+86-18367343973

- 1 1. Why Choose Flexible Stone Wall Panels?

- 2 2. Application Scenarios via Long‑Tail Keywords

- 2.1 2.1 flexible stone wall panels for curved surfaces – Curved wall applications

- 2.2 2.2 flexible stone wall panels exterior facade installation – Exterior façade guidance

- 2.3 2.3 flexible stone wall panels interior feature wall guide – Interior feature‑wall installation

- 2.4 2.4 flexible stone wall panels rapid installation method – Speed and efficiency

- 2.5 2.5 flexible stone wall panels maintenance and cleaning tips – Longevity and upkeep

- 3 3. Step‑by‑Step Installation Processes (by type)

- 4 4. Key Factors for Fast and Effective Installation

- 5 5. Maintenance, Cleaning and Extending Lifespan

- 6 6. About Haining Yunxi New Material Technology Co., Ltd.

- 7 FAQ

In modern architecture and interior design, the demand for natural stone aesthetics combined with flexible installation methods is growing rapidly. By leveraging Flexible Stone Wall Panels, professionals and homeowners alike can achieve sophisticated surfaces on curved walls, exterior façades and interior walls — with reduced weight, faster installation and increased design freedom. At Haining Yunxi New Material Technology Co., Ltd., we have long been focusing on the independent research and development and production of wood veneer wall panels and flooring and have a rich product system in the industry. While our heritage lies in wood veneer systems, we fully understand the broader wall‑cladding market and can provide guidance on selecting and installing flexible stone systems that meet both aesthetic and construction demands.

