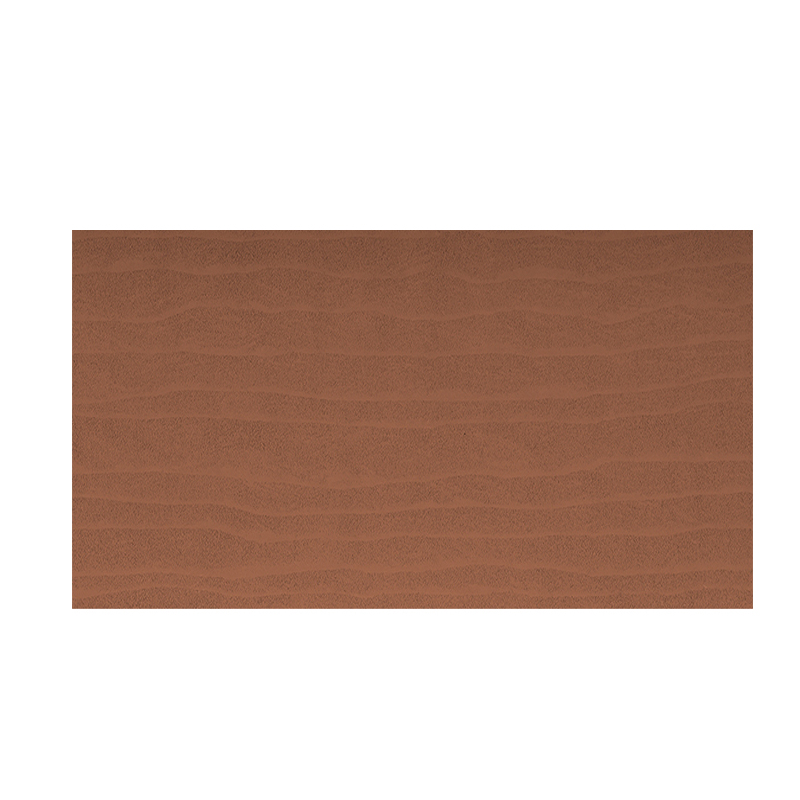

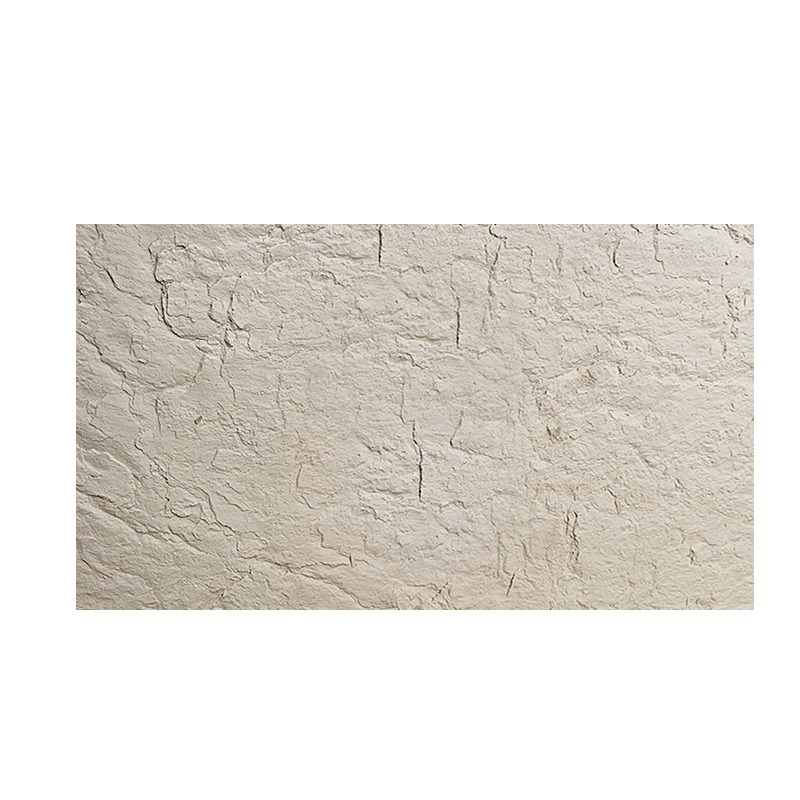

The market for flooring solutions is increasingly gravitating toward the PVC LVT Self-Adhesive Stone Plastic Composite Floor due to its promise of rapid, glue-free installation. This "peel-and-stick" convenience dramatically reduces labor time and complexity for construction projects. However, for B2B procurement, the key concern is not the ease of installation but the structural integrity of the long-term bond. Can the self-adhesive backing guarantee self-adhesive LVT floor long-term bond strength across various site conditions, and is it truly compatible with all subfloor types?

At Haining Yunxi New Material Technology Co., Ltd., we focus heavily on the independent research and development of flooring to meet the rigorous demands of construction projects. As a modern enterprise dedicated to technological innovation, our product system is engineered to provide not only aesthetic variety but also verifiable technical performance in every plank.

II. Adhesive Technology and Bond Strength Verification

The self-adhesive system utilizes a factory-applied, Pressure-Sensitive Adhesive (PSA), which adheres instantly upon contact. Unlike traditional wet-set adhesives, PSA relies on surface tack and high molecular cohesion rather than chemical curing. Verifying the quality of this bond is paramount for commercial viability.

A. Measuring Long-Term Bond Performance

Engineers quantify the technical performance of self-adhesive LVT floor long-term bond strength using specific metrics: Peel Strength (resistance to lifting from the edges) and Shear Strength (resistance to lateral movement). While PSA provides immediate tack and simplifies labor, its ultimate shear strength is typically lower than fully cured wet-set systems, making subfloor preparation critically important.

