+86-18367343973

- 1 I. Engineering Durability from the Top Down

- 2 II. The Mechanics of the Wear Layer: Composition and Performance Standards

- 3 III. Durability and Lifespan: A Quantitative Analysis

- 4 IV. Maintenance, Cost, and Operational Efficiency

- 5 V. Specification Guidance for Procurement

- 6 VI. Conclusion: The Wear Layer as an Investment

- 7 VII. Frequently Asked Questions (FAQ)

- 7.1 1. What is the minimum recommended wear layer thickness for heavy commercial use?

- 7.2 2. How does the wear layer impact the floor's slip resistance?

- 7.3 3. Is a self-adhesive installation method suitable for a high-traffic area?

- 7.4 4. Can a thin wear layer be refreshed or refinished?

- 7.5 5. What is the "mil" unit and how does it relate to millimeter thickness?

I. Engineering Durability from the Top Down

For B2B buyers, procurement decisions for flooring, such as the advanced PVC LVT Self-Adhesive Stone Plastic Composite Floor, must be grounded in precise technical specifications rather than aesthetic appeal alone. The single most critical component determining the floor's long-term performance, resistance to traffic, and ultimate cost-efficiency is the wear layer.

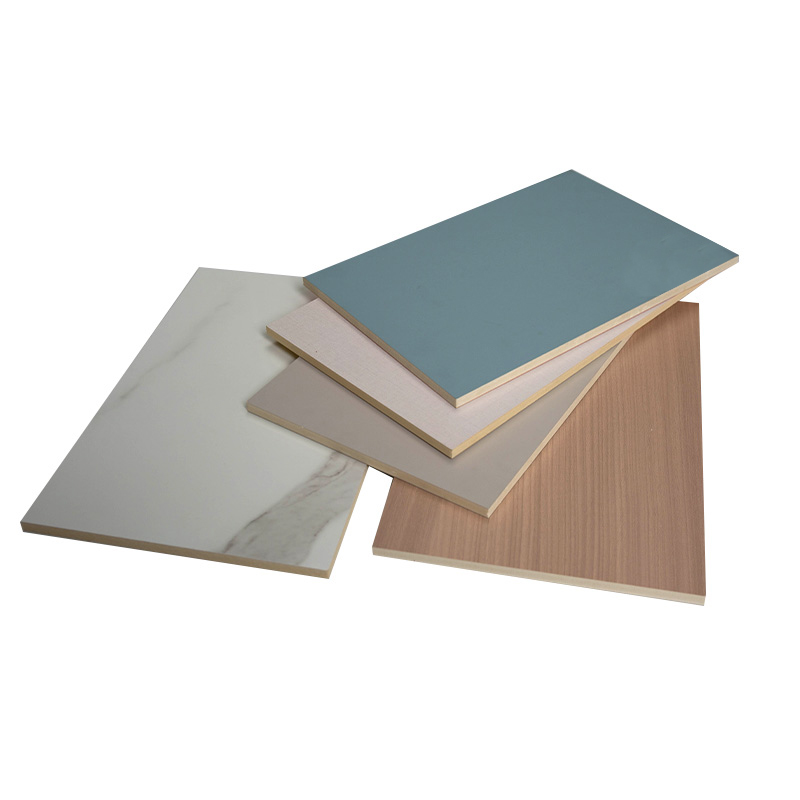

At Haining Yunxi New Material Technology Co., Ltd., we have long focused on the independent research and development and production of wood veneer wall panels and flooring, cultivating a rich product system in the industry. Our commitment is to provide products that fully meet the needs of various styles of home decoration and, crucially, the rigorous demands of various types of construction projects. This starts with engineering the wear layer to meet the specific performance metrics required by the project scope, directly addressing concerns like the viability of a long-term 0.5mm wear layer SPC flooring lifespan estimation in a commercial setting.