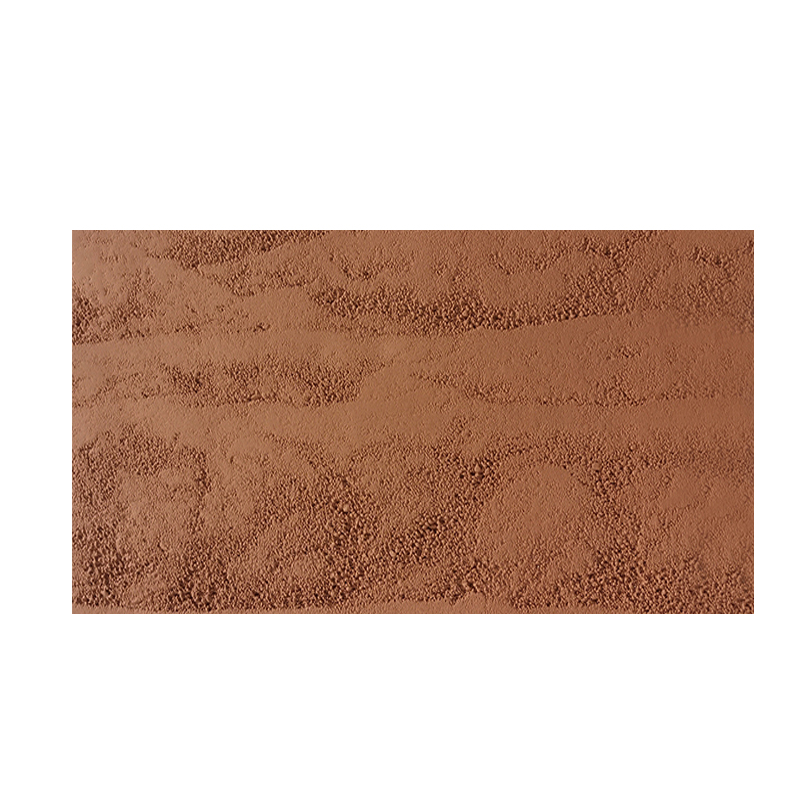

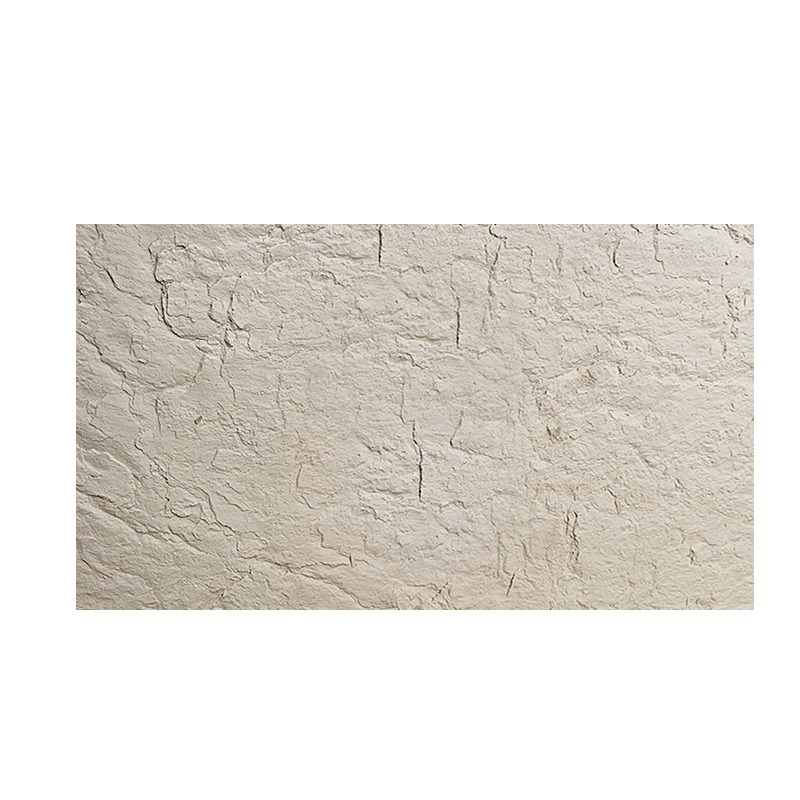

Flexible Stone Veneer Sheet - Weatherproof & Lightweight Exterior Cladding for Walls YXCL-REA7

1. Why Choose Flexible Stone Wall Panels?

1.1 Lightweight, flexible, ideal for curved surfaces

- Flexible stone panels are typically less than 2 mm thick and weigh a fraction of conventional stone cladding — making them suitable for curved walls, columns and unconventional surfaces.

- Because they bend, the long‑tail keyword flexible stone wall panels for curved surfaces is especially relevant in projects with arches or rounded surfaces.

1.2 Interior & exterior application scenarios

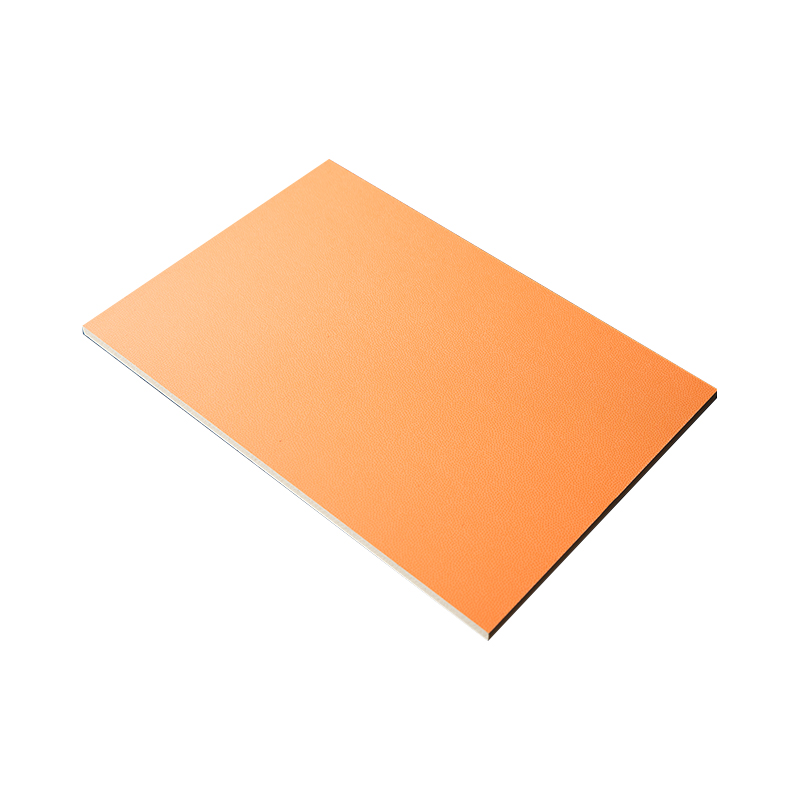

- These panels perform well in interior feature walls, bathrooms and commercial lobbies, as well as in exterior façades and outdoor applications when properly sealed.

- The long‑tail keyword flexible stone wall panels exterior facade installation speaks to their use on outdoor walls and façades.