The choice between these systems hinges on the project's load requirements and preparation capability. For high-traffic commercial spaces requiring maximum lateral stability, wet-set often remains the engineering standard, whereas self-adhesive is ideal for quick, low-impact installations.

| Adhesive System | Primary Bonding Mechanism | Ultimate Shear Strength | Installation Time/Complexity |

|---|---|---|---|

| Self-Adhesive (PSA) | Surface Tack & Cohesion | Moderate (Lower than Wet-Set) | Fast, Low Labor |

| Wet-Set (Chemical Cure) | Chemical Curing & Mechanical Key | High (Superior Lateral Stability) | Slow, High Labor |

B. Assessing Self-Stick Durability in Commercial Settings

For B2B applications, we test Self-stick LVT peel-and-stick durability B2B against worst-case scenarios, including sustained heavy rolling loads (office chairs, equipment) and sudden impact. A robust self-adhesive system, particularly when combined with a Stone Plastic Composite (SPC) core known for dimensional stability, must resist edge curl and lifting, even after years of continuous stress. Any failure in the bond strength directly leads to product failure, regardless of the panel's core quality.

III. Substrate Compatibility and Preparation Requirements

The critical limitation of the self-adhesive system is its non-negotiable dependence on the substrate's condition. Self-adhesive flooring is only as strong as the surface it adheres to, meaning it is not universally compatible without preparation.

A. Critical Substrate Surface Criteria

To guarantee a strong bond, the substrate must meet stringent criteria for flatness (to prevent stress on the bond), pH (to avoid adhesive breakdown), and residual moisture. The SPC self-adhesive flooring subfloor preparation guide mandates that the surface must be clean, dry, dust-free, and structurally sound. Any contaminants (dust, oil, old adhesive residue) compromise the adhesive's ability to achieve full surface contact and significantly reduce self-adhesive LVT floor long-term bond strength.

