+86-18367343973

- 1 The Science of Moisture Resistance: WPC vs. Traditional Materials

- 2 Combating Fungal Growth: The Mold-Resistant Advantage

- 3 Why Haining Yunxi is the Professional Choice

- 4 Frequently Asked Questions (FAQ)

- 4.1 1. Can wpc panels for interior walls be used directly in a shower enclosure?

- 4.2 2. Are eco friendly wpc wall panels for bathrooms safe for indoor air quality?

- 4.3 3. How do you handle easy to install wpc panels for basement renovation on damp walls?

- 4.4 4. Does the anti-corrosion wpc panels for kitchen walls finish fade over time?

- 4.5 5. Why is low maintenance wpc interior wall cladding better than tiles for high-humidity areas?

In the realm of modern architectural design, the durability of surface materials in challenging environments like bathrooms, kitchens, and basements is a primary concern for engineers and homeowners alike. The question of whether wpc panels for interior walls can truly withstand high-humidity conditions without degradation is more relevant than ever. Haining Yunxi New Material Technology Co., Ltd. has long been at the forefront of this technical challenge, focusing on the independent research and development of high-performance wood veneer wall panels and flooring. As an all-round modern enterprise, we integrate technological innovation and a rich product system to meet the rigorous demands of both luxury home decorations and large-scale construction projects.

