+86-18367343973

- 1 The Installation Phase: Labor, Time, and Substrate Requirements

- 2 Long-term Maintenance and Hygiene Analysis

- 3 Lifecycle Cost Assessment for Large-Scale Construction

- 4 Technological Innovation in Modern Wall Systems

- 5 Frequently Asked Questions (FAQ)

- 6 Technical Data Sheet: High-Performance Wood Veneer & Flexible PVC Wall Systems

- 7 Industry References

In the modern architectural landscape, selecting interior surfacing materials requires a rigorous analysis of lifecycle costs and operational efficiency. While traditional ceramic and stone tiling have long been the industry standard, the emergence of flexible pvc wall panels has redefined expectations for both residential and large-scale commercial projects. Haining Yunxi New Material Technology Co., Ltd., a leader in the independent research and development of advanced wall systems, provides high-performance alternatives designed to meet the aesthetic demands of home decoration while satisfying the strict durability requirements of professional construction.

The Installation Phase: Labor, Time, and Substrate Requirements

Traditional tiling is a labor-intensive process involving wet-trade skills, including adhesive application, precision cutting, and grouting, which often leads to significant project downtime. Conversely, waterproof pvc wall cladding utilizes a dry-installation method that allows for rapid deployment over existing surfaces, including uneven substrates. This flexibility significantly reduces the total man-hours required for project completion, making it a superior choice for "fast-track" renovations.

The following table illustrates the technical differences in the installation workflow between these two systems:

| Process Metric | Traditional Ceramic Tiling | Flexible PVC Wall Panels |

| Substrate Preparation | Must be perfectly level and primed | Tolerance for minor irregularities |

| Installation Speed | Slow (15-20 m² per day per person) | Fast (50-80 m² per day per person) |

| Curing Time | 24-48 hours (Adhesive & Grout) | Instant (Mechanical or Adhesive) |

| Specialist Skills | High (Professional Tiler required) | Moderate (Carpentry-based skills) |

Long-term Maintenance and Hygiene Analysis

From a maintenance engineering perspective, the primary failure point of traditional tiling is the grout line, which is porous and susceptible to mold growth and chemical degradation. Commercial grade pvc wall panels feature a non-porous, monolithic surface that eliminates these vulnerabilities. For healthcare and hospitality environments, the ability to maintain a sterile surface with minimal chemical intervention is a critical operational advantage.

Surface Stability and Chemical Resistance

Traditional tiles offer high scratch resistance but are brittle and prone to cracking under structural movement. In contrast, impact resistant flexible pvc panels absorb mechanical energy without fracturing, ensuring that the wall remains intact even in high-traffic corridors or seismic zones.

| Maintenance Factor | Traditional Tiling | Flexible PVC Wall Panels |

| Grout Integrity | Prone to staining and cracking | None (Seamless or tongue-and-groove) |

| Cleaning Protocol | Requires scrubbing and acid cleaners | Simple wipe-down with mild detergent |

| Moisture Barrier | Dependent on secondary membrane | Inherent (100% waterproof core) |

| Repairability | Difficult (Requires tile removal) | Easy (Individual panel replacement) |

Lifecycle Cost Assessment for Large-Scale Construction

While the initial material cost of decorative interior pvc wall boards may vary, the "Total Cost of Ownership" (TCO) is lower due to reduced maintenance and faster renovation cycles. Haining Yunxi New Material Technology Co., Ltd. has focused on technological innovation to create wood veneer wall panels and flooring systems that simulate high-end materials while providing the cost-benefit ratio required by modern developers. Our product system is designed to meet various styles without the heavy weight and fragile nature of stone or ceramic.

Material Weight and Logistics

The density of PVC panels is significantly lower than that of ceramic, which reduces transportation costs and structural load on the building's frame—a key consideration for high-rise developments.

- Logistics Efficiency: PVC panels are lightweight, allowing for more square footage per shipping container.

- Waste Reduction: Precision extrusion of textured flexible pvc wall sheets results in minimal on-site waste compared to tile breakage.

- Thermal Stability: Advanced PVC formulations maintain dimensional stability across a wider temperature range than early-generation plastic panels.

Technological Innovation in Modern Wall Systems

Haining Yunxi New Material Technology Co., Ltd. continues to lead the industry through team management and brand building, ensuring that our flexible pvc wall panels are not just aesthetic upgrades but engineered solutions. By focusing on the independent research and development of wood veneer and modern wall systems, we provide consumers and contractors with a rich product system that bridges the gap between luxury design and industrial durability.

Frequently Asked Questions (FAQ)

- Q1: Are flexible PVC wall panels suitable for wet areas like commercial showers?

A: Yes, they are inherently waterproof and, unlike tile, do not rely on grout, which prevents water from seeping behind the substrate. - Q2: How do PVC panels perform in terms of fire safety?

A: High-quality PVC panels are engineered with fire-retardant additives to meet international safety standards (such as Class B1), ensuring they are suitable for public building codes. - Q3: Can these panels be installed over existing tiles?

A: Absolutely. Their flexible nature and low profile make them ideal for "over-tiling" projects, saving the cost and mess of demolition. - Q4: Do PVC wall panels fade or yellow over time?

A: Premium panels are treated with UV-stabilized coatings and high-definition decorative layers that maintain color fastness even in well-lit interior environments. - Q5: What is the expected lifespan of a professional-grade PVC panel?

A: When properly installed and maintained, these panels can last 15-20 years, often outlasting the aesthetic relevance of the interior design they serve.