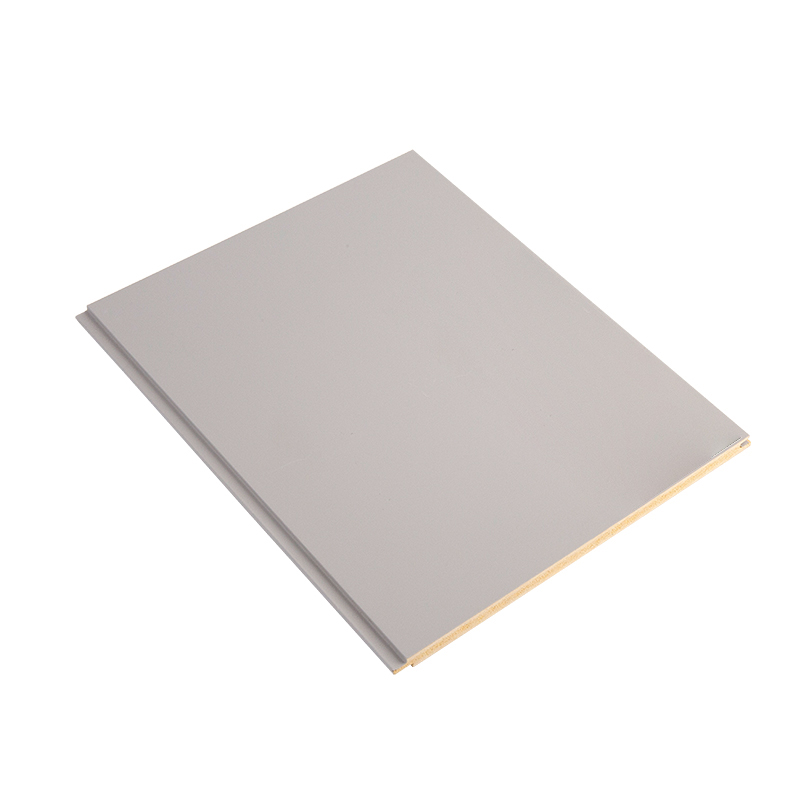

Waterproof, moisture-proof and impact-resistant home decoration SPC flooring Thickness 5 YXSPC22950

II. The Mechanics of the Wear Layer: Composition and Performance Standards

The wear layer is the transparent, protective top coating that guards the decorative film beneath it. Its composition is typically a Urethane-based finish, often fortified with micro-particles of ceramic bead or Aluminum Oxide. This fortification is not merely a coating; it is a meticulously engineered barrier designed to withstand mechanical friction and chemical interaction.

EN/ISO Classification: The Technical Benchmark

In the global flooring industry, the performance of the wear layer is quantified by the European Standard (EN) and International Organization for Standardization (ISO). These standards classify flooring based on its suitability for use, which is essential for B2B procurement:

- Class 20s (Residential): Lighter traffic areas (e.g., bedrooms).

- Class 30s (Commercial): Moderate to heavy public areas (e.g., offices, boutiques). Class 33 is the standard for heavy commercial use.

- Class 40s (Industrial): Very heavy/light industrial traffic (e.g., warehouses, manufacturing facilities).

The classification achieved (e.g., EN ISO 10582 and EN ISO 23999) is directly linked to the thickness and abrasion rating of the wear layer. A 0.7mm wear layer, for example, is almost exclusively necessary for achieving the Class 33 and Class 42 ratings essential for high-volume commercial installations.

III. Durability and Lifespan: A Quantitative Analysis

The relationship between wear layer thickness and long-term durability is nearly linear. The thickness provides the physical volume necessary to resist removal via abrasion. Abrasion resistance is measured technically via the EN 660-2 standard (Taber Abraser test), which determines the number of cycles required to wear through the surface layer.

Comparing Common B2B Wear Layer Specifications

For the B2B market, wear layer thicknesses are typically measured in increments of tenths of a millimeter. The selection dictates the appropriate application environment. Below is a comparison of how wear layer thickness impacts a floor's suitability. This addresses a fundamental component of defining commercial grade self-adhesive SPC flooring specifications.

A thinner layer may be suitable for lighter commercial use, but a thicker layer is mandatory for long-term viability in high-traffic retail or educational environments. The physical volume of the wear layer provides the buffer against the cumulative effects of mechanical stress.

Wear Layer Thickness vs. Application Suitability Comparison

| Wear Layer Thickness | Corresponding EN/ISO Class (Approx.) | Suitable Application Environment | Estimated Service Life (Commercial) |

|---|---|---|---|

| 0.3mm (12 mil) | Class 23/31 (Light Commercial) | Hotel Rooms, Small Offices, Multi-Family Residential | 5 - 8 Years |

| 0.5mm (20 mil) | Class 32/33 (General Commercial) | Retail Boutiques, Doctor's Offices, Class A Office Space | 10 - 15 Years (Baseline for heavy use) |

| 0.7mm (28 mil) | Class 33/42 (Heavy/Industrial Commercial) | Grocery Stores, Hospitals, Educational Facilities, Airports | 15 - 20+ Years |

IV. Maintenance, Cost, and Operational Efficiency

The wear layer thickness critically influences the Total Cost of Ownership (TCO) beyond the initial purchase price. A thicker wear layer directly reduces the frequency and intensity of required maintenance, proving that a higher upfront investment can yield significant long-term operational savings. This speaks directly to the impact of wear layer on LVT flooring maintenance cost.

