+86-18367343973

- 1 I. The Demand for Durability in Flooring

- 2 II. Waterproof Performance: Core Composition and Sealing

- 3 A. Core Water Resistance: SPC vs. Standard LVT

- 4 B. Surface and Installation Sealing

- 5 III. Thermal Stability: High and Low-Temperature Resilience

- 6 A. High-Temperature Performance and Heat Resistance

- 7 B. Cold Environment Integrity

- 8 IV. Engineering for Long-Term Dimensional Stability

- 9 A. Measuring Stability: The Role of the SPC Core

- 10 B. The Adhesion Factor in Thermal Movement

- 11 V. Performance-Driven Composite Flooring

- 12 VI. Frequently Asked Questions (FAQ)

- 12.1 1. How does the SPC core prevent water damage compared to standard LVT?

- 12.2 2. Can this flooring be installed in unheated spaces like cottages or seasonal rooms?

- 12.3 3. What temperature limitations should B2B installers be aware of for heat resistance?

- 12.4 4. Does the self-adhesive nature impact the floor's ability to handle topical moisture?

I. The Demand for Durability in Flooring

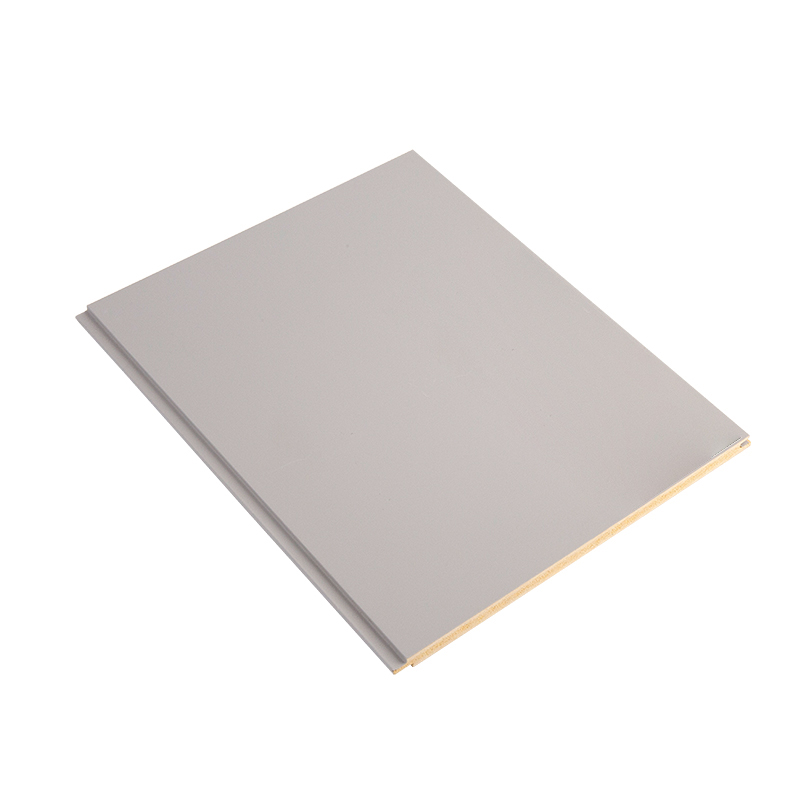

Modern construction and renovation projects demand flooring materials that offer a perfect blend of aesthetic appeal, simplified installation, and uncompromising resilience against environmental factors. The PVC LVT Self-Adhesive Stone Plastic Composite Floor meets this high bar by integrating the ease of a self-adhesive application with the structural robustness of a Stone Plastic Composite (SPC) core. The key technical challenges for this product center on two areas: achieving true waterproof performance and preventing warping or gapping under extreme temperature variations.

Haining Yunxi New Material Technology Co., Ltd. has a long-standing focus on the independent research, development, and production of flooring and wall panels, establishing a rich product system. Our rapid technological innovation and development pace ensure that our flooring not only meets diverse home decoration needs but also the stringent requirements of various large-scale construction projects, cementing our position as an all-round modern enterprise.

II. Waterproof Performance: Core Composition and Sealing

The term "waterproof" is often misapplied in the flooring industry. For the PVC LVT Self-Adhesive Stone Plastic Composite Floor, true waterproof integrity stems from the material composition of its core layer.

A. Core Water Resistance: SPC vs. Standard LVT

The inclusion of the Stone Plastic Composite (SPC) core is the defining factor in this floor's superior water resistance. Traditional Luxury Vinyl Tile (LVT) utilizes a flexible PVC core that, while water-resistant, still contains plasticizers that can contribute to minor dimensional changes when submerged over long periods. The SPC core, however, is a high-density, rigid composition of natural limestone powder and stabilizers. This composition results in virtually zero water absorption or swelling, which is critical for areas like commercial kitchens or bathrooms.