1.3 Comparison with traditional stone systems

Comparing the two systems helps clarify why flexible stone panels are gaining traction.

| Feature | Traditional Stone Cladding | Flexible Stone Wall Panels |

| Weight | Heavy, requires structural support | Lightweight, minimal structural load |

| Flexibility | Rigid, only flat surfaces | Bends around curves and complex shapes |

| Installation speed | Labor intensive, slower | Faster, simpler adhesive‑based method |

| Thickness | Often >15 mm | Often <2 mm |

---

2. Application Scenarios via Long‑Tail Keywords

2.1 flexible stone wall panels for curved surfaces – Curved wall applications

- Use on curved lobby walls, spiral staircases or rounded kitchen islands.

- Ensure the substrate is smooth and primed; plan panel cuts to wrap the curvature.

2.2 flexible stone wall panels exterior facade installation – Exterior façade guidance

- Select panels rated for UV exposure and outdoor moisture; apply protective sealant.

- Install a ventilation gap or drainage plane if used on rainscreen façades.

2.3 flexible stone wall panels interior feature wall guide – Interior feature‑wall installation

- Popular in residential living rooms, hotel lobbies, commercial reception areas.

- Focus on alignment, lighting and accent‑trim details to maximise the stone effect.

2.4 flexible stone wall panels rapid installation method – Speed and efficiency

- Premeasure panel areas and mark joints; use adhesive rollers or trowels for speed.

- Because the panels are lightweight, one worker can often handle installation with minimal lifting equipment.

2.5 flexible stone wall panels maintenance and cleaning tips – Longevity and upkeep

- Use mild soap and water for regular cleaning; avoid harsh acids or abrasive tools.

- Inspect annually for edge lifts, reseal exposed outer edges if required.

---

3. Step‑by‑Step Installation Processes (by type)

3.1 Curved wall installation steps

3.1.1 Surface preparation

- Ensure the curved substrate is smooth, stable, clean and dry.

- Remove dust, repair any defects and apply primer suitable for the adhesive.

3.1.2 Bending, loading & adhesive application

- Pre‑cut the panels to approximate size, leaving small gaps for expansion.

- Apply high‑strength adhesive to the back of the panel and press onto the curve, using a roller to eliminate air pockets.

3.2 Exterior façade / wall installation steps

3.2.1 Waterproofing & UV protection

- Apply a weather‑resistant membrane if required; choose sealant compatible with stone surface.

- Guard against direct constant UV exposure and water intrusion via proper detailing.

3.2.2 Fixing system & backing structure

- Use a ventilated sub‑frame or rainscreen panel where applicable; fix panels with mechanical fasteners if needed along with adhesive.

- Leave movement joints and expansion gaps around windows, doors and large panels.

3.3 Interior wall installation steps

3.3.1 Wall base & leveling

- Check that drywall or substrate is flat within tolerance (e.g., ±2 mm over 2 m).

- Install stop‑beads at corners and use a straightedge to verify level.

3.3.2 Cutting, joint alignment & finishing

- Cut panels with utility knife or snips; align joints carefully so the stone grain flows consistently.

- Finish edges with matching trim or natural stone edge to avoid visible substrate.

| Traditional Stone Cladding | Flexible Stone Wall Panels | |

| Typical adhesive method | Mortar bed or mechanical anchors | Polyurethane or epoxy adhesive, minimal anchor points |

| Movement accommodation | Often rigid, limited movement | Better accommodation for substrate movement due to flexible backing |

| Installation labour | Requires heavy lifting, scaffolding | Lightweight panels, faster turnaround |

---

4. Key Factors for Fast and Effective Installation

4.1 Use correct adhesive and backing system

- Select adhesives rated for stone and outdoor use where applicable.

- Ensure the backing structure is stable; for curved surfaces the backing should follow the contour smoothly.

4.2 Include expansion joints and proper corner/edge detailing

- Design movement joints every 3–4 m horizontally or as specified to prevent buckling.

- Handle internal and external corners with prefabricated trims or mitre‑cut panels for a clean finish.

4.3 Quality control and safety protocols

- Check flatness, adhesion coverage (≥ 90%) and correct alignment before panel curing.

- Ensure workers use correct PPE and that scaffolding is safe for exterior installations.

---

5. Maintenance, Cleaning and Extending Lifespan

5.1 Regular cleaning routine

- Wipe surfaces with a soft cloth and mild neutral pH detergent; rinse with clean water.

- Avoid acidic or strong alkaline cleaners, which may dull natural stone finish.

5.2 Annual inspection and resealing

- Inspect joints, edges and surfaces for delamination, cracking or edge lifts.

- If used outdoors or in wet zones, apply a breathable stone sealer every 12–24 months.

5.3 Common fault diagnosis (edge peel, cracking, fading)

- Edge peeling often results from insufficient adhesive or movement allowance.

