+86-18367343973

- 1 Introduction

- 2 What are UV Wall Boards?

- 3 Benefits of UV Wall Boards

- 4 Types and Styles of UV Wall Boards

- 5 Applications of UV Wall Boards

- 6 Installation Guide

- 7 Maintenance and Care

- 8 Cost Considerations

- 9 Where to Buy UV Wall Boards

- 10 Trends and Innovations in UV Wall Boards

- 11 Case Studies and Examples

- 12 Common Problems and Solutions

- 13 Conclusion

- 14 FAQ

Introduction

In the evolving world of interior architecture, the demand for materials that balance aesthetics with high-performance functionality has never been greater. UV Wall Boards have emerged as a frontrunner in this space, revolutionizing how we approach wall cladding in both residential and commercial environments.

Commonly known for their stunning high-gloss finishes and remarkable durability, these boards offer a sophisticated alternative to traditional materials like natural stone or solid wood. Whether you are a homeowner looking to refresh a kitchen, an interior designer seeking a versatile decorative element, or a contractor in need of a time-efficient installation solution, UV wall boards provide a compelling mix of style and substance.

The primary appeal lies in their ability to mimic premium textures—such as marble or rare wood grains—while offering superior resistance to moisture, scratches, and fading. This guide will explore everything you need to know about integrating this modern material into your next project.

What are UV Wall Boards?

Definition and Composition

A UV wall board is a decorative paneling material characterized by a surface treated with Ultraviolet (UV) curing technology. While the core of the board can vary, it typically consists of a sturdy base layer—often a PVC (Polyvinyl Chloride) or MDF (Medium-Density Fibreboard) substrate.

The "UV" in the name refers to the specialized coating process. During manufacturing, a protective lacquer is applied to the surface and then cured using intense ultraviolet light. This photochemical reaction hardens the coating instantly, creating a dense, non-porous, and crystal-clear protective shield.

The UV Coating Process: Advantages

The UV curing process is what sets these boards apart from standard painted or laminated panels. Key advantages include:

- Instant Hardening: The UV light bonds the coating to the substrate immediately, creating a surface that is significantly harder and more scratch-resistant than air-dried finishes.

- Enhanced Clarity: The coating enhances the depth of the printed pattern underneath, making marble veins look more realistic and colors appear more vibrant.

- Chemical Stability: Once cured, the surface becomes inert and highly resistant to household chemicals, acids, and alkalis.

Comparison with Traditional Wall Panels

When deciding between materials, it is helpful to see how UV wall boards stack up against traditional options:

| Feature | UV Wall Boards | Traditional PVC Panels | Natural Wood/Stone |

| Surface Hardness | Very High (UV Shielded) | Moderate | Varies (Stone is high) |

| Moisture Resistance | Excellent (Waterproof) | Good | Poor (Wood) to High (Stone) |

| Maintenance | Wipe clean; no sealing | Wipe clean | Requires oiling/sealing |

| Weight | Lightweight | Lightweight | Very Heavy |

| Cost | Mid-range | Budget-friendly | Premium/Expensive |

| Visual Depth | High Gloss / Deep Texture | Matte / Flat | Natural Variation |

Benefits of UV Wall Boards

Durability and Longevity

- Resistance to Scratches and Impacts: The UV-cured top layer acts as an armor. Unlike standard paint or wallpaper, it does not easily chip or scuff when bumped by furniture or vacuum cleaners.

- Wear Resistance: These boards maintain their "new" look for years, even in high-traffic areas like hallways or commercial lobbies.

- Long-term Cost Savings: While the initial investment may be higher than basic paint, the lack of need for repainting, resurfacing, or specialized repairs makes them a highly cost-effective solution over a 10-to-15-year lifecycle.

Aesthetic Appeal

- Visual Versatility: Thanks to high-definition printing technology, these boards can replicate the look of Calacatta marble, charred wood, or industrial concrete with startling realism.

- Modern and Sleek Appearance: The signature high-gloss finish provides a mirror-like reflection that can make small rooms feel larger and brighter. For those preferring a more understated look, matte and textured options are also available.

Easy Installation

- Lightweight Nature: Despite their stone-like appearance, they are significantly lighter than real rock or heavy timber, making them easier to transport and handle by a single person.

