+86-18367343973

- 1 What are UV PVC Panels?

- 2 Brief Explanation of Polyvinyl Chloride (PVC)

- 3 What Makes Them UV Resistant?

- 4 Why Choose UV PVC Panels?

- 5 Benefits of Using UV PVC Panels

- 6 Applications of UV PVC Panels

- 7 Types of UV PVC Panels

- 8 Installation Guide for UV PVC Panels

- 9 Maintenance and Care

- 10 Where to Buy UV PVC Panels

- 11 Common Problems and Solutions

- 12 UV PVC Panels vs. Alternatives

- 13 Future Trends in UV PVC Panels

- 14 Conclusion

- 15 Technical Specifications and Quality Standards

What are UV PVC Panels?

UV PVC panels are advanced decorative and functional wall cladding solutions engineered for high performance in demanding environments. These panels consist of a high-density polyvinyl chloride base that is treated with a specialized ultraviolet (UV) curing process. This process involves applying a high-grade lacquer or protective film to the surface and instantly hardening it under intense ultraviolet light. The result is a non-porous, stone-hard finish that creates a brilliant gloss or sophisticated texture while protecting the underlying design.

Brief Explanation of Polyvinyl Chloride (PVC)

Polyvinyl Chloride, commonly known as PVC, is one of the world's most versatile and widely used synthetic polymers. It is inherently lightweight, flame-retardant, and resistant to chemicals and moisture. In the context of premium wall paneling, PVC acts as the ideal substrate because it does not warp like wood or corrode like metal. Haining Yunxi New Material Technology Co., Ltd. has long been focusing on the independent research and development and production of wood veneer wall panels and flooring, utilizing the inherent strengths of PVC to build a rich product system that sets a high standard in the industry.

What Makes Them UV Resistant?

Standard PVC can become brittle or yellow when exposed to light over time. However, UV PVC panels are specifically engineered with UV inhibitors integrated into the substrate and a protective UV-cured topcoat. This "shield" reflects harmful radiation and prevents the photochemical degradation that typically affects lesser materials. Because of this specialized manufacturing, the panels maintain their structural integrity and color vibrancy even in spaces with significant light exposure.

Why Choose UV PVC Panels?

Choosing UV PVC panels is an investment in both aesthetics and longevity. They offer the luxurious look of marble, grain, or solid stone at a fraction of the cost and weight. As an all-round development of modern enterprise, Haining Yunxi New Material Technology Co., Ltd. has seen rapid growth in technological innovation and brand building. This expertise ensures that the panels not only meet the diverse needs of modern home decoration—from minimalist to classical styles—but also satisfy the rigorous demands of large-scale construction projects. Their ability to blend beauty with rugged durability is why they are increasingly favored by consumers and industry professionals alike.

Benefits of Using UV PVC Panels

The rise in popularity of UV PVC panels is driven by their exceptional performance characteristics, which often surpass those of traditional cladding materials. Haining Yunxi New Material Technology Co., Ltd. leverages its deep industry experience to ensure every panel provides a balanced mix of functional and decorative advantages.

Durability and Longevity

One of the primary reasons for the industry-wide adoption of these panels is their extreme durability. The surface is hardened through a specialized photochemical reaction, creating a shield that is significantly more resistant to wear than traditional paint or laminates. These panels are built to last for decades without showing signs of aging, making them a cornerstone of the rich product system developed by Haining Yunxi New Material Technology Co., Ltd.

Resistance to UV Radiation

Unlike standard plastics that may degrade or lose their color when exposed to light, UV PVC panels are engineered for stability. Key features include:

- Color Retention: The protective coating prevents the high-definition print layer from fading.

- Structural Integrity: UV inhibitors prevent the PVC core from becoming brittle, ensuring the panel remains flexible yet strong.

Water Resistance

Because PVC is inherently non-porous, these panels are 100% waterproof. This makes them ideal for environments where moisture is a constant factor. They do not swell, rot, or harbor mold, providing a hygienic and long-lasting alternative to wood-based products.

Low Maintenance

The high-gloss or smooth matte finish of UV PVC panels ensures that dirt, grease, and stains cannot penetrate the surface. Maintenance is remarkably simple:

- Easy Cleaning: Most surfaces can be restored to their original luster with a simple wipe using a damp cloth.

- No Specialized Treatments: Unlike natural stone or wood, these panels never require sanding, sealing, or varnishing.

