+86-18367343973

- 1 What Are Flexible Stone Veneer Sheets?

- 2 Best Adhesive for Flexible Stone Veneer Sheets

- 3 How to Cut Flexible Stone Veneer Sheets Without Cracking

- 4 Flexible Stone Veneer Sheets vs Traditional Stone Cladding

- 5 Waterproofing Flexible Stone Veneer Sheets for Outdoor Use

- 6 DIY Installation Tips for Flexible Stone Veneer Sheets

What Are Flexible Stone Veneer Sheets?

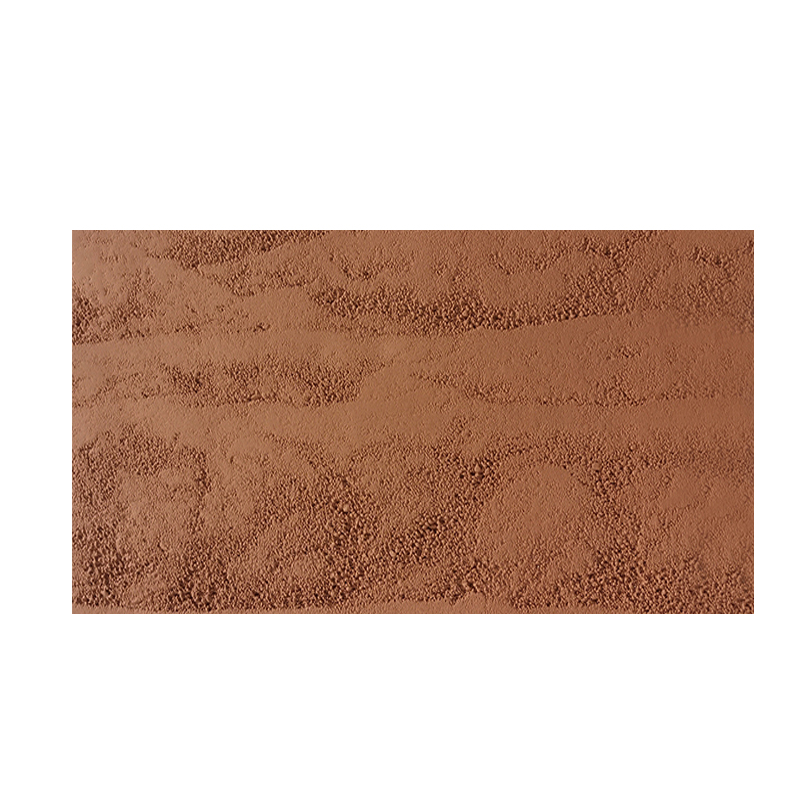

Flexible stone veneer sheets are ultra-thin, lightweight panels made from natural stone composites. Unlike traditional stone cladding, these sheets can bend and adapt to curved surfaces, making them ideal for both interior and exterior applications. Their versatility and ease of installation have made them a popular choice for modern architecture and DIY projects.

Flexible Stone Veneer Sheet - Weatherproof & Lightweight Exterior Cladding for Walls YXCL-REA7

Key Features of Flexible Stone Veneer

- Thickness ranges from 1mm to 3mm, allowing for seamless bending

- Available in various natural stone patterns including slate, quartzite, and marble

- UV-resistant and weatherproof for outdoor use

- Up to 70% lighter than traditional stone cladding

Best Adhesive for Flexible Stone Veneer Sheets

Choosing the right adhesive is critical for ensuring the longevity and stability of your flexible stone veneer installation. Unlike rigid stone panels, flexible sheets require specialized adhesives that accommodate slight movements while maintaining strong bonding.

Types of Adhesives Compared

Here’s a comparison of common adhesive types used with flexible stone veneer sheets:

| Adhesive Type | Best For | Curing Time | Water Resistance |

|---|---|---|---|

| Polyurethane-based | Exterior applications | 24-48 hours | Excellent |

| Acrylic-modified | Interior walls | 12-24 hours | Good |

| Epoxy-based | High-moisture areas | 6-12 hours | Superior |

Application Tips

- Always prepare the surface by cleaning and priming

- Use notched trowels for even adhesive distribution

- Allow proper curing time before grouting or sealing

How to Cut Flexible Stone Veneer Sheets Without Cracking

Precision cutting is essential when working with flexible stone veneer sheets to maintain their structural integrity. Traditional stone-cutting methods often cause chipping or fractures in these thin materials.

