+86-18367343973

- 1 Understanding SPC Flooring and Its Installation Requirements

- 2 Installing SPC Flooring on Concrete Subfloors

- 3 Installing SPC Flooring over Existing Tile

- 4 Using SPC Flooring on Wood Subfloors

- 5 SPC Flooring and Underfloor Heating Compatibility

- 6 Comparing Substrate Suitability for SPC Flooring

- 7 FAQ

- 7.1 Can SPC flooring be installed directly over an old vinyl floor?

- 7.2 What is the maximum moisture level for a concrete subfloor before installing SPC?

- 7.3 Do I always need an underlayment for SPC flooring?

- 7.4 Is SPC flooring a good choice for a bathroom or kitchen?

- 7.5 Can I install SPC flooring in a garage?

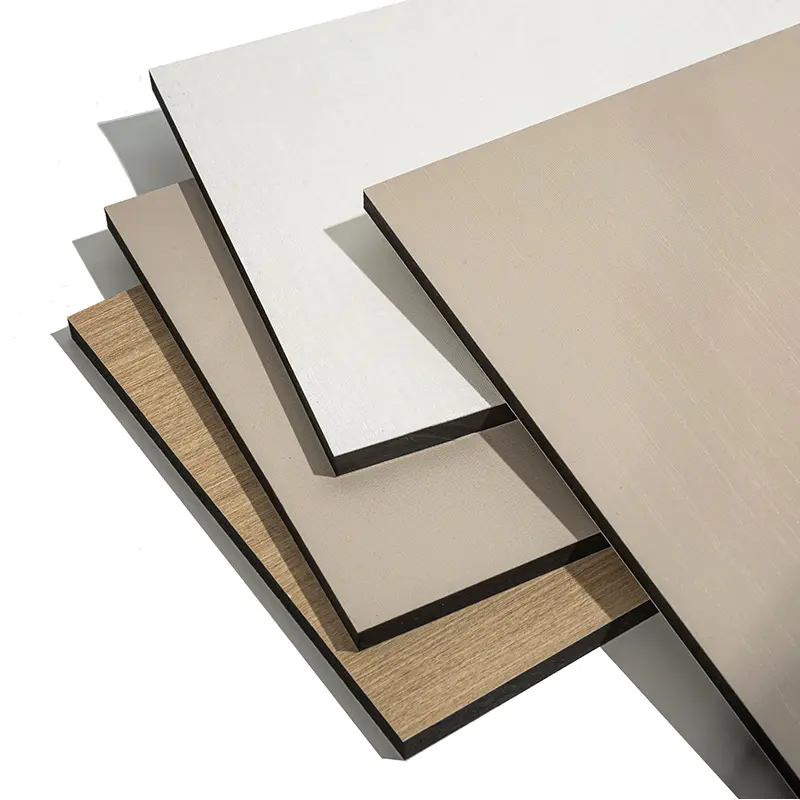

Stone Plastic Composite (SPC) flooring has revolutionized the modern flooring industry with its exceptional durability, waterproof nature, and realistic aesthetics. A key factor contributing to its widespread popularity is its remarkable versatility when it comes to installation substrates. Understanding what surfaces SPC flooring can be installed on is crucial for a long-lasting and successful project. This guide delves deep into the various acceptable subfloors, offering professional insights to ensure your installation is flawless. As a leader in the field, Haining Yunxi New Material Technology Co., Ltd. leverages its extensive R&D in flooring to produce SPC flooring that performs exceptionally across diverse subfloor conditions, meeting the rigorous demands of both residential and commercial projects.

Environmentally friendly household and commercial premier SPC lock floor Thickness 5.5 YXSPC22855

Understanding SPC Flooring and Its Installation Requirements

Before exploring the specific substrates, it's essential to understand why SPC flooring is so adaptable. Its rigid core, composed of limestone powder and stabilizers, provides exceptional dimensional stability. This means it doesn't expand or contract with temperature and humidity changes as much as other flooring types, allowing for installation over a wider range of subfloors. However, one universal requirement remains paramount: the subfloor must be perfectly flat, clean, dry, and structurally sound. Any deviation from this can lead to issues such as clicking sounds, joint damage, or an uneven appearance.

- Flatness: The subfloor should not have deviations greater than 3mm over a 1-meter radius. Any high or low spots must be leveled.

- Cleanliness: The surface must be free of all dust, debris, wax, oil, and any existing adhesive residue.

- Dryness: For concrete subfloors, a moisture test is recommended. The relative humidity should typically be below 75%.

- Stability: The subfloor should not have any movement or flex when walked upon.

Installing SPC Flooring on Concrete Subfloors

Concrete is one of the most common subfloors for SPC flooring installation, particularly in basements and ground-level constructions. It provides a solid and stable base, but special attention must be paid to moisture. A concrete slab, especially below grade, can wick moisture from the ground, which can damage the flooring over time if not properly addressed.