A technical Waterproof SPC flooring vs LVT core comparison highlights the SPC core's rigidity as its primary advantage against water damage, as demonstrated by the negligible water absorption rate compared to standard LVT.

| Core Material | Primary Composition | Water Absorption & Swelling (24h Immersion) | Dimensional Stability (Thermal) |

| Standard LVT (Flexible PVC) | PVC Resin & Plasticizers | Low (Can exhibit minor swelling) | Moderate (Prone to expansion/contraction) |

| SPC (Stone Plastic Composite) | Limestone Powder & Stabilizers | Negligible (True waterproof core) | Excellent (High resistance to movement) |

B. Surface and Installation Sealing

While the core is waterproof, the installation method affects topical moisture handling. The Peel and stick vinyl tile moisture tolerance handles common household spills exceptionally well due to the impermeable nature of the vinyl wear layer. However, the self-adhesive installation means joints are not chemically sealed, reinforcing the need for the core itself to be the primary barrier against standing water.

III. Thermal Stability: High and Low-Temperature Resilience

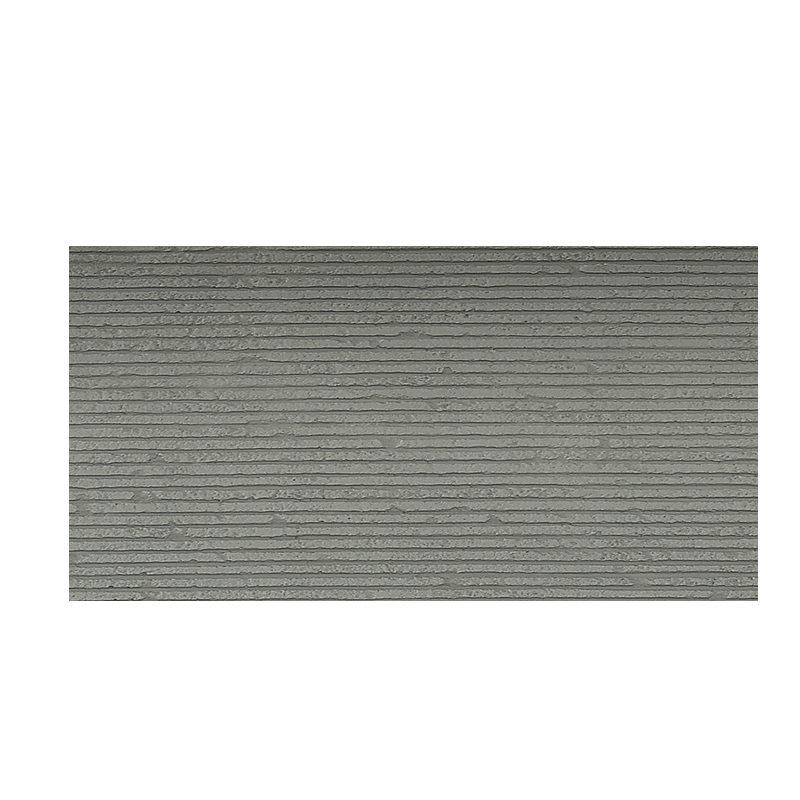

The primary B2B concern regarding composite flooring is dimensional stability: the ability of the plank to maintain its original size and shape when exposed to temperature extremes. Warping or gapping is caused by the material's coefficient of linear thermal expansion.

A. High-Temperature Performance and Heat Resistance

For installations in sun-exposed rooms or over subfloors featuring radiant heating, analyzing Self-adhesive LVT floor heat resistance specifications is mandatory. Standard LVT's high plasticizer content causes it to soften and expand significantly when exposed to temperatures exceeding 35°C to 40°C. The high mineral content in the SPC core drastically lowers the coefficient of thermal expansion, making the PVC LVT Self-Adhesive Stone Plastic Composite Floor exceptionally resistant to this heat-induced movement, ensuring joints remain tight.