B. Substrate Specificity and Suitability

While the LVT/SPC plank itself is durable, the self-adhesive backing has limitations concerning Substrate compatibility for self-adhesive LVT. Porous materials like raw concrete often require a sealer and/or primer, while non-porous, smooth surfaces (like existing ceramic tile with wide grout lines) require a leveling compound to ensure the adhesive achieves the required full-surface contact.

| Substrate Type | Subfloor Preparation Requirement | Self-Adhesive Suitability |

|---|---|---|

| Raw Concrete (Dry) | Sealing and Primer (Mandatory) | Moderate (High dependency on primer quality) |

| Existing Sheet Vinyl (Solid) | Clean and Degrease | High |

| Existing Ceramic Tile | Grout lines must be filled and leveled | Low (Not suitable without leveling) |

IV. Environmental Factors and Performance Stability

The surrounding environment plays a decisive role in the long-term performance and Self-stick LVT peel-and-stick durability B2B rating.

A. Moisture Ingress and Hydrostatic Pressure

Although the core of a PVC LVT Self-Adhesive Stone Plastic Composite Floor is waterproof, the adhesive layer is not immune to moisture. The Moisture resistance of self-adhesive SPC plank refers primarily to the plank itself. High moisture vapor transmission rate (MVTR) from below the slab can cause the adhesive to re-emulsify or lose its tack over time, leading to bond failure and edge lifting. For areas prone to hydrostatic pressure, a traditional perimeter-lock or full-spread glue-down system is often the more reliable engineering choice.

B. Thermal Cycling and Dimensional Stability

Temperature fluctuations (thermal cycling) place mechanical stress on both the adhesive and the panel. While the SPC core offers excellent dimensional stability compared to older LVT, extreme temperature swings (e.g., in unheated storage facilities or seasonal sun exposure near windows) can fatigue the PSA layer, accelerating the deterioration of the self-adhesive LVT floor long-term bond strength.

V. Conclusion: Strategic Use of Self-Adhesive Systems

The self-adhesive system of the PVC LVT Self-Adhesive Stone Plastic Composite Floor offers a powerful solution for projects prioritizing speed and simplicity, provided its technical limitations are respected. Guaranteeing self-adhesive LVT floor long-term bond strength is achieved not by the product alone, but through strict adherence to the SPC self-adhesive flooring subfloor preparation guide and a thorough understanding of Substrate compatibility for self-adhesive LVT. Haining Yunxi New Material Technology Co., Ltd. provides comprehensive product systems and technical insight, ensuring our partners benefit from the convenience and Moisture resistance of self-adhesive SPC plank while maintaining the highest level of installation durability and Self-stick LVT peel-and-stick durability B2B.

VI. Frequently Asked Questions (FAQ)

1. Is priming the subfloor necessary for all self-adhesive LVT installations?

- A: Priming is highly recommended, especially on porous or dusty concrete surfaces. The primer seals the substrate, improves tack, and is a critical step in the SPC self-adhesive flooring subfloor preparation guide to ensure self-adhesive LVT floor long-term bond strength and prevent dust from interfering with the adhesive.

2. How does the SPC core enhance the durability of the self-adhesive system?

- A: The Stone Plastic Composite (SPC) core provides exceptional dimensional stability. This stability minimizes the panel's expansion and contraction due to temperature changes, which significantly reduces the stress transferred to the adhesive layer. This aids in Self-stick LVT peel-and-stick durability B2B by preventing bond fatigue.

3. What are the key differences in bond performance between self-adhesive and wet-set LVT?

- A: The primary difference is shear strength. While self-adhesive (PSA) provides immediate tack and fast installation, chemically cured wet-set adhesives provide superior ultimate shear strength, making them generally better for high-rolling-load commercial environments.

4. Can self-adhesive LVT be installed over existing ceramic tile?

- A: Direct installation is strongly discouraged due to poor Substrate compatibility for self-adhesive LVT. The wide grout lines create uneven stress points, leading to bond failure and plank indentation. The surface must first be leveled using a self-leveling compound, as mandated by the SPC self-adhesive flooring subfloor preparation guide.

5. Does the inherent waterproof nature of the SPC plank mean it is immune to subfloor moisture issues?

- A: No. While the Moisture resistance of self-adhesive SPC plank core prevents water damage to the plank itself, high moisture vapor transmission from the subfloor can degrade the self-adhesive layer over time, causing it to fail. For high-moisture risk areas, a specific moisture barrier must be applied to the subfloor.