+86-18367343973

I. Basic Knowledge of SPC Flooring

SPC flooring, short for Stone Plastic Composite flooring, gets its name from its unique stone-plastic composite structure. It's a new type of environmentally friendly flooring material that's gaining popularity worldwide. With its outstanding performance, SPC flooring shows broad application prospects in both modern home SPC flooring and commercial SPC flooring sectors.

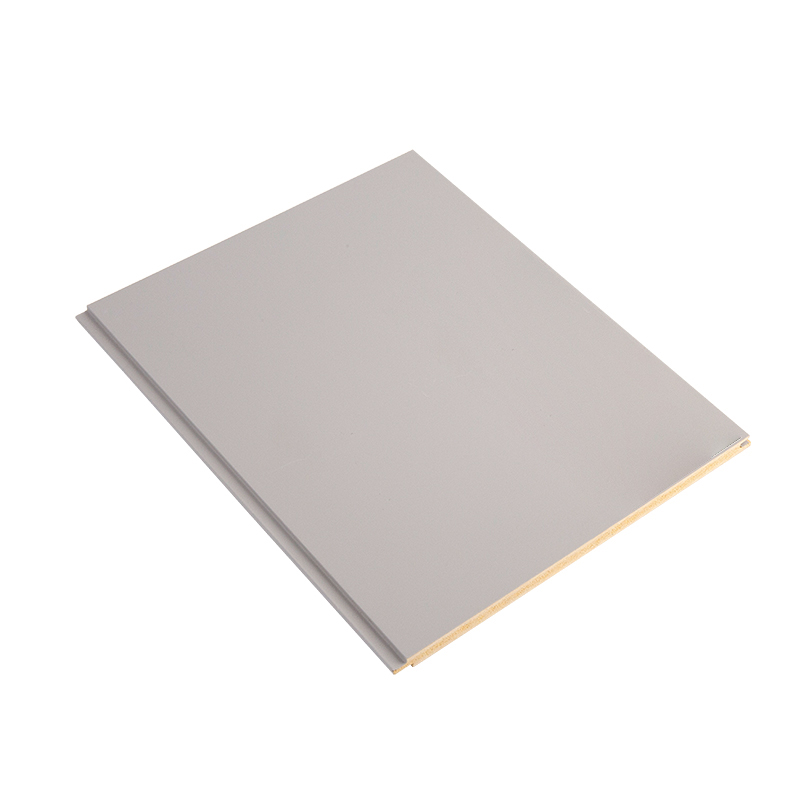

Waterproof, moisture-proof and impact-resistant home decoration SPC flooring Thickness 5 YXSPC22950