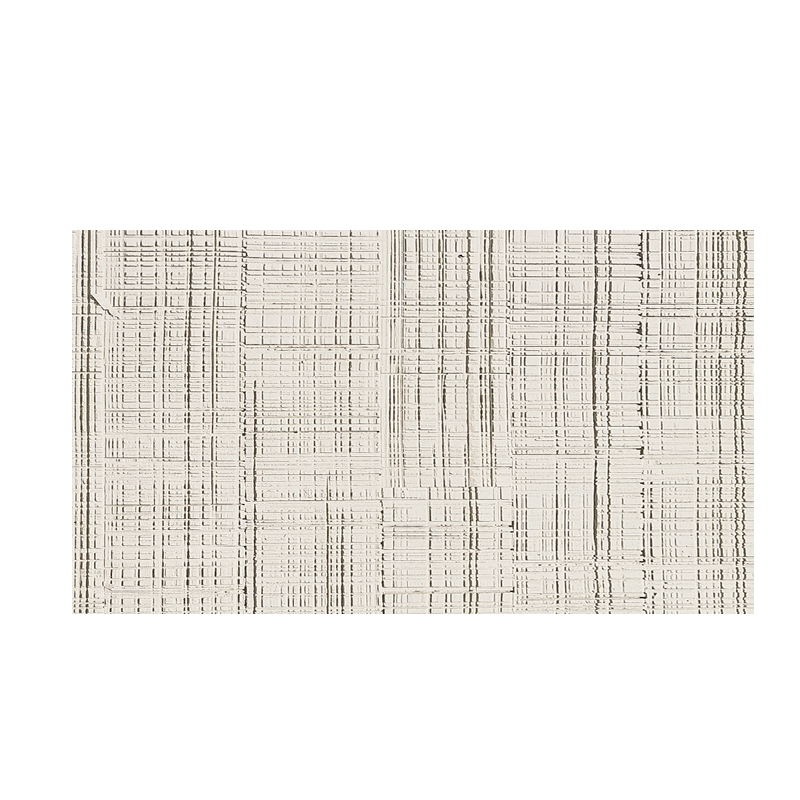

Aesthetic Appeal and Design Flexibility

Modern printing and curing technology allow for an almost infinite variety of designs. Whether the project requires a classic marble look, a modern wood veneer, or a bold solid color, the design flexibility meets the needs of various styles of home decoration. This versatility is a result of continuous technological innovation, allowing designers to achieve luxury aesthetics without the premium price tag of natural materials.

Cost-Effectiveness

UV PVC panels provide significant savings across their entire lifecycle:

- Lower Material Costs: They are much more affordable than natural marble or solid timber.

- Reduced Installation Labor: Their lightweight nature and ease of handling mean projects are completed faster, saving on contractor fees.

- Minimal Upkeep: The lack of recurring maintenance costs further enhances their value over time.

Applications of UV PVC Panels

The versatility of UV PVC panels makes them an essential material across a wide spectrum of environments. From high-end residential renovations to heavy-duty industrial builds, the product systems developed by Haining Yunxi New Material Technology Co., Ltd. are designed to perform wherever durability and style are required.

Interior Wall Coverings

UV PVC panels serve as a stunning decorative solution for interior spaces. They are frequently used to create "feature walls" in living rooms or as sophisticated cladding in hallways. Because they can mimic the high-end look of wood veneer or natural stone, they are highly favored by consumers looking to achieve a premium aesthetic in home decoration.

Exterior Cladding

Specially formulated UV PVC panels are increasingly used for exterior applications. Their enhanced UV resistance ensures that the building's facade remains vibrant and protected against the elements. This application showcases the technological innovation of modern enterprises in creating weather-resistant materials that do not sacrifice visual appeal.

Ceilings

Due to their lightweight nature, these panels are an excellent choice for ceiling installations. They provide a clean, modern finish that is easy to install overhead and requires zero painting. They are particularly effective in concealing wiring and plumbing while offering a fire-retardant surface.

Bathroom and Shower Walls

In wet areas, UV PVC panels outshine traditional tiles. Their 100% waterproof nature and lack of grout lines make them the perfect solution for:

- Shower Enclosures: Total moisture protection with no risk of leaks through the material.

- Vanity Backsplashes: Easy to clean and resistant to soap scum and water spots.

