+86-18367343973

Interior WPC Wall Panel has become a preferred choice for B2B buyers seeking durable, eco-friendly, and visually appealing interior solutions. Ensuring the quality and performance of these panels is critical for long-term success in commercial and residential projects.

Understanding WPC Wall Panels

What Are WPC Wall Panels?

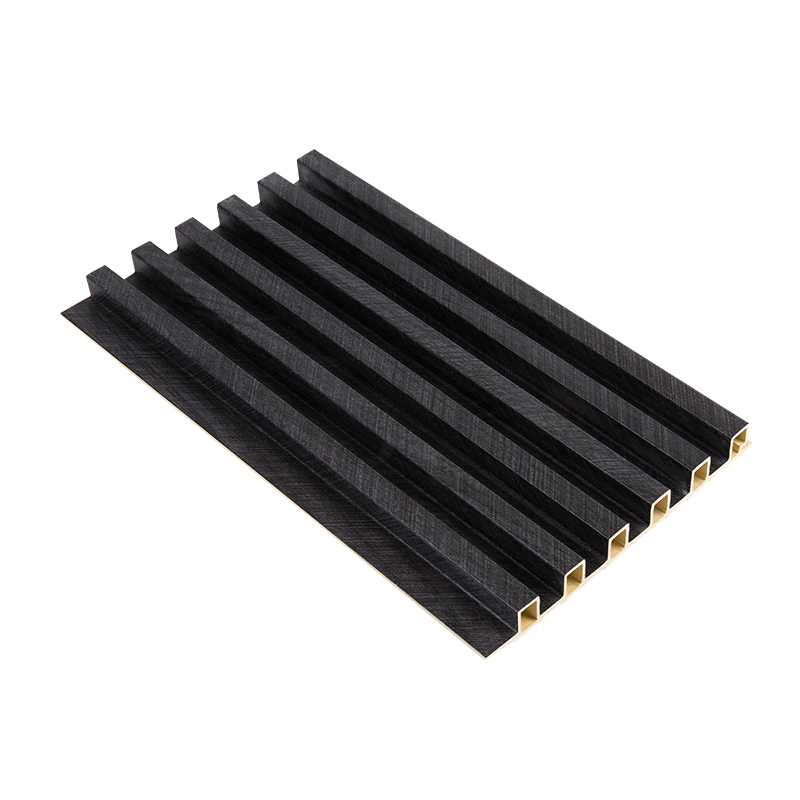

WPC wall panels are engineered materials combining wood fibers and plastic polymers. This mix creates panels that:

- Maintain the natural look of wood

- Are resistant to moisture and insects

- Require minimal maintenance

- Provide long-term durability in various environments

Applications in Interior Design

WPC wall panels are highly versatile and can be used in:

- Commercial spaces like hotels, restaurants, and retail stores

- Office interiors for partitions, feature walls, and ceilings

- Residential interiors including living rooms, bathrooms, and kitchens

Compared to traditional wood panels, WPC wall panels offer improved moisture resistance, less warping, and reduced maintenance costs, making them ideal for high-traffic or humid areas.

Key Quality Assurance Factors

Material Composition

High-quality WPC wall panels depend on a proper ratio of wood fibers to plastic. Key points include:

- Wood content: 50–70% for natural appearance

- Plastic content: 30–50% to improve durability

- Additives: UV stabilizers, fire retardants, and anti-fungal agents

Panels with low wood content may look artificial, while those with too much wood may warp or crack in humid conditions.