Recommended Cutting Tools

- Diamond-tipped scoring knives for straight cuts

- Rotary tools with carbide bits for intricate shapes

- Water-jet cutters for professional-grade precision

Step-by-Step Cutting Process

- Mark cutting lines with chalk or painter's tape

- Secure the sheet on a stable, flat surface

- Make multiple light passes rather than one deep cut

- Support both sides of the cut to prevent snapping

Flexible Stone Veneer Sheets vs Traditional Stone Cladding

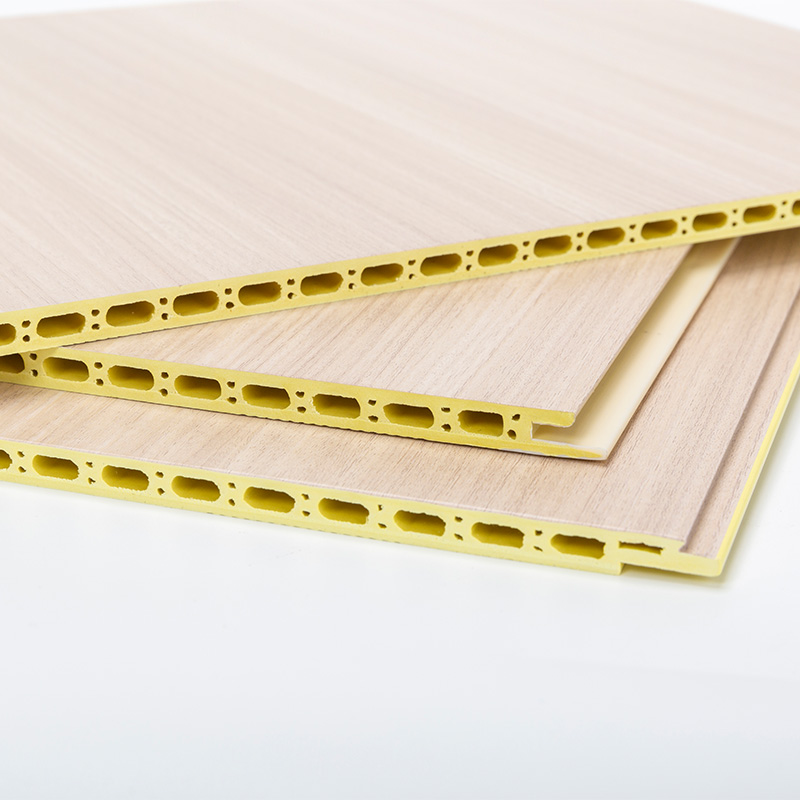

When comparing flexible stone veneer sheets to conventional stone cladding, several key differences emerge that affect installation, cost, and performance.

Comparative Analysis

| Feature | Flexible Veneer | Traditional Cladding |

|---|---|---|

| Weight | 0.5-1.5 kg/sqft | 3-6 kg/sqft |

| Installation Time | 30-50% faster | Requires more labor |

| Cost | 40-60% lower | Higher material costs |

When to Choose Each Option

- Flexible veneer excels in retrofit projects and curved surfaces

- Traditional cladding may be preferable for historical restoration

Waterproofing Flexible Stone Veneer Sheets for Outdoor Use

While flexible stone veneer sheets are naturally durable, proper waterproofing extends their lifespan in exterior applications significantly.

Waterproofing Methods Compared

- Penetrating sealers: Allow vapor transmission while repelling water

- Film-forming sealers: Create a protective surface layer

- Hybrid systems: Combine both approaches for maximum protection

Maintenance Considerations

- Reapply sealant every 3-5 years depending on climate

- Clean with pH-neutral cleaners to avoid damaging the surface

- Inspect annually for cracks or sealant deterioration

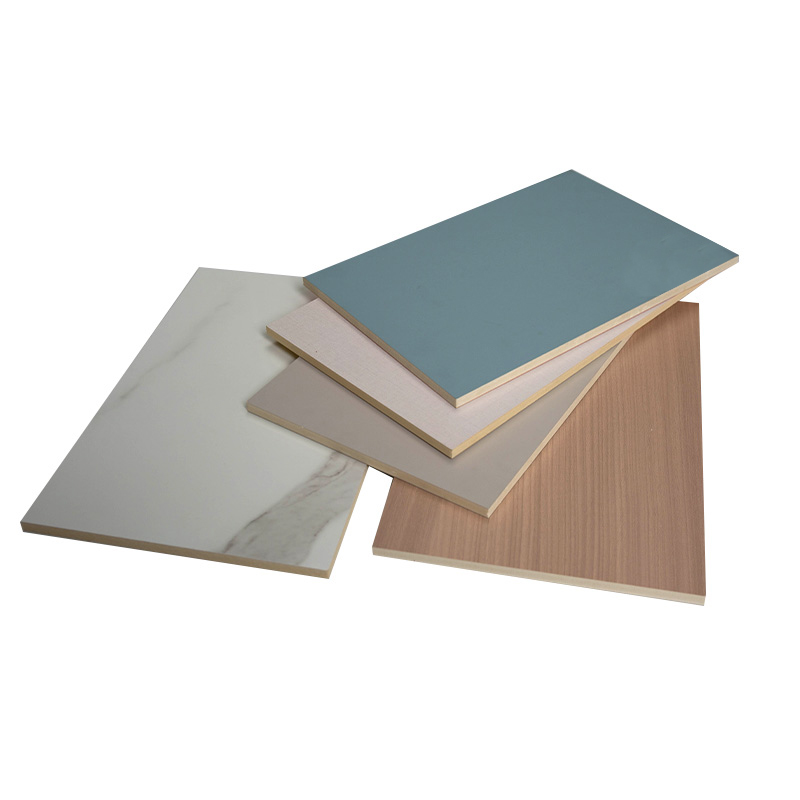

DIY Installation Tips for Flexible Stone Veneer Sheets

Installing flexible stone veneer sheets as a DIY project can save significant costs while achieving professional-looking results when proper techniques are followed.

Essential Tools Checklist

- Notched trowel (1/4" x 3/8" notch recommended)

- Rubber grout float for finishing

- Laser level for alignment

Common Mistakes to Avoid

- Applying adhesive too thickly, causing uneven surfaces

- Failing to stagger seams for a natural look

- Not allowing proper expansion gaps in outdoor installations