1.1 Structure and Composition of SPC Flooring

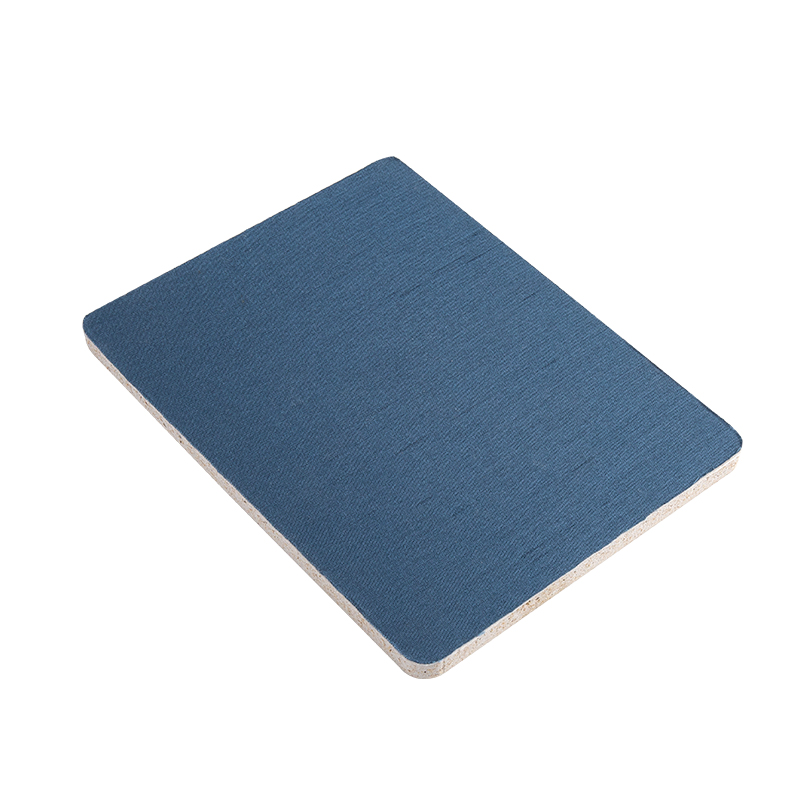

SPC flooring's excellent performance comes from its multi-layered composite structure. Typically, SPC flooring consists of the following four layers from top to bottom:

- Wear Layer: Located at the very top of the flooring, this transparent and highly wear-resistant layer is crucial for protecting the floor from scratches and abrasions. Its thickness directly impacts the flooring's durability.