- Versatile Mounting: They can be applied directly over existing flat surfaces (like old tile or drywall) using high-strength construction adhesives. Many systems also feature interlocking tongue-and-groove designs that ensure a seamless, level fit without complex masonry tools.

Low Maintenance

- Effortless Cleaning: Because the surface is non-porous, dust and grime cannot penetrate the material. A simple wipe with a damp microfiber cloth is usually all that is required.

- Stain and Fade Resistance: The UV coating is chemically stable, meaning it won't yellow over time when exposed to sunlight, and common spills like coffee or juice won't leave permanent marks.

Hygiene and Health

- Antibacterial Properties: The smooth surface leaves no room for bacteria to hide or colonize.

- Mold and Mildew Resistance: Since the boards (especially PVC-based ones) do not absorb moisture, they are naturally resistant to fungal growth, making them perfect for humid bathrooms and basements.

Eco-Friendliness

- Recyclable Materials: Many UV wall boards are made from PVC and calcium carbonate composites that are 100% recyclable at the end of their life.

- Reduced Environmental Impact: By choosing a marble-patterned UV board over real marble, you are reducing the demand for intensive quarrying and the high carbon footprint associated with transporting heavy natural stone. Additionally, the UV curing process itself is VOC-free (Volatile Organic Compounds), meaning it doesn't release harmful gasses during production or after installation.

Types and Styles of UV Wall Boards

By Material (Substrate)

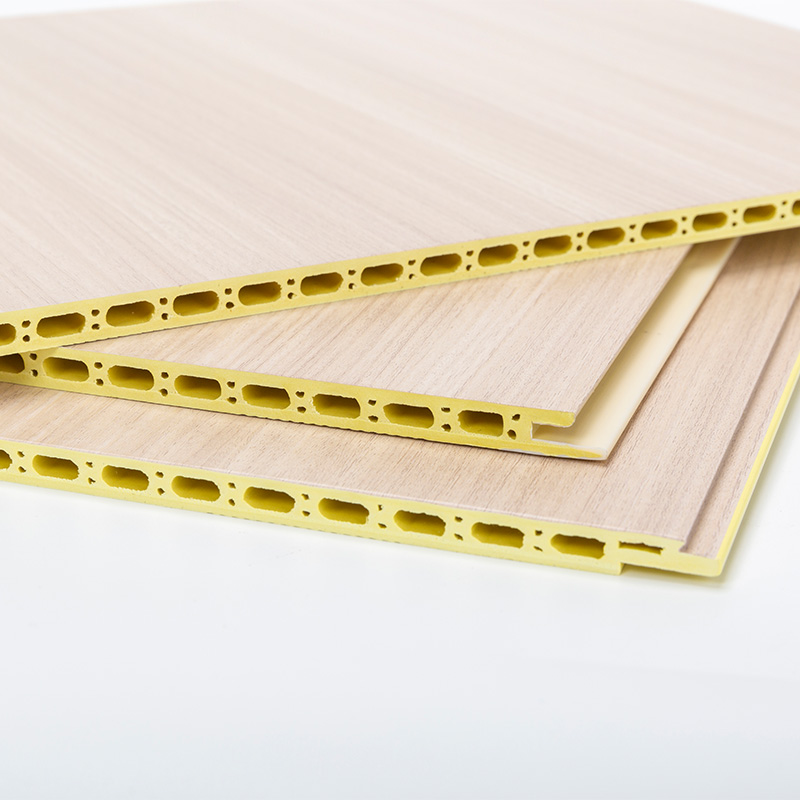

- PVC UV Wall Boards (Stone-Plastic Composite):

- Composition: A blend of polyvinyl chloride and natural stone powder (calcium carbonate).

- Best for: Wet areas like bathrooms and kitchens. It is 100% waterproof and highly fire-retardant.

- Characteristics: Rigid, durable, and highly resistant to expansion or contraction.

