+86-18367343973

- 1 Why Choose curved wall panels for modern interiors?

- 2 Exploring acoustic curved wall panel solutions for better sound quality

- 3 Custom curved wall panel designs for unique spaces

- 4 Comparing curved wall panel materials comparison for durability and aesthetics

- 5 Essential curved wall panel installation techniques professionals use

Why Choose curved wall panels for modern interiors?

Curved wall panels have become increasingly popular in contemporary architecture and interior design. Unlike traditional flat walls, these flowing structures create dynamic spaces with organic appeal. The curved wall panels for modern interiors offer several advantages that make them worth considering for your next project.

Bendable Wall Wood Veneer Background Wall Panel YXWPC1228-A++

Benefits of Curved Wall Panels

- Enhanced aesthetic appeal with fluid, organic lines

- Improved acoustics as curved surfaces diffuse sound waves

- Space optimization in awkward corners or irregular layouts

- Visual interest that breaks the monotony of straight walls

- Structural advantages in certain architectural applications

Comparing Curved vs. Flat Wall Panels

When deciding between curved and traditional flat panels, consider these key differences:

| Feature | Curved Panels | Flat Panels |

|---|---|---|

| Visual Impact | High - creates focal points | Low - conventional appearance |

| Installation Complexity | Moderate to high | Low |

| Material Options | Somewhat limited | Virtually unlimited |

| Space Efficiency | Excellent for awkward spaces | Standard |

| Cost | Typically 20-40% higher | Lower baseline |

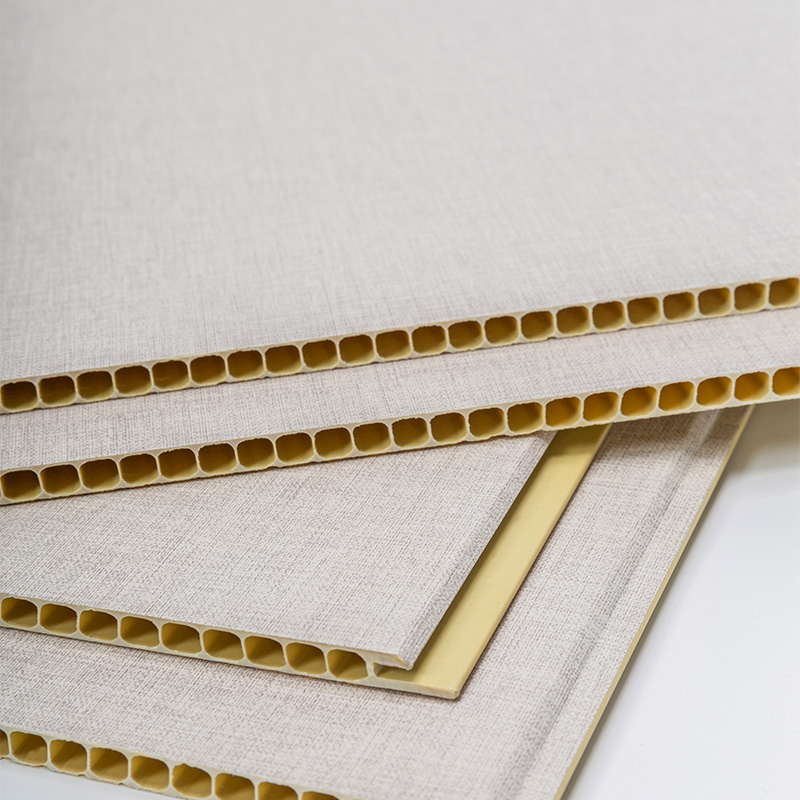

Exploring acoustic curved wall panel solutions for better sound quality

The acoustic curved wall panel solutions combine aesthetic appeal with functional sound management. These specialized panels are designed to address various acoustic challenges while maintaining beautiful curved designs.

How Acoustic Curved Panels Work

Acoustic curved panels utilize several principles to improve sound quality:

- Diffusion: The curved surfaces scatter sound waves rather than reflecting them directly

- Absorption: Many incorporate porous materials that trap sound energy

- Bass trapping: Some designs specifically target low-frequency absorption

- Reflection control: Helps eliminate problematic echoes and flutter

Applications for Acoustic Curved Panels

These panels excel in environments where both aesthetics and sound quality matter:

- Recording studios and home theaters

- Conference rooms and auditoriums

- Restaurants and hospitality spaces

- Open-plan offices needing sound control

- Performance venues and music rooms

Custom curved wall panel designs for unique spaces

For projects requiring specific dimensions or aesthetic qualities, custom curved wall panel designs offer the perfect solution. These tailor-made panels can transform ordinary spaces into extraordinary environments.

The Custom Design Process

Creating custom curved panels involves several key steps:

- Initial consultation to understand spatial requirements

- Concept development with 3D modeling

- Material selection based on functional needs

- Prototyping (for complex designs)

- Fabrication using specialized techniques

- Installation by experienced professionals

Popular Customization Options

When ordering custom panels, consider these possibilities:

- Radius variations from gentle curves to tight spirals

- Integrated lighting solutions within the panel design

- Mixed material compositions (wood/metal/glass combinations)

