+86-18367343973

SPC stone plastic composite flooring has revolutionized the modern flooring industry, offering a robust and versatile solution for both residential and commercial spaces. As a core component of the rigid core luxury vinyl tile (LVT) category, SPC stone plastic composite flooring is renowned for its dimensional stability, durability, and authentic aesthetic appeal. This guide delves deep into the specifics of SPC flooring, providing you with the expert knowledge needed to make an informed decision for your next project.

What is SPC Stone Plastic Composite Flooring?

At its core, SPC flooring is a type of rigid core vinyl flooring. Its construction is what sets it apart. The "stone plastic composite" refers to a core layer made from a mixture of limestone powder (calcium carbonate), polyvinyl chloride (PVC), and stabilizers. This mixture is compressed under high heat and pressure to create an incredibly dense and stable plank. This innovative core is then topped with a decorative vinyl layer that mimics materials like wood or stone, and a protective wear layer.

- Core Layer: The dense SPC core provides exceptional structural integrity, making it resistant to indentation and impact.

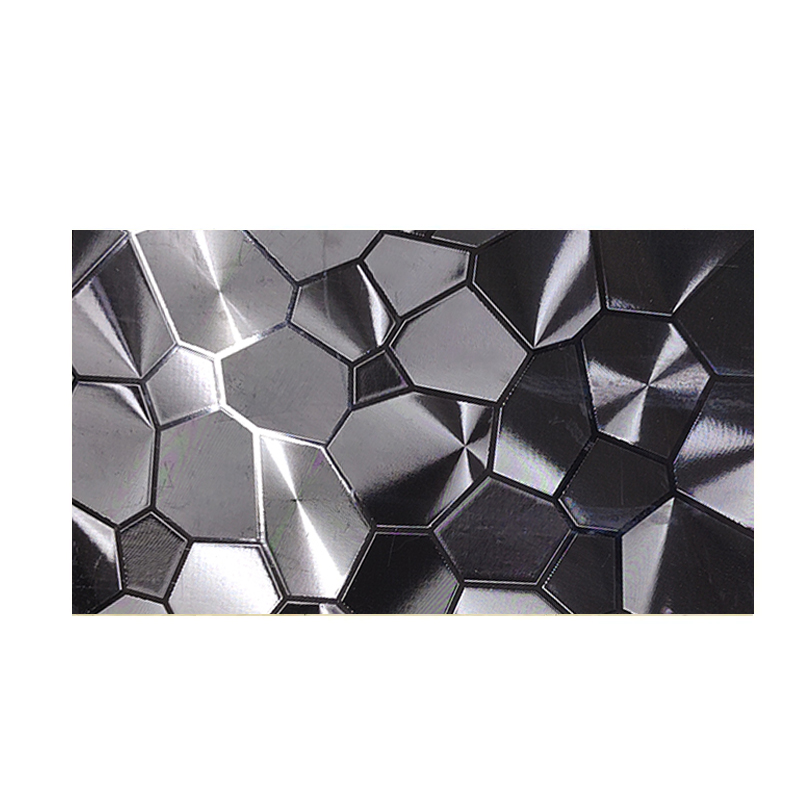

- Decorative Layer: High-resolution printing technology is used to create realistic visuals of hardwood, ceramic, or natural stone.

- Wear Layer: A clear, durable coating (often with a urethane finish) protects the floor from stains, scratches, and fading.

Top 5 Benefits of Choosing SPC Flooring for Your Home

The popularity of SPC stone plastic composite flooring is not without reason. It brings a host of advantages that cater to the practical needs of today's homeowners and designers. From its resistance to moisture to its straightforward installation, the benefits are substantial and impactful.

- 100% Waterproof: The mineral-rich core is impervious to water, making it ideal for moisture-prone areas like basements, kitchens, and bathrooms.

- Extreme Durability: Its rigid construction resists dents from heavy furniture and foot traffic, ensuring a long-lasting beautiful floor.

- Dimensionally Stable: Unlike some flooring that expands and contracts with temperature swings, SPC remains stable, preventing gaps or buckling.

- Comfort and Underfoot Feel: The rigid core provides a solid underfoot feel, and it is often paired with an attached underlayment for added comfort and sound absorption.

- Easy Maintenance: Regular sweeping and occasional damp mopping are all that's needed to keep SPC floors looking new.

SPC vs. Other Vinyl Flooring Types

When considering vinyl flooring, it's crucial to understand the differences between SPC and its close relative, WPC (Wood Plastic Composite). While both are types of rigid core LVT, their core compositions lead to different performance characteristics. The key distinction lies in the core's density and material makeup.

| Feature | SPC Flooring | WPC Flooring |

| Core Composition | Limestone powder & PVC (Denser) | Wood plastic composite & foam (Softer) |

| Density & Indentation Resistance | Higher | Lower |

| Thickness | Generally thinner | Generally thicker |

| Underfoot Comfort | Very solid | Slightly softer, more cushioned |

| Cost | Often more budget-friendly | Typically more expensive |

How to Install SPC Flooring: A DIY-Friendly Guide

One of the most appealing aspects of SPC flooring is its user-friendly installation process. Most SPC stone plastic composite flooring products feature a click-lock system (also known as a floating floor), which allows planks to snap together without the need for glue or nails. This makes it a fantastic project for confident DIYers looking to install SPC flooring themselves and save on labor costs.