- Complete Bathroom Lining: Creates a seamless, spa-like environment that stays mold-free.

Cleanrooms and Healthcare Facilities

Hygiene is paramount in medical settings. UV PVC panels are widely used in hospitals, clinics, and laboratories because:

- Antibacterial Properties: The non-porous surface prevents the growth of bacteria and fungi.

- Chemical Resistance: They can withstand frequent sanitization with strong medical-grade cleaning agents without degrading.

Agricultural Buildings

The rugged durability of these panels makes them ideal for the agricultural sector. They are commonly installed in dairies, poultry farms, and storage facilities. In these environments, the panels provide a resilient surface that is easy to pressure-wash and resistant to the corrosive effects of animal waste and humidity, meeting the rigorous needs of various types of construction projects.

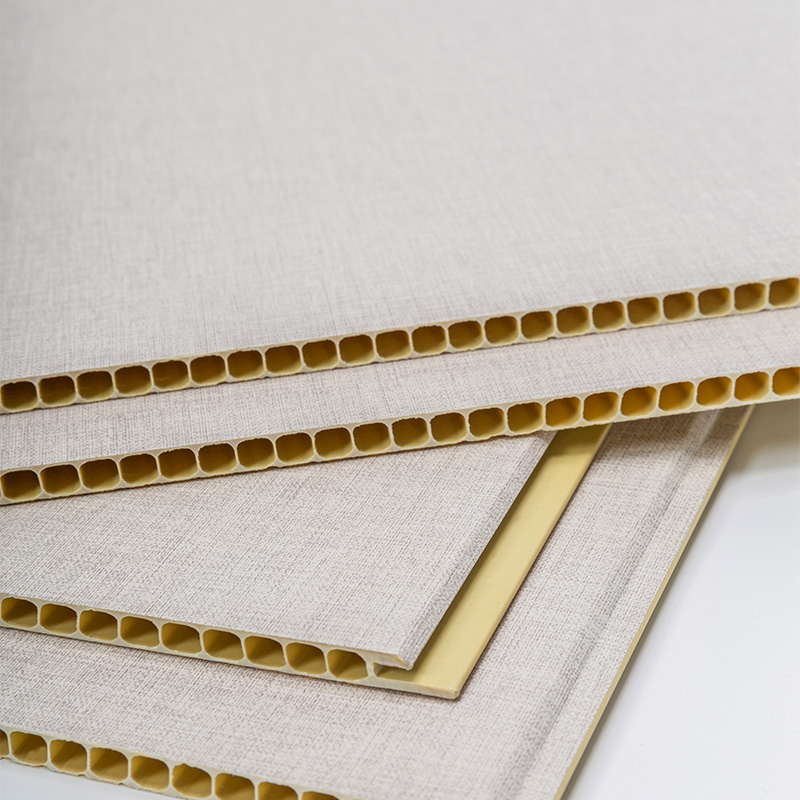

Types of UV PVC Panels

Understanding the different construction methods of UV PVC panels is essential for selecting the right product for your specific environment. Haining Yunxi New Material Technology Co., Ltd. has developed a diverse range of substrates to ensure their product system can meet both the structural and aesthetic requirements of any project.

Solid PVC Panels

Solid UV PVC panels are known for their high density and exceptional impact resistance. These are typically the "standard" for high-traffic areas. Characteristics include:

- Rigidity: A solid core that provides a firm feel similar to natural stone.

- Durability: Excellent resistance to dents and structural damage, making them a top choice for commercial construction projects.

- Waterproofing: Being 100% solid PVC, there is no chance of moisture absorption from any angle.

Foam PVC Panels

Often referred to as expanded PVC or PVC foam boards, these panels incorporate a cellular structure. While the surface remains hard and UV-cured, the core is lighter. Advantages include:

- Lightweight: Much easier to handle for ceiling installations or large-scale wall cladding.

- Insulation: The foam core provides better thermal and acoustic insulation than solid panels.

- Ease of Fabrication: Highly favored by contractors for projects requiring complex on-site cutting and shaping.

Multi-layered PVC Panels

As a result of technological innovation, multi-layered or composite panels offer the best of both worlds. These typically consist of a core layer for stability, a printed design layer, and the final UV-cured protective coating. This structure allows for:

- Enhanced Stability: Reduced expansion and contraction in fluctuating temperatures.

- Visual Depth: Layers can be optimized to create a more realistic 3D effect in wood and stone patterns.