- Surface treatments including textures and patterns

- Modular systems for flexible configurations

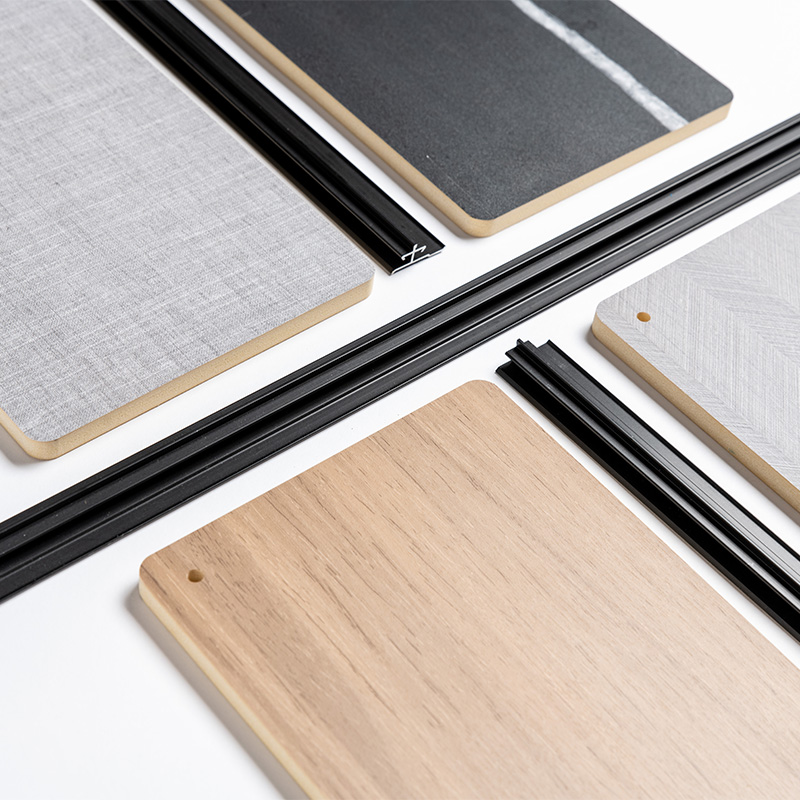

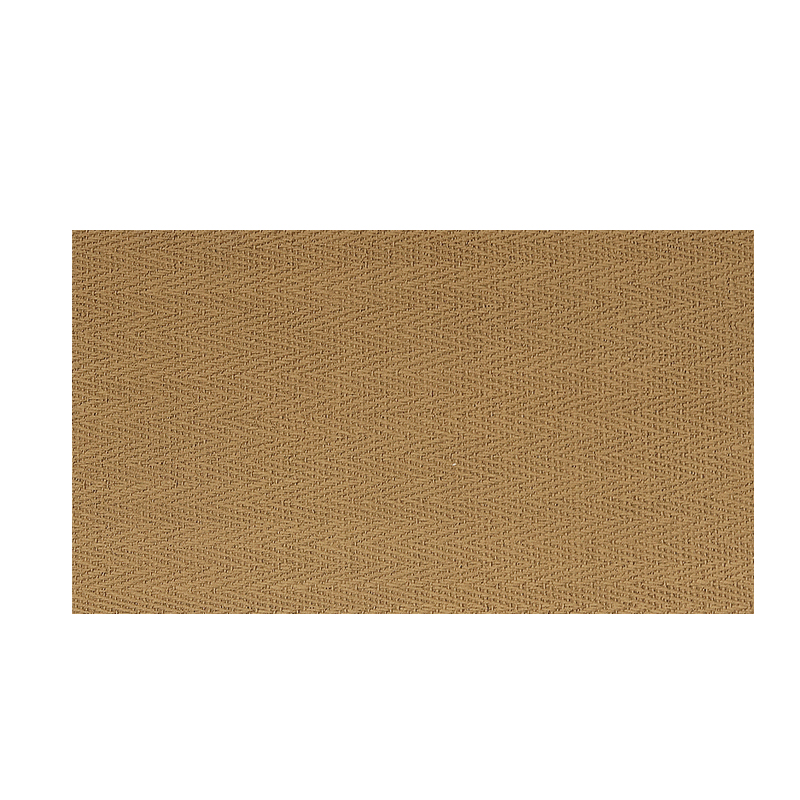

Comparing curved wall panel materials comparison for durability and aesthetics

Selecting the right material is crucial for both performance and appearance. This curved wall panel materials comparison examines the most common options available.

Material Options and Characteristics

| Material | Durability | Cost | Maintenance | Best Uses |

|---|---|---|---|---|

| Medium Density Fiberboard (MDF) | Moderate | Low | High (painted surfaces) | Indoor decorative applications |

| Gypsum | Low to moderate | Low | Moderate | Painted interior walls |

| Wood Veneer | High | Medium to high | Low | Premium interiors |

| Metal (Aluminum) | Very high | High | Very low | Commercial spaces, exteriors |

| High-Pressure Laminate | High | Medium | Low | High-traffic areas |

Factors Affecting Material Choice

When selecting materials for curved panels, consider:

- Environmental conditions (humidity, temperature fluctuations)

- Required fire ratings for commercial applications

- Acoustic performance needs

- Weight limitations of the supporting structure

- Desired aesthetic and tactile qualities

Essential curved wall panel installation techniques professionals use

Proper installation is critical for achieving both the desired look and long-term performance. These curved wall panel installation techniques represent industry best practices.

Preparation Steps Before Installation

Successful installation begins with thorough preparation:

- Accurate measurement of the space using laser levels

- Creation of detailed templates for complex curves

- Substrate preparation to ensure proper adhesion

- Climate control in the installation area

- Dry fitting of panels to verify fit

Key Installation Methods

Different materials and designs require specific approaches:

- Adhesive mounting for lightweight panels

- Mechanical fastening for structural applications

- Track systems for modular panel arrangements

- Floating installations with concealed supports

- Interlocking systems for seamless appearances

Common Installation Challenges and Solutions

| Challenge | Solution |

|---|---|

| Panel warping during installation | Use temporary bracing until adhesive sets |

| Visible seams on tight curves | Employ specialized joining techniques |

| Alignment issues on long runs | Establish and maintain reference lines |

| Material springback | Allow for proper acclimation time |

| Surface imperfections | Use fillers matched to panel material |