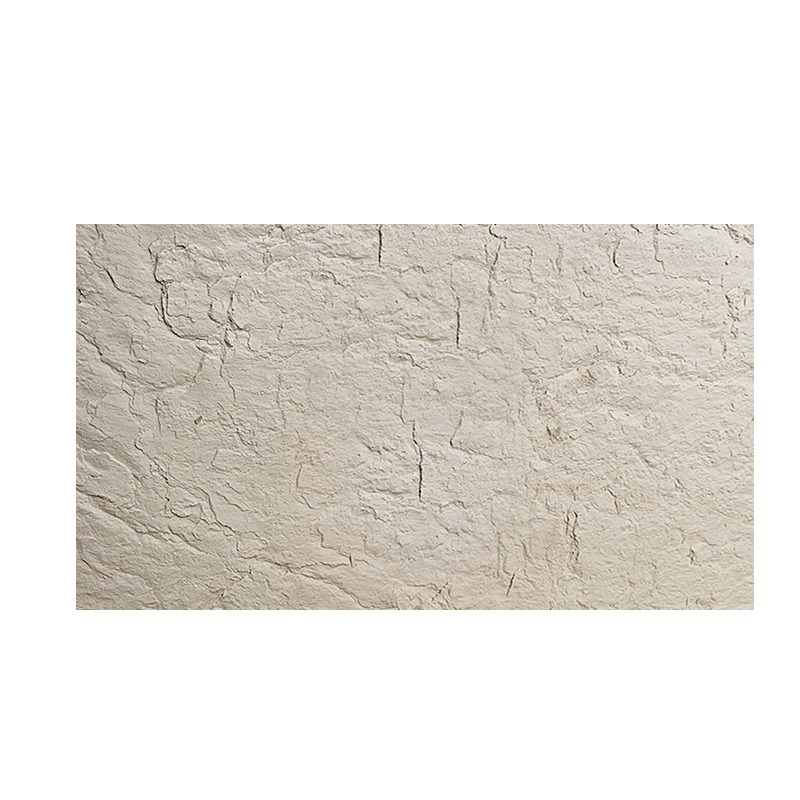

B. Cold Environment Integrity

Equally important is the Low temperature warping resistance SPC flooring. In unheated warehouses or areas subject to cold drafts, materials tend to contract. Flexible LVT can become brittle or shrink, potentially leading to gapping at the seams. The inherent rigidity of the SPC core provides superior resistance to contraction, maintaining dimensional stability even in temperatures approaching 0°C or lower. This makes the product viable for areas like four-season porches or cold storage facilities.

IV. Engineering for Long-Term Dimensional Stability

Dimensional stability is a quantifiable metric, crucial for large commercial projects where floor integrity over vast areas is required.

A. Measuring Stability: The Role of the SPC Core

The technical robustness of the PVC LVT Self-Adhesive Stone Plastic Composite Floor is confirmed through rigorous testing, adhering to standards like European Standard EN ISO 23999. This standard measures dimensional change under forced heat exposure. The high density and mineral content of the core are key factors in achieving superior results. The SPC core dimensional stability B2B analysis demonstrates that the plank will remain flat and true, minimizing the risk of edge curl or gapping.

B. The Adhesion Factor in Thermal Movement

While the SPC core provides rigidity, the quality of the self-adhesive backing must be engineered to withstand the minor thermal shifts that do occur. A high-quality adhesive maintains its shear strength across a wide temperature range, ensuring that the plank remains firmly anchored to the subfloor even as it attempts to subtly expand or contract, thus supplementing the Low temperature warping resistance SPC flooring capability.

V. Performance-Driven Composite Flooring

The PVC LVT Self-Adhesive Stone Plastic Composite Floor represents a major advancement, solving the common trade-off between installation ease and long-term structural integrity. Its SPC core provides absolute waterproof performance, verifiable via the Waterproof SPC flooring vs LVT core comparison, and exceptional thermal stability, confirmed by Self-adhesive LVT floor heat resistance specifications and SPC core dimensional stability B2B analysis. Haining Yunxi New Material Technology Co., Ltd., through continuous R&D, offers this robust flooring system, ensuring optimal performance for modern construction projects and meeting the high standards required by B2B partners who prioritize durability and reliability.

VI. Frequently Asked Questions (FAQ)

1. How does the SPC core prevent water damage compared to standard LVT?

The SPC core is composed mainly of limestone powder and stabilizers, making it rigid and virtually non-porous. This technical difference means the core itself has negligible water absorption or swelling, providing true waterproof integrity, as demonstrated in any Waterproof SPC flooring vs LVT core comparison.

2. Can this flooring be installed in unheated spaces like cottages or seasonal rooms?

Yes. The rigid SPC core provides high Low temperature warping resistance SPC flooring. Unlike flexible vinyl, the rigid structure resists contraction in cold temperatures, significantly reducing the risk of gapping or brittleness at the seams.

3. What temperature limitations should B2B installers be aware of for heat resistance?

While highly stable, installers should consult Self-adhesive LVT floor heat resistance specifications. Typically, due to the SPC core, this flooring can handle higher temperatures (often up to 60°C) than standard LVT, making it suitable for most radiant heating systems, provided the subfloor temperature is properly regulated.

4. Does the self-adhesive nature impact the floor's ability to handle topical moisture?

The Peel and stick vinyl tile moisture tolerance is excellent against topical spills because the surface wear layer is impermeable. However, the waterproof assurance comes from the non-absorbent SPC core, not the adhesive joints, emphasizing that the material itself provides the primary barrier.