The Cleaning Protocol Advantage

- Thicker Wear Layer (0.5mm and above): Allows for the safe use of more aggressive chemical cleaners and heavier-duty scrubbing equipment (e.g., rotary buffers). The robust layer protects the core and print film from being damaged by deep cleaning necessary in demanding environments. This extends the aesthetic life of the PVC LVT Self-Adhesive Stone Plastic Composite Floor.

- Thinner Wear Layer (0.3mm and below): Requires gentler, less effective cleaning agents and lighter equipment to avoid micro-scratching or etching, which can lead to premature dulling and the need for earlier replacement.

Self-Adhesive vs. Click-System Durability Considerations

While the focus is on the wear layer, B2B purchasers must also consider the installation mechanism. The wear layer on a self-adhesive product must be robust enough to justify the simplified installation. In a LVT click vs self-adhesive durability comparison, both formats can feature the same critical wear layer thickness (e.g., 0.5mm or 0.7mm). Therefore, the wear layer's quality ensures that the self-adhesive mechanism (which is highly favored for certain rapid-deployment projects) does not compromise the surface performance.

V. Specification Guidance for Procurement

Procurement must be based on a pragmatic calculation: traffic volume $\times$ intended lifespan $=$ required wear layer thickness. Haining Yunxi New Material Technology Co., Ltd., as an all-round development of a modern enterprise, offers guidance tailored to diverse project scales.

Targeted Recommendations: An SPC flooring wear layer thickness guide

To assist in specifying the correct product, we provide the following SPC flooring wear layer thickness guide minimums:

- High-Frequency Public Areas (e.g., Airports, High Street Retail): Minimum 0.7mm wear layer is mandatory.

- General Commercial Offices/Mid-Scale Retail: Minimum 0.5mm wear layer is the industry standard.

- Light Commercial/Specialty Boutiques: A 0.3mm wear layer may be acceptable, but only where budget constraints outweigh the desire for maximum lifespan.

Our rich product system, built upon continuous technological innovation and team management excellence, is designed to align a customer's project budget with the necessary technical specifications for long-term satisfaction.

VI. Conclusion: The Wear Layer as an Investment

The wear layer of a PVC LVT Self-Adhesive Stone Plastic Composite Floor is not merely a component; it is an investment in a project's long-term operational efficiency and aesthetic integrity. For B2B buyers and wholesalers, understanding the technical specifications—particularly the wear layer thickness—is paramount. By specifying a wear layer that exceeds the projected traffic requirements (e.g., a 0.7mm layer where a 0.5mm is the minimum), you drastically extend the product's service life and minimize the total cost of ownership over two decades.

VII. Frequently Asked Questions (FAQ)

1. What is the minimum recommended wear layer thickness for heavy commercial use?

The minimum recommended wear layer thickness for heavy commercial applications (Class 33 and above) is 0.5mm (20 mil). For extreme traffic environments such as hospitals or department stores, a 0.7mm (28 mil) wear layer is strongly advised to ensure a 15-20 year service life, as outlined in the 0.5mm wear layer SPC flooring lifespan estimation data.

2. How does the wear layer impact the floor's slip resistance?

While the primary function of the wear layer is abrasion resistance, it is also integral to the slip-resistant properties of the floor. The finish (or texture) applied to the wear layer, often enhanced by additives, determines the coefficient of friction (COF), which is crucial for safety in commercial spaces.

3. Is a self-adhesive installation method suitable for a high-traffic area?

Yes, provided the wear layer is appropriately thick (0.5mm or 0.7mm). The surface durability is independent of the installation type. In a LVT click vs self-adhesive durability comparison, the self-adhesive method is durable for high traffic when coupled with a high-grade commercial grade self-adhesive SPC flooring specifications wear layer and a properly prepared subfloor.

4. Can a thin wear layer be refreshed or refinished?

Unlike wood, the plastic wear layer on a PVC LVT Self-Adhesive Stone Plastic Composite Floor cannot be sanded or deep-refinished. Only a robust wear layer (0.5mm+) can withstand periodic chemical stripping and recoating with a polymer finish. If the wear layer is too thin, it cannot be effectively maintained, reinforcing the need to consult the SPC flooring wear layer thickness guide.

5. What is the "mil" unit and how does it relate to millimeter thickness?

The "mil" is a common unit in North America, representing one-thousandth of an inch (0.001"). The conversion is approximately: 1 mil $\approx$ 0.0254 mm. For example, the industry standard 20 mil is equivalent to 0.5mm, a key benchmark in the commercial grade self-adhesive SPC flooring specifications.