The Science of Moisture Resistance: WPC vs. Traditional Materials

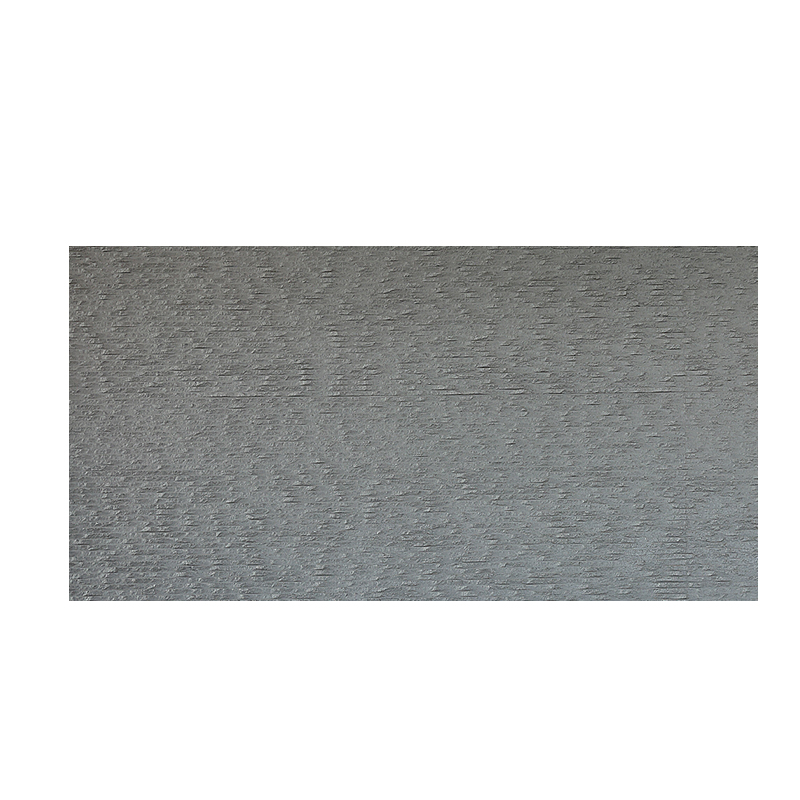

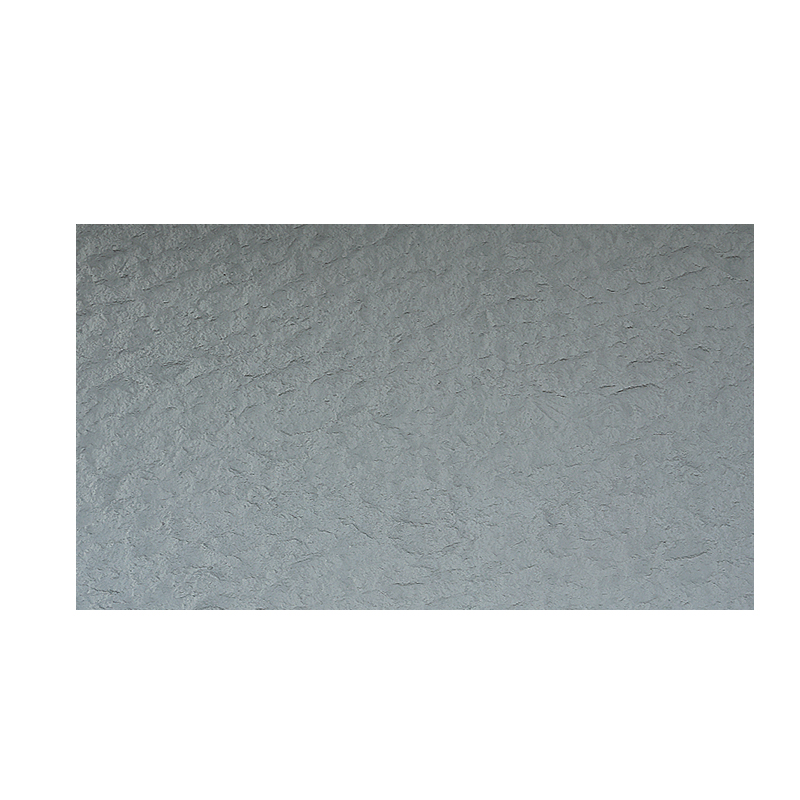

Wood-Plastic Composite (WPC) is engineered to solve the inherent flaws of natural timber—specifically its hygroscopic nature. Standard wood fibers absorb water, leading to swelling, warping, and eventually, rot. In contrast, wpc panels for interior walls are composed of a synergistic blend of recycled wood fibers and thermoplastics (typically HDPE or PVC). This composite structure encapsulates the organic fibers in a protective plastic matrix, drastically reducing water absorption rates.

According to the ASTM D570 water absorption tests conducted in late 2024, high-quality WPC materials demonstrate an absorption rate of less than 1.5% after 24 hours of submersion, whereas traditional plywood can exceed 25%. This technical breakthrough ensures that even in "splash zones," the panels maintain their dimensional stability. For B2B procurement, choosing eco friendly wpc wall panels for bathrooms provides a long-term solution that avoids the costly replacement cycles associated with moisture-damaged drywall or timber.

Source: ASTM D570 Water Absorption Standards for WPC Materials

Performance Comparison: Humidity and Dimensional Stability

In high-humidity areas, the atmospheric moisture can cause materials to expand. A low maintenance wpc interior wall cladding system is specifically designed to have a much lower thermal and moisture expansion coefficient than standard PVC or solid wood. While solid wood moves significantly with the seasons, WPC remains nearly inert, preventing the "buckling" effect often seen in poorly ventilated basements.

| Performance Metric | Traditional Natural Wood | Haining Yunxi WPC Panels |

| Water Absorption (24h) | 15% - 30% (High risk of rot) | < 1.5% (Waterproof surface) |

| Mold/Mildew Resistance | Poor; organic base attracts fungi | Excellent; non-porous thermoplastic barrier |

| Dimensional Stability | High expansion/contraction | Minimal movement (< 0.1% change) |

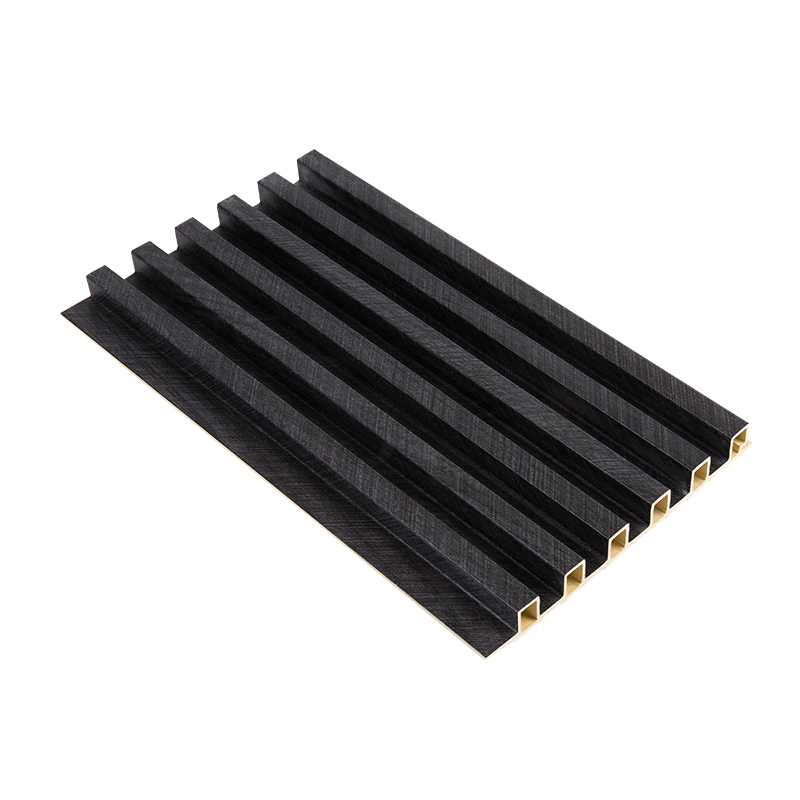

| Installation Speed | Slow; requires sanding/staining | Fast; tongue-and-groove "click" system |