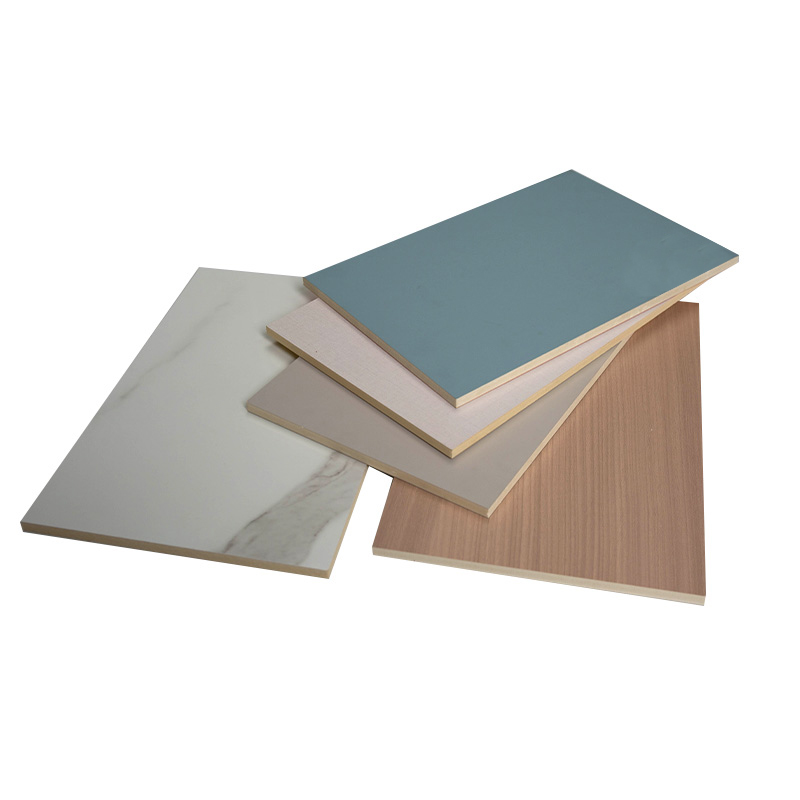

- MDF UV Wall Boards:

- Composition: Medium-Density Fibreboard made from wood fibers and resin.

- Best for: Dry areas such as bedrooms, living rooms, and office feature walls.

- Characteristics: Offers a smoother surface for high-gloss finishes but is susceptible to moisture damage if not sealed correctly.

- Other Composite Materials: Some boards use WPC (Wood Plastic Composite) or Fiber Cement cores, balancing the natural feel of wood with the durability of plastic or the fire resistance of mineral bases.

By Finish

- High Gloss: The most popular choice. It features a mirror-like sheen that reflects light, making spaces appear brighter and more luxurious.

- Matte: A soft, non-reflective finish that hides fingerprints and smudges better than gloss. It provides a contemporary, sophisticated look.

- Textured: These boards have a tactile surface (e.g., raised wood grain or stone pits) that adds physical depth and a more authentic feel to the design.

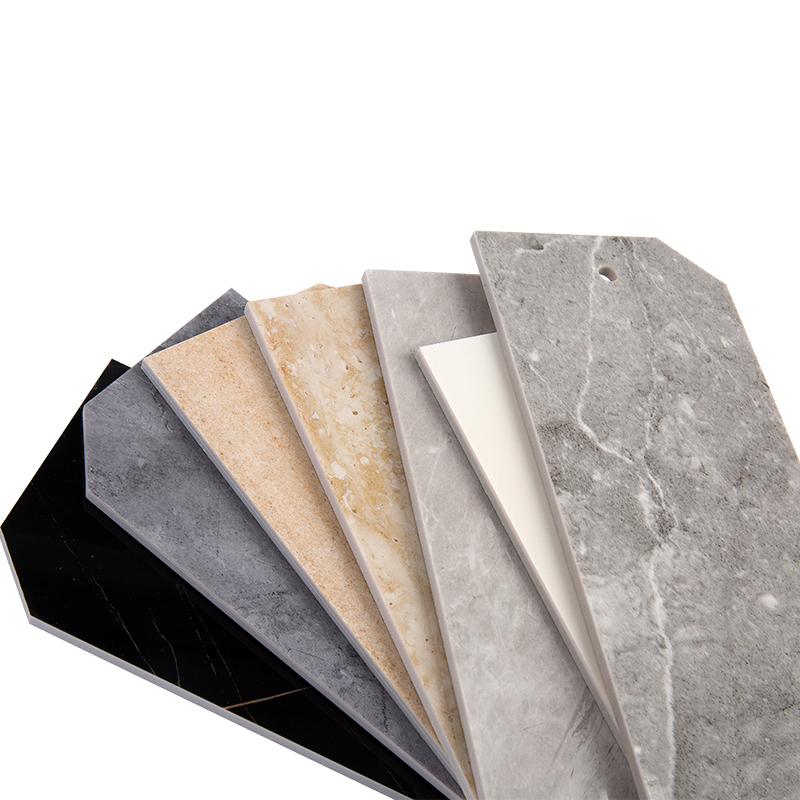

By Pattern/Design

- Marble & Stone: Replicates premium stones like Carrara, Nero Marquina, or Travertine. This is the "gold standard" for luxury bathroom and lobby designs.