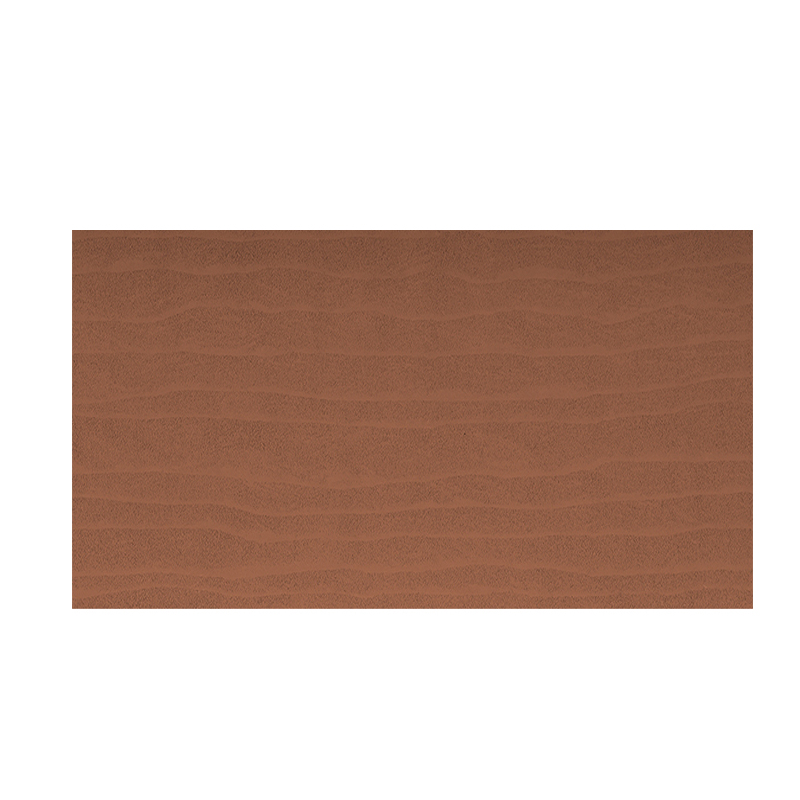

Different Finishes and Textures

To meet the needs of various styles of home decoration, UV PVC panels are available in several surface treatments:

High Gloss Finish

The most iconic finish, offering a mirror-like shine that reflects light and creates an upscale, luxurious atmosphere in lobbies and bathrooms.

Matte Finish

A sophisticated, non-reflective surface that is increasingly popular in modern minimalist home decoration. It is particularly effective at hiding fingerprints and smudges.

Textured and Embossed

Through advanced manufacturing processes, Haining Yunxi New Material Technology Co., Ltd. produces panels with physical textures, such as 3D wood grains or stone-pitted surfaces. This tactile quality adds a layer of realism that makes the panels indistinguishable from natural materials.

Installation Guide for UV PVC Panels

The efficiency of the installation process is one of the key reasons why UV PVC panels are preferred in modern construction. By following a systematic approach, both professional contractors and DIY enthusiasts can achieve a seamless finish that enhances the value of any property. Haining Yunxi New Material Technology Co., Ltd. continues to drive technological innovation in panel design, ensuring their products remain easy to handle and install across various types of construction projects.

Tools and Materials Required

To ensure a professional-grade installation, it is important to have the correct tools ready before beginning the project:

- Cutting Tools: A fine-tooth circular saw or a table saw for straight edges; a jigsaw for cutting out electrical outlets.

- Measurement: Measuring tape, a pencil for marking, and a laser level to ensure perfect alignment.

- Installation Hardware: High-strength neutral silicone adhesive or specialized construction glue; stainless steel screws if mechanical fastening is required.

- Safety Gear: Protective goggles, a dust mask, and gloves to ensure safety during the cutting process.

Surface Preparation

A successful installation begins with a clean and stable substrate. The wall surface must be dry, flat, and free of loose debris or oil. If the existing wall is significantly uneven, Haining Yunxi New Material Technology Co., Ltd. recommends installing a light-gauge steel or wooden battening system first. This provides a perfectly level plane for the panels and allows for necessary air circulation behind the cladding.

Cutting and Measuring Panels

Accuracy during the measurement phase reduces waste and ensures the patterns align correctly. When cutting UV PVC panels:

- Measurement: Always measure twice and mark the back of the panel to avoid scuffing the decorative UV surface.