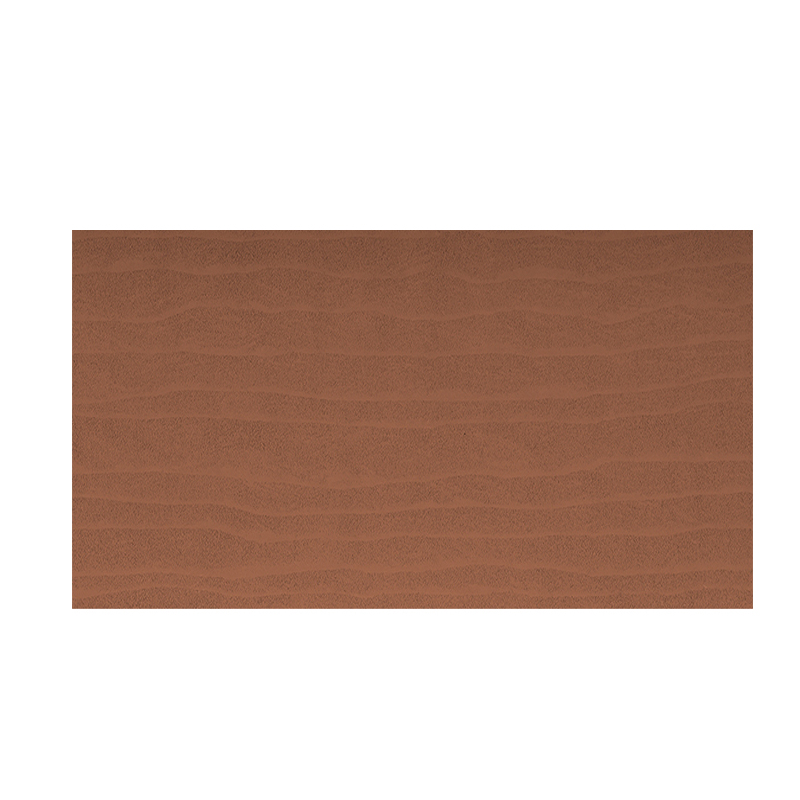

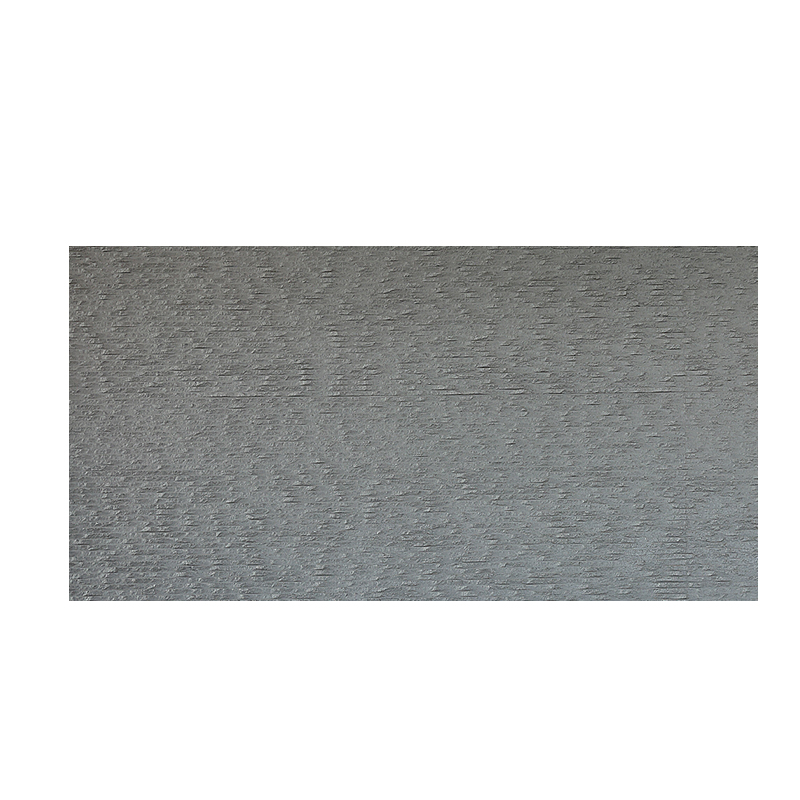

- Decor Layer: Situated beneath the wear layer, this layer uses high-definition printing technology to display various beautiful patterns like wood grain, stone texture, and carpet designs, giving SPC flooring a rich visual appeal.

- SPC Core Layer: This is the core of SPC flooring, made from a mix of stone powder and polymer resins, formed by high-temperature extrusion. It gives the flooring excellent stability and waterproof properties.

- Underlayment: Usually an IXPE or EVA pad layer, its main function is to provide better foot comfort, sound absorption, and some moisture-proof properties.

II. SPC Flooring vs. LVT Flooring vs. WPC Flooring

Within the resilient flooring family, SPC flooring is often compared to LVT flooring (Luxury Vinyl Tile) and WPC flooring (Wood Plastic Composite). Understanding their similarities and differences helps us choose the most suitable flooring material.

| Feature | SPC Flooring | LVT Flooring | WPC Flooring |

| Main Components | Stone powder + PVC | PVC | Wood powder + PVC |

| Stability | Excellent, resistant to thermal expansion/contraction | Good, but may deform with large temperature changes | Good |

| Waterproof | Excellent, completely waterproof | Excellent, completely waterproof | Excellent, completely waterproof |

| Thickness | Thinner (generally 4-6mm) | Thinner (generally 2-3mm) | Thicker (generally 5-8mm) |

| Underfoot Feel | Harder | Softer, good elasticity | Softer, good elasticity |

| Installation | Primarily click-lock | Mostly glue-down or click-lock | Primarily click-lock |

| Price | Moderate to high | Moderate | Higher |

| Application | High-traffic area SPC flooring, radiant heat, moist environments | Homes, commercial, not ideal for large temp swings | Homes, commercial, where foot comfort is prioritized, often replaces hardwood |

III. Advantages and Disadvantages of SPC Flooring

SPC flooring holds a strong position in the market due to its unique advantages, but it also has some drawbacks.

3.1 Advantages

- Exceptional Waterproof Performance: The SPC flooring core is completely waterproof, making it an ideal choice for SPC flooring for wet areas like kitchens and bathrooms, without worrying about moisture damage, warping, or mold.

- Superior Wear Resistance: The surface wear layer effectively resists scratches and abrasions, suitable for both residential and commercial spaces, especially high-traffic area SPC flooring, maintaining its aesthetic appeal for a long time.