- Always conduct a moisture test using a calcium chloride test or a relative humidity meter before installation.

- If moisture levels are high, apply a dedicated moisture barrier or vapor-retarding underlayment.

- Ensure the concrete is fully cured (typically at least 60 days old).

- For below-grade installations, an additional vapor barrier is often mandatory.

Preparing Your Concrete Subfloor

Adequate preparation is the most critical step for a successful how to prepare concrete for SPC flooring. This process ensures the longevity and performance of your floor. Start by thoroughly cleaning the surface and then proceed to check for flatness and moisture.

- Fill any cracks or holes with a concrete patching compound.

- Grind down any high spots and use a self-leveling underlayment to fill low spots.

- A professional-grade moisture barrier underlayment is highly recommended for all concrete subfloors, regardless of the initial moisture reading.

Installing SPC Flooring over Existing Tile

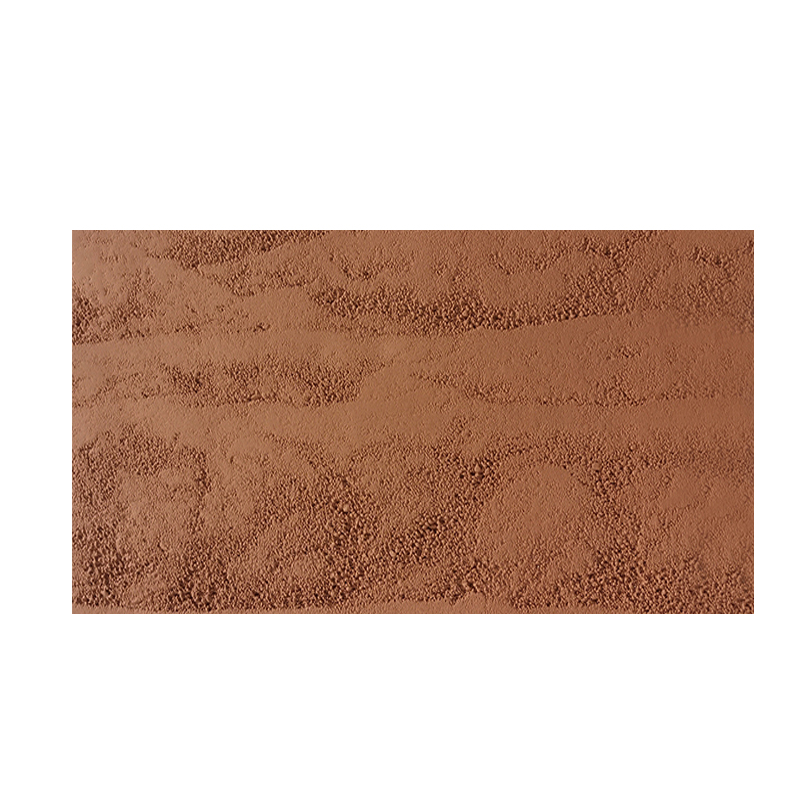

One of the most convenient installation methods is laying SPC flooring directly over existing ceramic or porcelain tile. This can save significant time and money on demolition. The rigid core of SPC is capable of bridging the grout lines, creating a smooth, new surface. This is a prime example of a SPC flooring over tile problems-free solution when done correctly.

- The existing tile must be firmly adhered to the subfloor with no loose or cracked pieces.

- Grout lines must be filled if they are deeper than the thickness of a dime to prevent telegraphing.

- The surface of the tile must be cleaned and degreased to ensure proper adhesion of the underlayment.

- Using an underlayment with a vapor barrier is still recommended to provide a perfectly flat surface and additional moisture protection.

Achieving a Smooth Transition

When installing over tile, transitions between rooms can become elevated. To manage this, transition strips are used to create a smooth, safe ramp between different floor heights. Proper planning for door clearances is also essential.

Using SPC Flooring on Wood Subfloors

Plywood or oriented strand board (OSB) subfloors are common in wood-frame construction and are excellent substrates for SPC flooring. The key concern here is not moisture from below, but the potential for vertical movement (deflection) and the presence of any protruding fasteners.

- Ensure the wood subfloor is securely fastened to the joists, with screws every 6 inches along the joists to eliminate squeaks.

- Sand down any high spots, including raised nail or screw heads, and fill large gaps between panels.

- A standard underlayment is sufficient for wood subfloors to provide cushioning and sound absorption. A moisture barrier is not typically required unless the subfloor is over a crawl space with high humidity.

Addressing Potential for Movement

Wood subfloors can expand and contract with seasonal humidity changes. While SPC's rigidity resists this, it's still crucial to leave the recommended expansion gap around the perimeter of the room to accommodate any minor movement in the subfloor.