- Subfloor Preparation: The subfloor must be clean, dry, and level. Any imperfections can telegraph through the rigid planks.

- Acclimation: While SPC is highly stable, it's still good practice to let the boxes acclimate to the room's temperature and humidity for 24-48 hours.

- Underlayment: Many SPC planks come with a pre-attached underlayment. If not, a separate underlayment roll is recommended for moisture vapor barrier, sound reduction, and minor subfloor smoothing.

- Installation Direction: Plan to install planks parallel to the main light source for the best visual effect.

- Spacing: Maintain a 1/4-inch expansion gap around the entire perimeter of the room to allow for any minimal movement.

SPC Flooring Cost Analysis and Budgeting

Understanding the cost of SPC flooring involves more than just the price per square foot of the planks. A comprehensive budget should account for all materials and potential labor. The overall SPC flooring price is influenced by the thickness of the wear layer, the quality of the design, and the brand.

- Material Cost: SPC flooring itself can range from $2.50 to $5.00 per square foot for most residential grades.

- Additional Materials: Budget for underlayment (if not attached), transition strips, and molding.

- Tools: You may need to purchase or rent a tapping block, pull bar, and a utility knife.

- Labor: Professional installation can add $1.50 to $3.00 per square foot to the total project cost.

Maintaining and Cleaning Your SPC Floors for Longevity

Proper care and cleaning for SPC floors is straightforward but essential for preserving their beauty and extending their lifespan. The robust wear layer does most of the heavy lifting, but a consistent maintenance routine will keep your floors in pristine condition for years to come.

- Daily/Dry Cleaning: Sweep, dust mop, or use a vacuum (with a hard floor setting) to remove abrasive dirt and grit.

- Weekly/Wet Cleaning: Use a damp (not wet) mop with a pH-neutral, vinyl-specific cleaner. Avoid using soap-based detergents or steam mops, which can leave a dulling residue and potentially damage the seams.

- Spill Management: Wipe up spills promptly to prevent potential slipping, though the waterproof nature means no damage will occur.

- Protective Measures: Use felt pads under furniture legs and avoid dragging heavy objects across the floor. Place doormats at entrances to reduce tracked-in debris.

Finding the Best SPC Flooring Suppliers and Products

Navigating the market to find the best SPC flooring suppliers requires a discerning eye. Quality can vary significantly between manufacturers, so it's important to evaluate products based on key performance metrics rather than just aesthetics or price alone.

- Wear Layer Thickness: This is critical for durability. For residential use, look for a wear layer of at least 12 mil to 20 mil. Commercial spaces require 28 mil or higher.

- SPC Core Thickness: A thicker core (e.g., 4mm to 6mm overall) can offer better sound insulation and a more substantial feel.

- Certifications: Look for products with certifications like FloorScore, which indicates low VOC emissions for better indoor air quality.

- Warranty: Reputable suppliers will offer substantial residential and commercial warranties, covering the wear layer for a significant period.

Waterproof, moisture-proof and impact-resistant home decoration SPC flooring Thickness 5 YXSPC22950

FAQ

Can SPC flooring be installed in a bathroom or basement?

Absolutely. This is one of the primary advantages of SPC stone plastic composite flooring. Its 100% waterproof core makes it an excellent choice for high-moisture environments like bathrooms, basements, kitchens, and laundry rooms. Unlike traditional hardwood or laminate, SPC will not warp, swell, or develop mold when exposed to moisture, provided it is installed correctly with proper subfloor preparation.

Is SPC flooring considered environmentally friendly?

SPC flooring has several eco-friendly attributes. Its core contains natural limestone, an abundant resource. Many manufacturers also produce SPC floors with high percentages of recycled content. Furthermore, certifications like FloorScore ensure that the products meet strict standards for low chemical emissions, contributing to healthier indoor air quality. When comparing flooring options, SPC often presents a sustainable choice, especially when sourced from suppliers committed to green manufacturing practices.

How does SPC flooring handle underfloor heating?

SPC flooring is generally compatible with most radiant floor heating systems due to its excellent thermal conductivity and dimensional stability. The dense stone-plastic core efficiently transfers heat, making the system more effective. However, it is imperative to consult both the flooring manufacturer's and the heating system manufacturer's guidelines. There will be specific recommendations regarding maximum surface temperature (usually not exceeding 85°F or 27°C) to prevent damage to the flooring.

What is the typical lifespan of SPC flooring?

The lifespan of SPC stone plastic composite flooring is directly tied to the quality of its wear layer and the level of foot traffic it endures. In a typical residential setting, a high-quality SPC floor with a 20-mil wear layer can easily last 15 to 25 years. For commercial applications with heavier use, a product with a thicker commercial-grade wear layer (28 mil+) is recommended to achieve a similar lifespan. Proper maintenance, as outlined in this guide, is crucial for reaching its maximum potential longevity.

Can you replace a single plank if it gets damaged?

Yes, replacing a single plank in a floating SPC flooring installation is possible, though it can be a delicate process. Since the planks are interlocked, you typically need to disassemble the floor from the wall up to the damaged plank, replace it, and then reinstall the rows. Some professional installers use specialized tools to cut out the tongue of the damaged plank and glue a new one in place, minimizing the need for full disassembly. It's always wise to purchase extra boxes of flooring at the time of installation for this exact purpose.