- Environmentally Friendly: SPC flooring contains no harmful substances like formaldehyde or benzene and has passed multiple environmental certifications, making it a truly eco-friendly building material.

- Excellent Stability: Its unique stone-plastic composite structure makes it resistant to warping and cracking even in environments with significant temperature and humidity changes.

- Easy Installation: Most SPC flooring features a click-lock design, allowing for glue-free, quick, and easy installation, making it suitable for DIY.

- Radiant Heat Compatibility: It has good thermal conductivity and strong stability, making it very suitable for installation in rooms with radiant heating systems, making it an ideal radiant heat specific SPC flooring.

3.2 Disadvantages

- Harder Underfoot Feel: Compared to hardwood or WPC flooring, SPC flooring has a relatively harder underfoot feel. If comfort is a high priority, a thicker underlayment might be needed.

- Slightly Higher Price: While it offers advantages over traditional hardwood, the initial investment for SPC flooring might be slightly higher compared to some low-end laminate flooring options.

- Not Suitable for Outdoors: Despite being waterproof and wear-resistant, standard SPC flooring is not designed for outdoor environments directly exposed to sunlight and extreme weather. Outdoor SPC flooring requires special formulations and treatments.

IV. How to Choose SPC Flooring

When selecting SPC flooring, besides considering price and appearance, it's crucial to pay attention to its performance indicators and suitability for different scenarios to ensure you choose the product that best meets your needs.

4.1 Application Scenario Analysis

- Residential Use: Home SPC flooring is generally suitable for all indoor spaces like living rooms, bedrooms, kitchens, and bathrooms, especially ideal for homes with pets or children.

- Commercial Use: Commercial SPC flooring and engineering SPC flooring are often used in offices, hotels, shops, schools, and hospitals due to their durability, ease of cleaning, and waterproof properties, meeting the demands of high foot traffic.

- Radiant Heat Compatibility: As mentioned earlier, SPC flooring is an excellent choice for radiant heat specific SPC flooring, effectively conducting heat.

4.2 Key Purchase Indicators

- Thickness: SPC flooring thickness typically ranges from 3.5mm to 6mm. Generally, thicker SPC flooring offers better stability and underfoot feel, but the price will also be higher.

- Wear Layer Rating: The wear layer rating is an important indicator of flooring durability, usually expressed as an AC rating (AC1-AC5). For home use, AC3 or AC4 is generally sufficient, while high-traffic area SPC flooring should opt for AC4 or AC5.

- Environmental Certifications: When purchasing, always confirm that the product has passed international environmental certifications, such as CE, Floorscore, etc., to ensure it is free of harmful substances like formaldehyde.

- Click-Lock Quality: The click-lock system is crucial for connecting the planks. High-quality click-locks ensure the flooring is securely and evenly installed, preventing gaps later on.

- Customization and Size: Besides standard sizes, custom SPC flooring and special size SPC flooring are also available on the market, allowing you to choose based on your design requirements.

4.3 Brand and Price Reference

The SPC flooring market has numerous brands, including both internationally renowned and excellent domestic manufacturers. The price range is influenced by factors like brand, thickness, wear layer rating, and additional features (like integrated underlayment), ranging from tens to hundreds of yuan per square meter. It's advisable to compare multiple options and choose brands with good reputation and reliable after-sales service.

V. SPC Flooring Installation Guide

Correct installation is key to ensuring the performance and longevity of SPC flooring.

5.1 Pre-Installation Preparation

- Subfloor Flatness: Ensure the installation subfloor is flat, solid, dry, and clean. If the subfloor is uneven, self-leveling treatment may be needed first.

- Moisture Protection: Although SPC flooring itself is waterproof, when installing on a damp subfloor, it's still recommended to implement moisture protection, such as laying a vapor barrier, especially for SPC flooring for wet areas.