- Cutting Technique: Cut with the decorative side facing up to prevent the UV coating from chipping at the edges. A fine-tooth blade will provide the cleanest finish.

Adhesive or Mechanical Fastening

Depending on the specific needs of various construction projects, panels can be secured using two primary methods:

Adhesive Method

This is the most common method for home decoration. Apply a high-quality adhesive in a "snake" or "grid" pattern to the back of the panel. Press the panel firmly against the wall, using a level to verify it is plumb. This method creates a clean look without visible fasteners.

Mechanical Fastening

In high-traffic commercial environments or for exterior cladding, mechanical fasteners or interlocking clips provide additional security. This ensures the panels remain stable even under significant temperature fluctuations or physical impact.

Sealing and Finishing

The final step involves the use of specialized trim and sealants to create a polished appearance. Use aluminum or color-matched PVC edge trims for internal and external corners. For wet areas like bathrooms, apply a bead of waterproof silicone sealant in the joints to ensure a 100% moisture-proof barrier. This attention to detail is what allows the rich product system of Haining Yunxi New Material Technology Co., Ltd. to shine in any environment.

Maintenance and Care

The high-performance UV-cured surface of UV PVC panels makes them one of the easiest wall cladding materials to maintain. To preserve the vibrant aesthetics and structural integrity of the rich product system from Haining Yunxi New Material Technology Co., Ltd., following a few simple care procedures will ensure the panels look new for decades. As an all-round development modern enterprise, the brand’s focus on technological innovation has resulted in surfaces that naturally repel stains and resist environmental wear.

Cleaning Procedures

Regular cleaning is the most effective way to maintain the brilliant gloss or sophisticated matte finish of your panels. The non-porous nature of the UV coating prevents dirt from becoming embedded.

- Routine Dusting: Use a soft microfiber cloth or a feather duster to remove surface dust on a weekly basis.

- Washing: For areas like kitchens or bathrooms, use a mixture of warm water and a mild, pH-neutral dish soap. Wipe the surface with a soft sponge or cloth.

- Drying: Always dry the panels with a clean, soft towel after washing to prevent water spots or streaks, especially on high-gloss finishes.

Preventing Damage

While UV PVC panels are engineered for high durability in various construction projects, certain precautions should be taken to avoid compromising the protective UV layer:

- Avoid Abrasives: Never use steel wool, scouring pads, or abrasive powders, as these can create micro-scratches that dull the UV shine over time.

- Chemical Caution: Avoid harsh chemicals such as undiluted bleach, acetone, or strong solvents. These can cause chemical etching on the surface coating.

- Heat Management: Although the panels are flame-retardant, they should not be exposed to direct, prolonged high heat (such as an open flame or high-wattage heat lamps) without a proper thermal shield.

Extending the Lifespan of Panels

To maximize the long-term value of your investment and ensure they continue to meet the needs of your home decoration style, consider these professional tips:

- Sealant Inspection: In wet environments like showers, check the silicone sealant in the corners and joints once a year. If the sealant shows signs of wear, re-applying it will maintain the waterproof integrity.

- Sunlight Exposure: While the panels are UV resistant, extremely intense and direct sunlight over many years can be mitigated by using curtains or UV-filtering window films, further preserving the deep color of the wood veneer or marble patterns.

- Prompt Spill Removal: While the panels are stain-resistant, removing splashes of oils or highly pigmented liquids (like red wine or ink) promptly will prevent any potential surface residue.

Where to Buy UV PVC Panels

Selecting the right source for your materials is just as critical as the installation itself. With the rapid pace of development in the industry, Haining Yunxi New Material Technology Co., Ltd. has established itself as a modern enterprise that consumers can trust. Their long-term focus on independent research and development ensures that whether you are sourcing for a small home renovation or a large-scale construction project, you are receiving a product backed by professional expertise.

Online Retailers

In the digital age, purchasing UV PVC panels online has become a convenient option for many homeowners and designers. Online platforms allow you to:

- Browse Extensive Catalogs: View the entire rich product system, from classic wood veneers to modern marble textures, all in one place.

- Compare Specifications: Easily check technical data such as panel thickness, UV coating density, and fire ratings.

- Read Expert Advice: Access digital guides and customer feedback to understand how specific panels perform in various styles of home decoration.