- Wood Grain: Offers the warmth of oak, walnut, or teak without the risk of warping, rotting, or termite damage.

- Solid Colors: Available in everything from minimalist whites and greys to bold, vibrant accent colors for modern branding or "pop" walls.

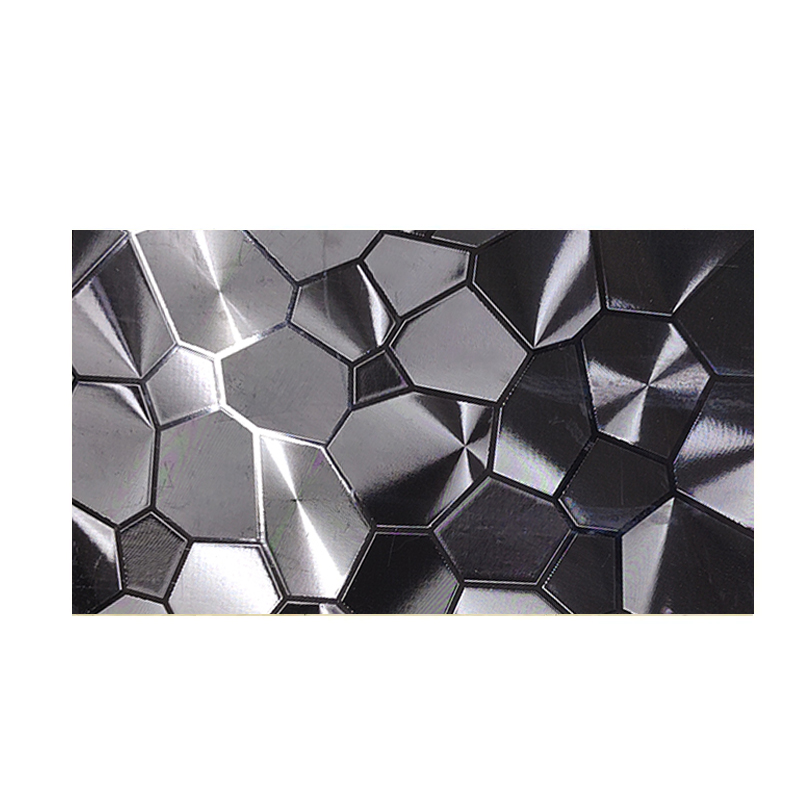

- Abstract & Metallic Designs: Includes geometric patterns, 3D effects, or brushed metal looks for avant-garde or industrial interior styles.

Applications of UV Wall Boards

Residential

- Living Rooms: Used as "TV Backdrop" walls or full-room cladding to create an upscale atmosphere.

- Bedrooms: Often used for headboard feature walls or integrated wardrobe surfacing.

- Bathrooms: A popular alternative to tiles because there are no grout lines to clean, and the panels are entirely waterproof.

- Kitchens: Used as backsplashes (away from direct high-heat sources) or for island cabinet cladding.

Commercial

- Offices: Ideal for reception desks, conference room feature walls, and sleek corridor cladding.

- Retail Stores: Provides a high-end backdrop for merchandise that is easy to update and resistant to customer wear and tear.

- Restaurants & Hotels: Used in lobbies, dining areas, and guest rooms to provide a luxury feel that meets commercial durability standards.

Specialized Settings

- Hospitals & Clinics: The antibacterial properties and ease of sterilization make them perfect for sterile environments.

- Schools: Durable enough to withstand the daily impact and cleaning requirements of high-traffic hallways and classrooms.

Installation Guide

Tools and Materials

- Cutting Tools: A circular saw with a fine-tooth blade or a table saw for straight cuts; a jigsaw for outlets and curves.