Combating Fungal Growth: The Mold-Resistant Advantage

Mold and mildew thrive on organic matter (cellulose) combined with moisture. In traditional walls, paper-faced drywall and wood studs provide the perfect food source. Because wpc panels for interior walls utilize a plastic-encapsulation technology, the wood fibers are effectively "hidden" from fungal spores. Furthermore, the non-porous surface of anti-corrosion wpc panels for kitchen walls prevents mold from taking root in the substrate, even in the presence of steam and cooking grease.

Technological innovation in 2025 has seen the introduction of antimicrobial additives within the extrusion process. According to a 2025 market report by Grand View Research, the global demand for mold-resistant interior composites is projected to grow at a CAGR of 11.3%, driven by rising health awareness and stricter building codes in high-humidity regions. This makes durable wpc wall boards for high humidity areas not just an aesthetic choice, but a health-conscious engineering decision.

Source: WPC Market Analysis: Growth in Mold-Resistant Construction Materials

Comparison of Mold Resistance and Hygiene

When comparing easy to install wpc panels for basement renovation to traditional plaster or paint, the hygienic advantages are clear. Plaster is porous and can trap bacteria; WPC panels can be sanitized with standard cleaning agents without damaging the finish or compromising the structure.

| Environment Factor | Plaster / Drywall | WPC Interior Wall Systems |

| Surface Porosity | High (Traps moisture and spores) | Zero (Non-porous polymer finish) |

| Cleaning Method | Gentle dusting; avoids water | Washable with damp cloth/sanitizers |

| Lifespan in Basements | 5-7 years (due to dampness) | 20+ years (with zero degradation) |

Why Haining Yunxi is the Professional Choice

As a leading developer in the industry, Haining Yunxi New Material Technology Co., Ltd. has established a product system that balances beauty with uncompromising technical performance. Our panels are not only eco friendly wpc wall panels for bathrooms but also meet international safety and environmental standards. Our focus on technological innovation and team management has allowed us to develop anti-corrosion wpc panels for kitchen walls that resist the chemical stressors of modern cleaning and high-heat cooking environments.

- Independent R&D: Continuous innovation in wood veneer and WPC formulations.

- Rich Product System: Solutions for residential home decoration and commercial construction.

- Technological Innovation: Advanced extrusion lines ensuring consistent density and finish.

- Professional Support: Expert guidance for project-based procurement and installation.

Frequently Asked Questions (FAQ)

1. Can wpc panels for interior walls be used directly in a shower enclosure?

While wpc panels for interior walls are highly water-resistant and effectively waterproof on the surface, they are best suited for bathroom walls and ceilings rather than direct "wet-room" shower stalls unless specific waterproof sealing is applied to the joints and edges.

2. Are eco friendly wpc wall panels for bathrooms safe for indoor air quality?

Yes. High-quality WPC panels from Haining Yunxi New Material Technology Co., Ltd. are designed with low VOC emissions, often meeting E0 or E1 formaldehyde standards, making them safer for enclosed, humid spaces like bathrooms.

3. How do you handle easy to install wpc panels for basement renovation on damp walls?

For basements, it is recommended to install the panels on a light-gauge steel or aluminum furring strip system. This creates a "breathable" gap between the damp concrete wall and the durable wpc wall boards for high humidity, further preventing any moisture trap.

4. Does the anti-corrosion wpc panels for kitchen walls finish fade over time?

Our panels feature an advanced UV-protective layer. Unlike traditional paint or wood stain, the color is integrated into the material and the surface film, ensuring that the finish remains vibrant even when exposed to sunlight or frequent cleaning.

5. Why is low maintenance wpc interior wall cladding better than tiles for high-humidity areas?

While tiles are waterproof, the grout lines between tiles are porous and often become a breeding ground for mold. WPC panels use a seamless or tongue-and-groove system that eliminates these problematic grout lines, making maintenance significantly easier.