Local Suppliers

For large construction projects, partnering with local distributors or showrooms can offer distinct logistical advantages:

- Physical Inspection: Visit a showroom to feel the texture and verify the color accuracy of the panels under natural light.

- Immediate Availability: Local suppliers often stock popular designs, reducing the lead time for urgent projects.

- Expert Consultation: Engage with professionals who understand the local building codes and can recommend specific panels from the Haining Yunxi New Material Technology Co., Ltd. range to suit your regional climate.

Factors to Consider When Purchasing

To ensure you receive high-quality panels that will stand the test of time, keep the following factors in mind during your search:

Material Quality and Certification

Always verify that the panels meet international safety and environmental standards. Look for certifications regarding flame retardancy (such as Class B1) and low VOC emissions. A reputable enterprise like Haining Yunxi New Material Technology Co., Ltd. prioritizes technological innovation to ensure their materials are safe for residential use.

Brand Reputation and Research Capability

Consider the manufacturer's history. Companies that focus on independent R&D are more likely to offer panels with superior UV resistance and better structural stability. A brand that is "loved and favored by consumers" typically indicates a history of reliable performance and quality control.

Packaging and Shipping Logistics

UV PVC panels have a delicate high-gloss surface that must be protected during transit. Ensure your supplier uses robust packaging, such as protective films and reinforced edge guards, to prevent scratches or corner damage before the panels reach your site.

Common Problems and Solutions

Even with high-quality materials like the rich product system from Haining Yunxi New Material Technology Co., Ltd., improper installation or extreme environmental factors can occasionally lead to issues. Understanding how to troubleshoot these common problems ensures that your investment remains in top condition for various types of construction projects.

Panel Discoloration

While UV PVC panels are engineered for superior light stability, discoloration can sometimes occur if low-quality alternatives are used or if the panels are exposed to extreme conditions.

- The Problem: Yellowing of the surface or fading of the wood veneer or marble pattern over several years.

- The Cause: Use of non-UV-rated panels in direct sun or the use of harsh chemical cleaners that strip the protective lacquer.

- The Solution: Always ensure you are using panels from a reputable manufacturer like Haining Yunxi New Material Technology Co., Ltd., whose technological innovation ensures high UV-shielding standards. If fading has occurred, the only permanent solution is panel replacement.

Joint Separation

Gaps appearing between panels can detract from the seamless look required in modern home decoration.

- The Problem: Visible lines or physical gaps opening up between the interlocking edges of the panels.

- The Cause: This is often caused by thermal expansion and contraction if a sufficient expansion gap wasn't left at the floor and ceiling, or if a low-quality adhesive failed to bond.

- The Solution: For minor gaps, use a color-matched professional sealant to fill the joint. To prevent this, ensure that the substrate is completely dry before installation and use high-strength, neutral-cure adhesives.

Impact Damage

Although UV PVC panels are highly durable, extreme force from sharp or heavy objects can result in physical damage.

- The Problem: Dents, cracks, or deep scratches on the decorative surface.

- The Cause: Accidental impact during furniture moving or intentional vandalism in commercial construction projects.

- The Solution:

- For Scratches: Minor surface scuffs can often be buffed out using a specialized UV-safe polish or automotive wax.

- For Dents/Cracks: Because these panels are installed individually, the damaged board can be carefully removed and replaced with a new one without disturbing the rest of the wall, showcasing the flexibility of this modern material.

Surface Bubbling

Occasionally, panels may appear to "blister" or bubble shortly after installation.

- The Problem: Small raised areas on the surface of the panel.

- The Cause: This is usually due to moisture trapped between the wall and the panel or an incompatible adhesive releasing gasses.

- The Solution: Ensure proper surface preparation as recommended by Haining Yunxi New Material Technology Co., Ltd. Walls must be moisture-tested, and the correct adhesive "snake" pattern must be used to allow for minimal air displacement.

UV PVC Panels vs. Alternatives

When selecting materials for modern home decoration or commercial construction projects, it is essential to compare UV PVC panels with traditional options. Haining Yunxi New Material Technology Co., Ltd. has focused on technological innovation to ensure their product system addresses the weaknesses commonly found in other materials like wood and metal.

Comparison with Other Materials

Understanding how UV PVC panels stack up against traditional wall coverings helps in making an informed decision for long-term value.

Vs. Natural Wood and Wood Veneer

- Moisture Performance: Natural wood absorbs water, leading to swelling, rotting, and mold. UV PVC panels are 100% waterproof and moisture-proof.

