Exploring the Advantages and Unique Features of WPC Co-extruded Boards: What Makes Them Stand Out?

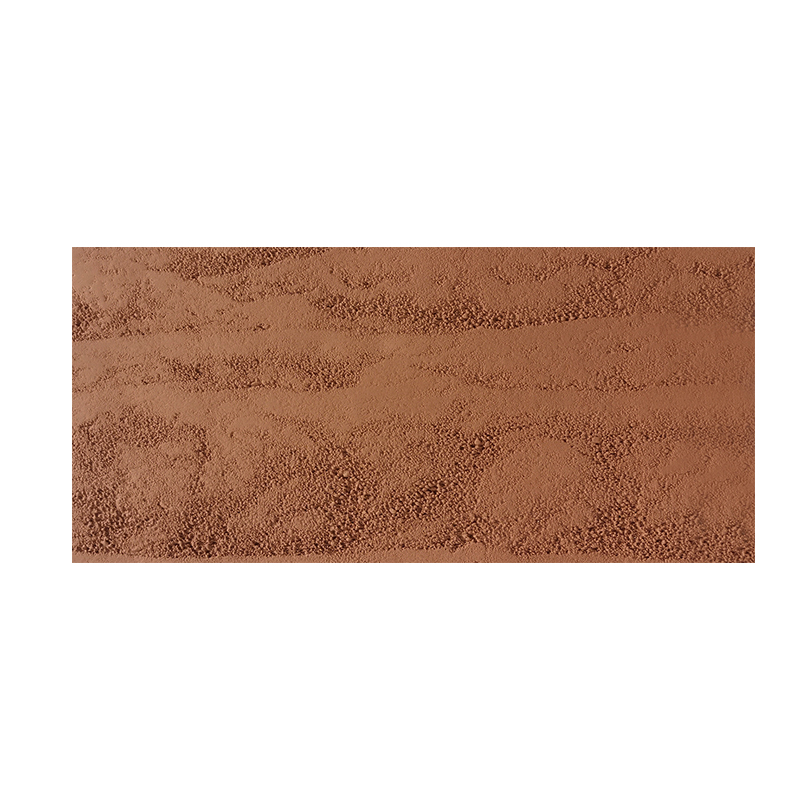

WPC Co-extrusion Panel, the full name of wood-plastic composite co-extrusion board, is a board made by mixing plastic, wood fiber powder and specific additives in a certain proportion, and then going through an advanced co-extrusion molding process. This kind of board not only inherits the texture beauty of wood, but also overcomes the shortcomings of traditional wood that is susceptible to moisture, corrosion, and deformation. At the same time, it has the excellent properties of plastic such as waterproof, anti-corrosion, and weather resistance. It is particularly worth mentioning that the surface of the second-generation WPC Co-extrusion Panel also has a uniform and strong coating co-extrusion layer, which significantly improves its mildew resistance, insect resistance, wear resistance, scratch resistance, stain resistance and weather resistance. It is especially suitable for public places with large flow of people and complex usage environment.

Environmental protection and energy saving: WPC Co-extrusion Panels are made of renewable and recycled wood fiber and plastic materials, which eliminates the need to cut down a large number of trees, effectively reducing dependence on natural resources and in line with the development trend of green building materials.

Excellent performance: Through co-extrusion technology, a dense protective layer is formed on the surface of the board, which greatly improves its wear resistance, scratch resistance, stain resistance and other properties. At the same time, good weather resistance ensures the stable performance of the board under different climate conditions.

Diverse designs: The WPC co-extruded board series provided by the company has a rich selection of colors and textures, which can meet the needs of different decoration styles and engineering projects. Whether it's a home renovation or a commercial space, you'll find the ideal choice.

Easy installation: WPC co-extruded panels adopt a modular design, which makes installation simple and fast, reducing construction difficulty and cost, and improving project efficiency.

Waterproof and moisture-proof: Due to the addition of plastic substrate, WPC co-extruded board has excellent waterproof performance and can remain stable even in humid environments.

Anti-corrosion and insect-proof: Compared with solid wood, WPC co-extruded boards are less susceptible to insects and rot, extending their service life.

Strong weather resistance: The specially treated surface co-extruded layer enables the WPC co-extruded board to withstand the effects of harsh weather conditions such as ultraviolet rays, high temperatures, and low temperatures, and maintain long-term stability.

Diverse appearance: WPC co-extruded boards can simulate the textures and colors of various natural woods, and can even achieve customized designs to meet the needs of different decorative styles.

Wear-resistant and scratch-resistant: The surface co-extruded layer enhances the hardness and wear-resistance of the board, allowing it to maintain a good appearance even in high-traffic areas.

Easy to clean and maintain: The surface is smooth and flat, not easily contaminated with dust and stains, making cleaning and maintenance more convenient and faster.

Haining Yunxi New Material Technology Co., Ltd.'s outstanding performance in the field of WPC Co-extrusion Panels is inseparable from its strong R&D strength and technological innovation capabilities. The company has a professional R&D team that constantly explores the application of new materials and new processes, and is committed to launching more environmentally friendly, high-performance, and cost-effective products. At the same time, the company also actively participates in the formulation and revision of industry standards to promote the healthy development of the entire industry.

As people's awareness of environmental protection continues to increase and the building decoration industry's demand for high-performance materials grows, WPC co-extruded panels, as a new building material that integrates environmental protection, beauty and durability, will have an increasingly broad market prospect. With its strong technical strength, rich product system and good market reputation, Haining Yunxi New Material Technology Co., Ltd. will continue to lead the trend in this field and provide consumers with more high-quality, environmentally friendly WPC Co-extrusion Panels. product.