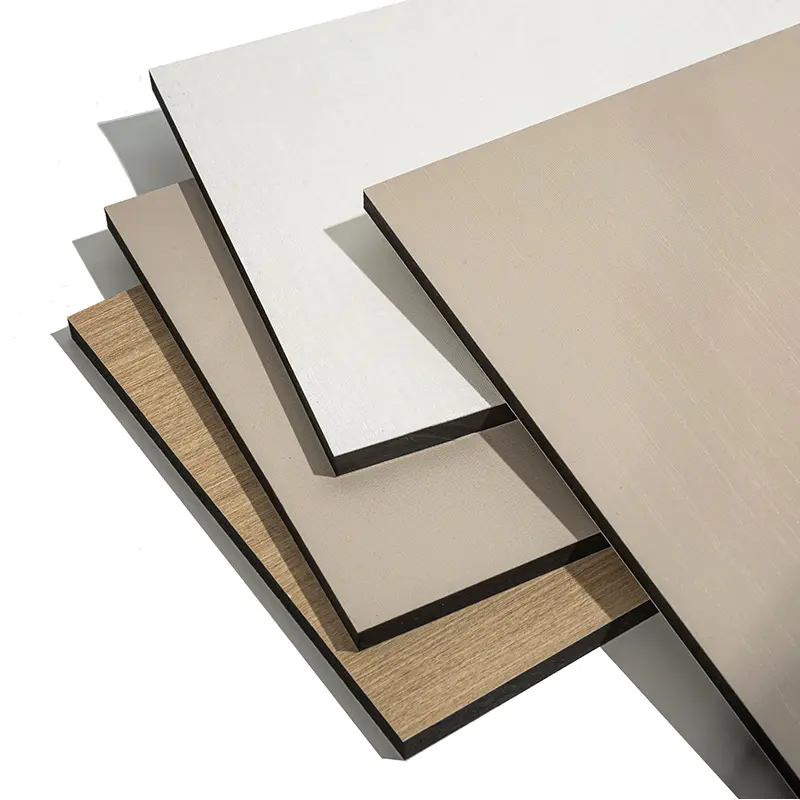

Surface Finish and Texture

The finish directly affects aesthetics and usability. Quality indicators include:

- Uniform texture without bubbles or cracks

- Resistance to scratches and stains

- Compatibility with paints or varnishes for custom finishes

Comparison table:

| Feature | High-quality WPC | Low-quality WPC |

|---|---|---|

| Surface uniformity | Smooth, consistent | Uneven, rough |

| Scratch resistance | High | Low |

| Paint/finish compatibility | Excellent | Poor |

Environmental Resistance

Environmental resistance ensures panels last longer in different climates:

- Waterproofing for bathrooms, kitchens, and outdoor areas

- Moisture resistance to prevent swelling or mold

- UV resistance to avoid fading in sunlight

- Fire retardant properties for safety compliance

Evaluating WPC Wall Panel Suppliers

Supplier Credentials

- ISO or CE certification for production standards

- Compliance with environmental regulations

- Positive reviews from previous B2B clients

Product Range and Customization

Top suppliers provide:

- Various designs, colors, and textures

- Custom dimensions and patterns

- Solutions for both commercial and residential projects

Pricing and Bulk Orders

- Competitive pricing for large-scale projects

- Discounts or negotiation options for bulk orders

- Transparent shipping and delivery terms

Case Studies and Real-World Applications

Successful installations demonstrate the versatility of WPC wall panels:

- Office feature walls with eco-friendly and durable panels

- Restaurants and hotels using waterproof panels for high-moisture areas

- Residential interiors with customizable designs for modern aesthetics

Parameters of High-Quality WPC Wall Panels

| Parameter | Recommended Value |

| Wood fiber content | 50–70% |

| Plastic content | 30–50% |

| Thickness | 8–12 mm for walls, 12–16 mm for partitions |

| Water absorption | ≤3% |

| Surface hardness | ≥3H |

| Fire rating | B1 or higher |

Conclusion

Ensuring the quality and performance of Interior WPC Wall Panel requires understanding material composition, surface finish, environmental resistance, and supplier reliability. By carefully evaluating these factors, B2B buyers can achieve lasting, high-quality installations.

FAQ

1. What makes WPC wall panels more durable than traditional wood panels?

WPC panels combine wood fibers with plastic, which improves resistance to moisture, insects, and UV exposure. Unlike natural wood, they do not warp easily and require less maintenance.

2. Can Haining Yunxi New Material Technology Co., Ltd. provide customized WPC panels for commercial projects?

Yes. Haining Yunxi New Material Technology Co., Ltd. has long been focusing on the independent research and development and production of wood veneer wall panels and flooring. They offer a rich product system that fully meets the needs of various styles of home decoration and different types of construction projects, earning the trust of many B2B clients.

3. Are the WPC wall panels from Haining Yunxi New Material Technology Co., Ltd. eco-friendly?

Absolutely. As an all-round development modern enterprise, Haining Yunxi New Material Technology Co., Ltd. ensures their panels are environmentally friendly, and in recent years, the company has advanced in technological innovation, brand building, and team management, attracting attention from the industry.

YXWPC1228 8MM Thickness WPC Wood Veneer Decoration Paint-Free Board Solid Wood Wall Board