- Maintenance: Wood requires regular staining, oiling, or varnishing. The wood veneer patterns in the Haining Yunxi product system provide the same aesthetic warmth but require only a simple wipe to clean.

- Pest Resistance: PVC is naturally resistant to termites and other wood-boring insects that can devastate natural timber installations.

Vs. Metal Panels (Aluminum/Steel)

- Corrosion: Metal panels can rust or oxidize, especially in coastal or humid environments. PVC is chemically inert and will never corrode.

- Cost and Weight: UV PVC panels are significantly lighter and more cost-effective than high-end metallic cladding, reducing both material spend and structural load.

- Denting: While metal can be permanently dented by minor impacts, the high-density core of UV PVC panels offers excellent resilience.

Vs. Standard PVC (Non-UV Treated)

- Surface Hardness: Standard PVC is relatively soft and prone to scratching. The UV curing process creates a "stone-hard" surface that is much more durable.

- Visual Fidelity: The UV coating enhances the clarity of the design layer, making marble and wood grains look far more realistic than the "plastic" look of standard panels.

Pros and Cons of Each

| Material | Pros | Cons |

| UV PVC Panels | Waterproof, UV-resistant, low maintenance, realistic luxury designs. | Requires flat surface for best adhesive bond. |

| Natural Wood | Authentic feel, renewable. | High maintenance, prone to rot and pests, expensive. |

| Metal Cladding | Modern industrial look, high fire resistance. | Expensive, can rust, difficult to cut on-site. |

Why UV PVC Panels Win

For most modern construction projects, UV PVC panels offer the best balance of performance and aesthetics. By mimicking premium materials while removing their inherent flaws, the rich product system from Haining Yunxi New Material Technology Co., Ltd. provides a versatile solution that is loved and favored by consumers globally. Their rapid pace of development in brand building and technological innovation ensures these panels remain the superior choice for high-durability, high-style environments.

Future Trends in UV PVC Panels

As a forward-thinking modern enterprise, Haining Yunxi New Material Technology Co., Ltd. is at the forefront of the industry's rapid evolution. Technological innovation is driving the next generation of UV PVC panels, ensuring they remain the preferred choice for both sophisticated home decoration and complex construction projects.

Innovations in Manufacturing

The manufacturing landscape is shifting toward higher precision and enhanced material properties. Recent advancements include:

- High-Definition 3D Printing: New printing techniques allow for even greater visual depth, creating wood veneer and stone patterns that are indistinguishable from the natural materials they replicate.

- Nano-Ceramic Topcoats: The integration of nanotechnology into the UV curing process is creating surfaces with even higher scratch resistance and self-healing properties.

- Improved Core Stability: Research into composite substrates is reducing the thermal expansion coefficient, making panels even more reliable for large-scale exterior cladding.

Sustainability Efforts

Environmental responsibility is a core pillar of modern brand building. Haining Yunxi New Material Technology Co., Ltd. and other industry leaders are focusing on eco-friendly developments such as:

- Recycled Content: Increasing the percentage of recycled PVC in the base substrate without compromising the structural integrity of the panels.

- VOC-Free Production: Utilizing UV-curing lacquers that contain zero volatile organic compounds, ensuring better indoor air quality for residential styles of home decoration.

- Circular Economy: Developing panels that are 100% recyclable at the end of their multi-decade lifespan, reducing the environmental footprint of construction projects.

Emerging Applications

Beyond traditional wall cladding, UV PVC panels are finding new roles in the design world:

- Smart Surfaces: Integration of touch-sensitive technology into panels for home automation control in modern "smart homes."

- Acoustic Optimization: Perforated UV PVC panels designed to provide sound dampening in commercial offices and healthcare facilities.

- Furniture Surfacing: Using thin, flexible UV PVC veneers to resurface cabinetry and wardrobes, providing a durable and stylish alternative to traditional laminates.

Conclusion of Trends

The rapid pace of development in these areas ensures that UV PVC panels will continue to be loved and favored by consumers. By staying committed to independent research and development, Haining Yunxi New Material Technology Co., Ltd. ensures that their rich product system remains a benchmark for quality and innovation in the global market.