Technical Data Sheet: High-Performance Wood Veneer & Flexible PVC Wall Systems

This document specifies the mechanical, thermal, and chemical properties of the flexible pvc wall panels and wood veneer systems engineered by Haining Yunxi New Material Technology Co., Ltd. Our focus on independent R&D ensures that these commercial grade pvc wall panels provide a high-durability alternative to stone and ceramic cladding for diverse construction projects.

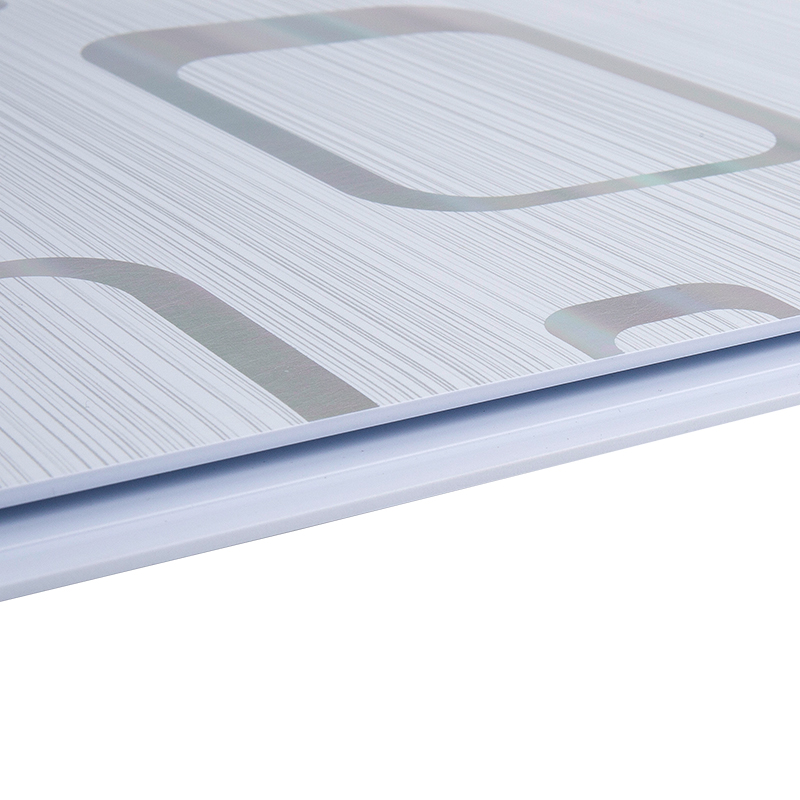

1. Material Composition & Structural Integrity

Utilizing high-purity virgin PVC resin and advanced stabilizers, our panels achieve a superior balance of flexibility and rigidity. This allows for impact resistant flexible pvc panels that can be cold-bent around architectural curves without stress whitening or fracturing.

| Technical Property | Standard / Test Method | Performance Value |

| Core Material | High-Density Rigid/Flexible PVC Composite | Virgin Grade (Non-recycled) |

| Surface Coating | UV-Cured Anti-Scratch Layer | Standard 3H - 5H Hardness |

| Density | ASTM D792 | 1.4 - 1.6 g/cm³ |

| Flexural Strength | ISO 178 | ≥ 40 MPa |

2. Environmental and Safety Compliance

Safety and indoor air quality are central to our brand building. Our waterproof pvc wall cladding is formulated to be eco-friendly, meeting the stringent requirements for modern home decoration and public infrastructure.

- Fire Classification: Rated B1 (Flame Retardant) according to GB 8624 / EN 13501-1.

- Formaldehyde Emission: E0 Grade (≤ 0.05 mg/m³), ensuring safety for residential and healthcare facilities.

- Chemical Resistance: Resistant to diluted acids, alkalis, and common industrial detergents (Grade 5).

- VOC Levels: Compliant with international green building standards.

3. Aesthetic & Physical Performance

The decorative interior pvc wall boards produced by Haining Yunxi feature high-definition wood veneer finishes. Our technological innovation allows for a deep textured flexible pvc wall sheets finish that replicates natural timber without the maintenance overhead of real wood.

| Performance Metric | Traditional Wood Veneer | Yunxi Flexible PVC Veneer |

| Moisture Absorption | High (Prone to rot/warp) | Zero (< 0.1% absorption) |

| Color Fastness | Fades under UV exposure | Grade 7/8 (High UV stability) |

| Installation Radius | Inflexible / Brittle | Min. Radius 300mm (Cold-bend) |

| Anti-Bacterial | Low (Porous surface) | High (Non-porous, ISO 22196 compliant) |

4. Dimension & Logistics Specifications

To meet the needs of various types of construction projects, we offer optimized dimensions for rapid installation and cost-effective shipping.

- Standard Thickness: 3mm, 5mm, 8mm, or customized for commercial grade pvc wall panels.

- Standard Width: 1220mm (Typical) or custom extrusion profiles.

- Length: 2440mm, 2800mm, or continuous rolls for ultra-flexible variants.

- Packaging: Protective PE film on the decorative face, packed in reinforced export pallets.

Through continuous development in team management and technological innovation, Haining Yunxi New Material Technology Co., Ltd. ensures that every panel delivered fully meets the high standards favored by consumers and professional builders worldwide.

Industry References

- ISO 10545: International Standard for testing ceramic tiles (Physical and chemical properties).

- ASTM D1784: Standard Specification for Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated Poly(Vinyl Chloride) (CPVC) Compounds.

- Journal of Building Engineering: Comparative analysis of the environmental impact and cost-efficiency of plastic vs. ceramic cladding.

- European Standard EN 13245: Plastics - Unplasticized poly(vinyl chloride) (PVC-U) profiles for building applications.