- Material Acclimation: Flooring materials should be placed in the installation environment 24-48 hours prior to installation to allow them to acclimate to indoor temperature and humidity.

5.2 Installation Methods

- Click-Lock System: This is the most common installation method for SPC flooring, where planks interlock without glue, making installation quick and suitable for DIY.

- Glue-Down: A few SPC flooring products also support glue-down installation, but this is typically used for commercial projects or specific situations requiring higher stability, and is not recommended for personal DIY.

5.3 Common Installation Problems and Solutions

- Gaps: May be caused by incomplete click-lock engagement or an uneven subfloor. Ensure click-locks are fully engaged during installation and prepare the subfloor properly beforehand.

- Cupping/Buckling: Usually caused by not leaving sufficient expansion gaps between the flooring and walls. An 8-10mm expansion gap should be left around the perimeter during installation.

VI. Performance Analysis of SPC Flooring

A deeper understanding of SPC flooring's performance indicators helps us more comprehensively evaluate its suitability.

6.1 Waterproof Performance

The SPC core layer of SPC flooring is completely waterproof, meaning water won't penetrate the flooring and cause swelling or deformation. This makes it an excellent choice for SPC flooring for wet areas like kitchens, bathrooms, and laundry rooms, serving as a superior alternative to tiles or traditional wood flooring.

6.2 Wear Resistance and Lifespan

The wear resistance of SPC flooring depends on the thickness and rating of its surface wear layer. Wear resistance is usually indicated by an AC rating (e.g., AC3, AC4, AC5), with higher numbers signifying better wear resistance. AC3 is suitable for general home use, while AC4 and AC5 are recommended for high-traffic commercial areas or high-traffic area SPC flooring. Its designed lifespan can range from 10-25 years, or even longer.

6.3 Environmental Friendliness

SPC flooring does not use glue in its manufacturing process, thus it contains no harmful substances like formaldehyde or benzene. It complies with strict international environmental standards, such as European CE certification and American Floorscore certification, making it a truly green and environmentally friendly building material that is harmless to human health.

6.4 Sound Insulation and Underfoot Feel

Compared to hardwood flooring, SPC flooring's underfoot feel is slightly harder. However, by adding an IXPE or EVA underlayment, both underfoot comfort and sound insulation can be significantly improved. Compared to laminate flooring, SPC flooring performs better in terms of sound insulation and underfoot feel, and its stone-plastic core provides a more stable sensation.

VII. Maintenance and Care of SPC Flooring

Proper maintenance and care can significantly extend the lifespan of SPC flooring, keeping it looking new.

7.1 Daily Cleaning Methods

- Vacuuming: Regularly vacuum the floor surface to remove dust and debris.

- Mopping Precautions: You can use a slightly damp mop for cleaning, but avoid using an overly wet mop, and never flood the floor with water. Use a neutral cleaner and avoid strong acidic or alkaline detergents.

7.2 Common Problem Handling

- Scratches: Minor scratches can be treated with a special repair crayon or filler. Severe scratches might require replacing the damaged plank.

- Stain Removal: For ordinary stains, simply wipe with a damp cloth promptly. For stubborn stains, use a small amount of diluted neutral cleaner, then immediately wipe dry.

7.3 Tips for Extending Lifespan

- Avoid Direct Sunlight: Long-term strong direct sunlight can cause changes in flooring color; it's advisable to use curtains for shading.

- Use Protective Pads: Place protective pads under furniture legs to prevent scratching the floor.

- Regular Cleaning: Keep the floor clean to avoid abrasive materials like grit from constantly rubbing against the surface.

SPC flooring is becoming a new favorite in the flooring market due to its excellent performance and environmental friendliness. Whether for home renovation, commercial projects, or specialized applications, SPC flooring offers a reliable and aesthetically pleasing flooring solution. Do you now have a more comprehensive understanding of SPC flooring?