Conclusion

Throughout this guide, we have explored the multifaceted world of UV PVC panels and why they have become a cornerstone of the modern building material industry. From their incredible resistance to the elements to their nearly limitless design potential, these panels offer a superior alternative to traditional cladding. Haining Yunxi New Material Technology Co., Ltd. has played a pivotal role in this evolution, maintaining a long-term focus on the independent research and development and production of wood veneer wall panels and flooring.

Recap of Benefits and Uses

UV PVC panels stand out in the market for several key reasons that make them suitable for a wide variety of styles of home decoration and industrial applications:

- Unmatched Durability: The UV-cured surface ensures resistance to scratches, impacts, and daily wear, providing a long-lasting solution for any environment.

- Environmental Resilience: Their 100% waterproof and UV-resistant nature allows them to perform flawlessly in bathrooms, kitchens, and even exterior settings.

- Hygienic and Low Maintenance: The non-porous surface naturally resists mold, bacteria, and stains, requiring only minimal effort to keep clean.

- Versatile Applications: Whether used in residential living rooms, sterile healthcare facilities, or rugged agricultural buildings, these panels adapt to the specific needs of various types of construction projects.

Final Thoughts: Why UV PVC Panels are a Smart Choice

Choosing UV PVC panels is more than just an aesthetic decision; it is a strategic investment in quality and efficiency. As an all-round development of modern enterprise, Haining Yunxi New Material Technology Co., Ltd. has demonstrated that through technological innovation and a rich product system, it is possible to achieve luxury results without the high costs and maintenance burdens of natural stone or wood.

The rapid pace of development in brand building and team management within the industry has ensured that these materials are now more accessible, durable, and beautiful than ever before. It is no surprise that they continue to be loved and favored by consumers worldwide. For your next project, whether it is a simple home refresh or a complex commercial build, the UV PVC panel remains the most innovative and reliable choice for the future of interior and exterior design.

FAQ

Are UV PVC panels safe for residential use?

Yes, premium panels from reputable manufacturers like Haining Yunxi New Material Technology Co., Ltd. are produced using VOC-free processes, ensuring they are safe for indoor air quality in all residential settings.

Can I install these panels myself?

While professional installation is recommended for complex construction projects, the lightweight nature and simple adhesive application make them an excellent choice for DIY home decoration projects.

How do I ensure the color matches across a large area?

To ensure perfect consistency, it is always recommended to purchase panels from the same production batch. Working with a supplier that has a rich product system and strict quality control will help maintain visual uniformity across large installations.

Technical Specifications and Quality Standards

For large-scale construction projects and professional contractors, understanding the technical benchmarks of the rich product system from Haining Yunxi New Material Technology Co., Ltd. is essential. The enterprise’s rapid pace of development in technological innovation has led to the establishment of high-tier internal quality controls that meet and exceed industry expectations.

Material Performance Metrics

The UV PVC panels produced through independent research and development adhere to rigorous performance standards to ensure they are loved and favored by consumers for their reliability:

- Surface Hardness: Achieving high levels on the Mohs scale through specialized UV curing, ensuring the decorative layer resists abrasions in high-traffic commercial zones.

- Fire Retardancy: Classified under the Class B1 standard, making them a safe choice for public construction projects, including schools and hospitals.

- Density Consistency: High-density PVC substrates provide better screw-holding strength for mechanical fastening, a critical factor for exterior cladding.

- Thermal Stability: Advanced formulations minimize expansion and contraction, ensuring the panels remain perfectly aligned in environments with fluctuating temperatures.

Brand Excellence and Modern Enterprise Values

The success of Haining Yunxi New Material Technology Co., Ltd. in brand building and team management is reflected in the consistency of their output. As an all-round development of modern enterprise, they focus on more than just the product; they focus on the solution:

Technological Innovation in Design

By constantly updating their manufacturing technology, they can offer a wider variety of textures and finishes, ensuring that their panels meet the needs of various styles of home decoration, from the most traditional to the ultra-modern.

Quality Assurance for Construction Projects

Every batch of panels undergoes strict testing for UV stability and moisture resistance. This commitment to quality is why their rich product system has gained significant attention in the industry and has become a preferred partner for international construction firms.

Final Industry Outlook

As we look toward the future, the integration of high-performance materials like UV PVC panels will continue to redefine the architectural landscape. Through the efforts of pioneering companies like Haining Yunxi New Material Technology Co., Ltd., the industry will see even more sustainable, durable, and aesthetically stunning materials that continue to capture the market's attention and drive global design trends.