- Measuring & Marking: Measuring tape, a laser level (highly recommended), and a pencil.

- Adhesives: High-quality structural adhesive (neutral silicone or polyurethane-based) and a caulking gun.

- Safety Gear: Dust mask, safety goggles, and gloves.

- Finishing: Decorative trim (H-joints, corner profiles) or color-matched sealant.

Step-by-Step Installation

- 1. Surface Preparation: Ensure the wall is dry, flat, and free of dust or grease. If the wall is uneven, you may need to install a wooden or metal light-gauge steel frame (battening) first.

- 2. Measuring and Cutting: Measure the wall height and width carefully. Mark the back of the UV board and cut it to size. Pro tip: Cut with the decorative side facing up to prevent chipping the UV layer.

- 3. Applying Adhesive: Apply the adhesive to the back of the board in a "snake" pattern or in dots spaced about 10-15cm apart.

- 4. Board Placement: Press firmly against the wall. Use a level to ensure it is perfectly vertical. If using an interlocking system, slide the tongue of the next board into the groove of the previous one.

- 5. Sealing and Finishing: Install aluminum or PVC trims for internal/external corners and top edges. Use a color-matched sealant for any visible joints to ensure a waterproof finish.

Tips for a Professional Finish

- Ensuring proper alignment: Always start from the most visible corner of the room and work outward.

- Hiding seams and edges: Leave a tiny expansion gap (1-2mm) at the ceiling and floor, which will be covered by molding or baseboards.

Maintenance and Care

Cleaning

- Recommended cleaning products: Use a soft microfiber cloth and a mixture of water and mild dish soap.

- Do's and don'ts for cleaning UV wall boards:

- Do: Wipe in a circular motion to maintain the gloss; dry the surface with a clean cloth to prevent water spots.

- Don't: Never use scouring pads, steel wool, or abrasive "magic erasers," as these can create micro-scratches that dull the UV shine over time.

Preventative Measures

- Avoiding harsh chemicals and abrasive materials: Avoid using cleaners containing high concentrations of bleach, ammonia, or acetone.

- Protecting against physical damage: While fire-retardant, UV boards should not be in direct contact with open flames or high-heat appliances (like being placed directly behind a gas stovetop without a heat shield). Avoid dragging sharp metal objects against the surface.

Repairing Minor Damage

- Fixing scratches and small dents: For very light surface scratches, a high-quality automotive polish or wax can often restore the shine. Deep impacts are difficult to "pop out" because of the rigid core. In such cases, the damaged panel is usually replaced. Because of the adhesive installation, a single panel can be carefully removed and swapped without tearing down the entire wall.

Cost Considerations

Factors Affecting the Cost

- Material and finish: PVC-based boards are generally more affordable than MDF or WPC (Wood-Plastic Composite) hybrids. Additionally, specialized finishes like 3D textures or ultra-high-gloss coatings will carry a premium over standard flat patterns.

- Size and quantity: Boards typically range from 3mm to 12mm. Thicker panels (9–12mm) provide better sound insulation and structural rigidity but cost more in both raw materials and shipping. Standard size is 1220mm x 2440mm.

- Installation costs: If you are not DIY-ing, labor can account for 30% to 50% of the total project cost, depending on your region and the complexity of the wall.

Comparison with Other Wall Covering Options

| Option | Upfront Cost | Durability | Lifespan | Total Value |

| Paint | Lowest | Low (chips/fades) | 3–5 Years | Frequent maintenance needed |

| Wallpaper | Moderate | Moderate (peels) | 5–10 Years | High variety, fragile surface |

| UV Wall Boards | Mid-Range | High (impact resistant) | 10–15+ Years | Best long-term ROI |

| Traditional panels | High | High | 25+ Years | Requires sealing & heavy labor |

Budgeting Tips

- Planning and prioritizing: If your walls are flat and the room is square, a DIY installation can save hundreds of dollars. However, for "wet zones" (showers) or complex commercial spaces, a professional ensures the waterproofing and seams are perfect.

- DIY vs. professional installation: Always order 10% more material than your square footage calculation to account for cutting errors and pattern matching. Don't forget to budget for adhesives, corner trims, and specialized saw blades, which can add $50–$150 to a standard room project.