- Cracking may occur if substrate deflection exceeds panel tolerance; check structural movement.

- Fading is rare if stone is natural and sealer is correct; inspect UV‑exposed edges regularly.

---

6. About Haining Yunxi New Material Technology Co., Ltd.

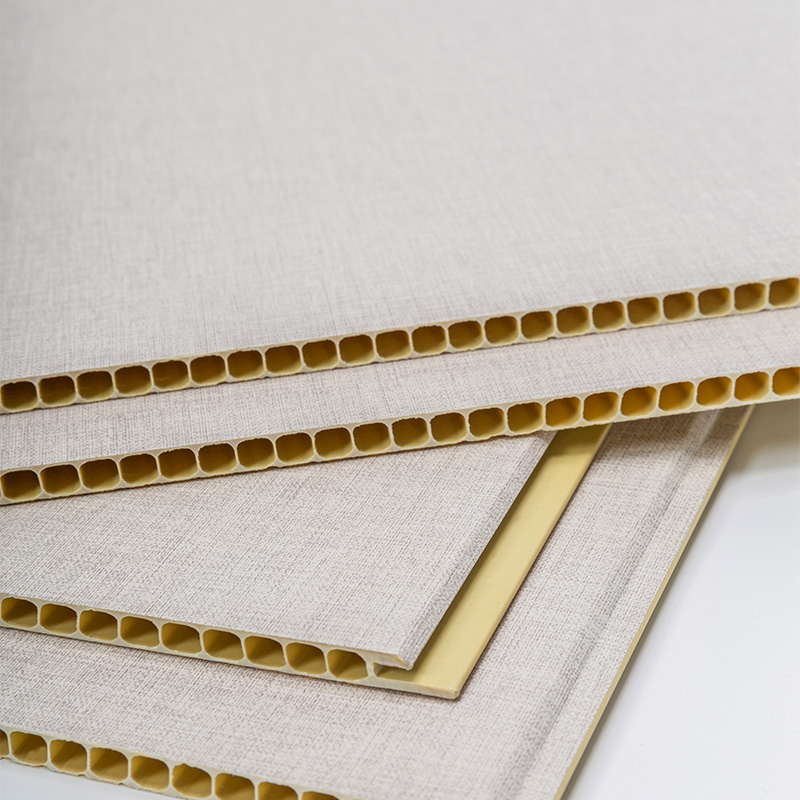

6.1 Company overview and R&D strength

Haining Yunxi New Material Technology Co., Ltd. has long been focused on independent research and development and production of wood veneer wall panels and flooring and has developed a rich product system in the industry. The company not only fully meets the needs of various styles of home decoration but also caters to diverse types of construction projects, earning consumer favour. As a modern enterprise, in recent years the company has rapidly advanced in technological innovation, brand building and team management, attracting significant industry attention.

6.2 Choosing the right flexible stone wall panel system

- Although Yunxi specialises in wood veneer systems, their deep experience in surface materials means they understand substrate, adhesion and finishing criteria for wall‑cladding systems.

- When selecting a suitable flexible stone panel solution for your project (curved wall, exterior façade or interior feature wall), ensure the system provider offers: certificate of authenticity, sample verification, installation guidelines and after‑sales support.

- Yunxi's understanding of manufacturing, logistics and surface finishing supports clients in specifying flexible stone wall panels that meet aesthetic, structural and installation requirements.

FAQ

- Q1: What exactly are Flexible Stone Wall Panels?

A1: They are ultra‑thin real stone veneers bonded to a flexible backing material, allowing installation on curved, flat or complex surfaces with less structural load than traditional stone. - Q2: Can these panels be used outdoors for façades?

A2: Yes — when properly sealed and installed with drainage/ventilation behind the panels, the system is suitable for exterior applications, aligning with the keyword flexible stone wall panels exterior facade installation. - Q3: How do installation time and cost compare to traditional stone?

A3: The installation is significantly faster and lighter, reducing labour, scaffolding and support costs; this corresponds to the keyword flexible stone wall panels rapid installation method. - Q4: What maintenance is required for curved wall or interior installations?

A4: Regular cleaning with mild detergent, annual inspection and resealing where exposure to moisture or UV is high; see keyword flexible stone wall panels maintenance and cleaning tips. - Q5: How do I choose the right system for a curved interior feature wall?

A5: For curved surfaces, select a system rated for bending, check sample curvature radius, verify substrate readiness and follow the guidance for flexible stone wall panels for curved surfaces.