SPC Flooring and Underfloor Heating Compatibility

A significant advantage of SPC flooring is its compatibility with radiant floor heating systems, making it a popular choice for modern homes. Its excellent thermal conductivity allows heat to transfer efficiently from the system to the room. However, specific protocols must be followed to prevent damage. This makes it an ideal solution for those wondering about best flooring for uneven concrete with heating, as its rigidity can help bridge minor inconsistencies when paired with a self-leveling underlayment.

- Confirm with the flooring manufacturer that their specific product is approved for use with underfloor heating.

- The heating system must be a hydronic (water-based) or low-voltage electric system, not high-voltage electric mats that can create hot spots.

- Before installation, the heating system must be activated and gradually increased to its maximum operating temperature for at least 72 hours, then completely turned off and cooled down to room temperature.

Installation and Operational Guidelines for Heated Floors

Following the correct procedure during and after installation is vital for systems using SPC flooring on radiant heat.

| Step | Action |

| Post-Installation | Wait at least 48-72 hours after installation before turning the heat on. |

| Activation | Slowly increase the temperature by no more than 5°F (3°C) per day until the desired temperature is reached. |

| Maximum Temperature | Never exceed the manufacturer's recommended maximum surface temperature, typically around 85°F (29°C). |

| Seasonal Use | Avoid rapid temperature swings. When turning the system on for the season, use the same gradual increase method. |

Comparing Substrate Suitability for SPC Flooring

To provide a clear overview, the following table compares the key considerations for the primary substrate types discussed. This is an excellent resource for understanding the SPC flooring installation nuances across different surfaces.

| Substrate Type | Primary Consideration | Underlayment Recommendation | Key Preparation Step |

| Concrete | Moisture Vapor Emission | Vapor Barrier + Cushion | Moisture Test and Leveling |

| Existing Tile | Surface Flatness | Standard or Vapor Barrier | Filling Deep Grout Lines |

| Wood (Plywood/OSB) | Structural Deflection | Standard Cushion | Securing Loose Panels and Sanding |

| Radiant Heat Systems | Temperature Control | Heat-Compatible Underlayment | Gradual System Activation |

FAQ

Can SPC flooring be installed directly over an old vinyl floor?

Yes, in many cases, SPC flooring can be installed over sheet vinyl or vinyl tiles, provided the existing floor is fully adhered, smooth, and in good condition. However, you must never install over cushioned vinyl, as it is too soft. It is also critical to ensure the surface is perfectly flat and clean. Any embossing or pattern on the old vinyl should be smoothed out, and all wax or polish must be removed. Installing a premium underlayment can help create a uniform surface. Haining Yunxi New Material Technology Co., Ltd. designs its flooring systems to be compatible with such installations, but always recommends a thorough subfloor assessment first.

What is the maximum moisture level for a concrete subfloor before installing SPC?

The maximum acceptable moisture level for a concrete subfloor is typically defined by the flooring manufacturer. However, a general industry standard is that the relative humidity (RH) measured within the concrete slab should not exceed 75%. For measurements using the calcium chloride test, the result should generally be below 3-5 pounds per 1,000 square feet per 24 hours. Exceeding these levels mandates the use of a highly effective vapor barrier underlayment. Ignoring high moisture levels is one of the leading causes of SPC flooring over tile problems and failures on concrete, as trapped moisture can lead to mold, mildew, and adhesive failure.

Do I always need an underlayment for SPC flooring?

While some SPC products come with a pre-attached underlayment, most installations benefit greatly from a separate, high-quality underlayment. Its functions are multifold: it acts as a moisture barrier (crucial for concrete), provides acoustic insulation by reducing impact noise, adds underfoot comfort, and helps smooth out minor subfloor imperfections. For a SPC flooring installation to achieve its maximum performance and longevity, an underlayment tailored to the specific subfloor type is a highly recommended investment.

Is SPC flooring a good choice for a bathroom or kitchen?

Absolutely. SPC flooring is an excellent choice for wet areas like bathrooms and kitchens due to its 100% waterproof core. Unlike laminate or engineered wood, spills and moisture will not cause the planks to swell, warp, or delaminate. This makes it ideal for how to prepare concrete for SPC flooring in basements that may have humidity concerns. Its durability also stands up well to the high traffic and dropped utensils common in kitchens. Ensuring a proper installation with tightly locked seams and, if desired, the use of a 100% silicone sealant along the edges, can make the floor virtually impervious to water.

Can I install SPC flooring in a garage?

Installing SPC flooring in a standard garage is generally not recommended. While the flooring itself is durable and waterproof, garages experience extreme temperature fluctuations, direct exposure to sunlight (which can cause fading), and the potential for chemical spills (oil, gasoline) that could stain or degrade the wear layer. Furthermore, the weight of a vehicle concentrated on jack stands can dent or damage the rigid core. For a garage, more specialized flooring like epoxy coatings or interlocking garage tiles are better suited. The focus of Haining Yunxi New Material Technology Co., Ltd. is on interior applications where the product's properties can be fully optimized for long-term performance.