Where to Buy UV Wall Boards

Online Retailers

- List of reputable online stores: Ideal for browsing a massive catalog of patterns from the comfort of your home. Many offer sample swatches for a small fee, which is highly recommended to check color accuracy under your home's lighting.

Local Suppliers

- Finding local distributors and showrooms: Visiting a local distributor allows you to feel the weight and texture of the boards. It also saves significantly on shipping costs for heavy or oversized panels.

Factors to Consider When Choosing a Supplier Such As: yunxipvcboard.com

- Price and quality: Ensure the boards meet fire safety (e.g., Class B1) and environmental standards (e.g., E1 or VOC-free). Ask if the stated thickness is for the entire board or just the core.

- Variety and availability: Confirm they have the specific patterns in stock to avoid project delays.

- Customer reviews and reputation: UV boards are prone to corner damage during transit. Ensure the supplier uses protective wooden crates or heavy-duty edge protectors. If you need multiple boards for one large wall, confirm they are from the same production batch to avoid slight color variations.

Trends and Innovations in UV Wall Boards

New Designs and Patterns

- Emerging trends in colors and textures: Interior design in 2026 is moving toward "Nature-Embedded Textures" and "Warm Minimalism." New UV boards feature hyper-realistic textures of moss, bamboo, and raw clay. Brushed copper, champagne gold, and iridescent finishes are also trending.

Technological Advancements

- Improved UV coating techniques: Advancements in CNC routing allow for UV boards with physical 3D depth and geometric relief.

- Smart and interactive wall boards: Emerging "Smart Coating" technology integrates ultra-thin sensors into the UV layer, allowing the wall itself to act as a touch-sensitive switch for lighting or temperature control.

Sustainable Options

- Eco-friendly materials and manufacturing processes: Manufacturers are shifting away from virgin plastics toward MGO (Magnesium Oxide) and recycled WPC cores. Cutting-edge research has introduced photosynthetic coatings that can capture CO2 from the indoor air.

Case Studies and Examples

- Showcase successful projects using UV wall boards:

- Residential (The Waterfront Condo): A 50-unit high-rise renovation in a humid coastal climate. Full bathroom and kitchen backsplash cladding using Marble-patterned PVC UV boards. After two years, panels showed zero signs of peeling or fading.

- Commercial (The Quick-Service Restaurant): A national restaurant chain using high-gloss, wood-grain UV boards for dining area wainscoting. The non-porous surface allowed staff to sanitize walls daily without damaging the finish, dropping maintenance costs by 75%.

- Highlight the versatility and impact: These examples demonstrate how UV boards perform in extreme humidity and high-traffic commercial environments.

Common Problems and Solutions

- Addressing issues like:

- Bubbling or Peeling: Often caused by trapped moisture or low-quality adhesive. Solution: Ensure the wall is 100% dry before install; use a neutral-cure structural adhesive.

- Color Fading: Historically an issue, but mitigated by modern UV resins. Solution: Ensure the product has an enhanced UV-stable topcoat for sun-drenched rooms.

- Joint Visibility: Caused by uneven walls. Solution: Use a laser level during setup; hide seams with aluminum H-profiles or color-matched sealant.

- Troubleshooting tips and solutions: Only use microfiber cloths and mild soap; apply a specialized UV-safe wax to buff out light marks.

Conclusion

- Recap of the benefits and versatility: UV wall boards represent the perfect marriage of luxury and logic. They provide the high-end look of marble and wood with the durability of modern industrial materials.

- Encourage readers to consider UV wall boards: Whether for a residential refresh or a commercial fit-out, they offer a time-efficient and cost-effective solution.

- Final thoughts on the future: As technology continues to integrate "smart" and "green" features into these panels, they are set to remain a staple of modern interior design for years to come.

FAQ

- Q: Can UV wall boards be used outdoors?

- A: Most are designed for interior use. While the UV coating is sun-resistant, the substrate may not handle extreme temperature swings unless specifically rated for "Exterior Use."

- Q: Are they fireproof?

- A: Most PVC-based and MGO-based UV boards are rated Class B1 (Fire Retardant), meaning they are difficult to ignite and self-extinguish.

- Q: Can I install them over old tiles?

- A: Yes! As long as the tiles are firmly attached and cleaned of any soap scum, you can apply UV boards directly over them using a high-strength adhesive.