+86-18367343973

1. Core Advantages of SPC Flooring

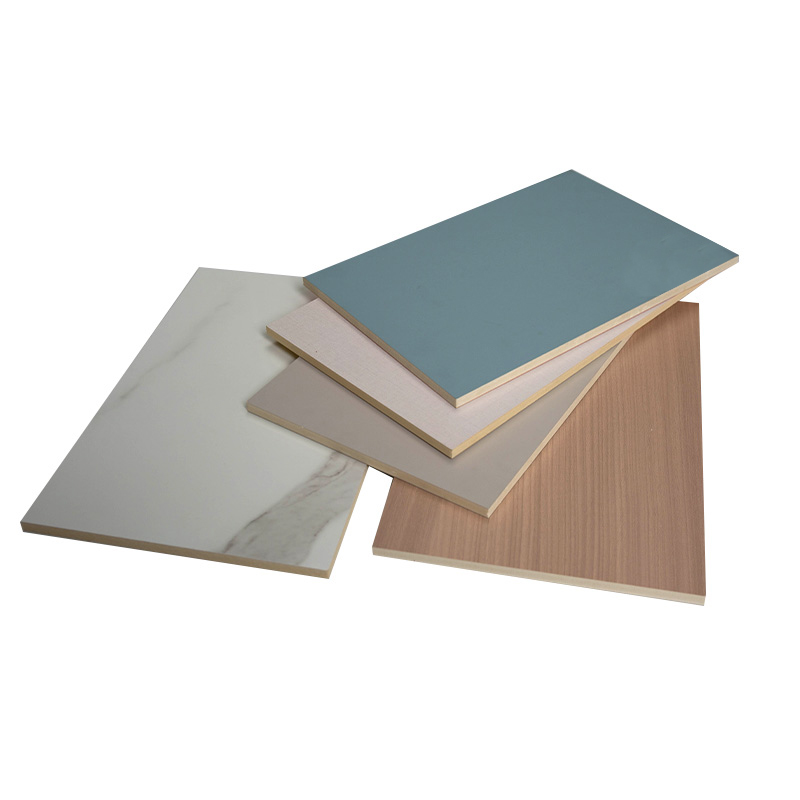

SPC (Stone Plastic Composite) flooring, also known as stone-plastic composite flooring, has become a popular choice for indoor floor decoration in recent years. Its core advantages mainly include waterproof performance, durability, stability, and comfort.

1.1 Waterproof Performance

The core structure of SPC flooring is a composite of stone powder and polyvinyl chloride (PVC), providing 100% waterproof capability.

- Thickness range: 4mm–8mm

- Water resistance: Can withstand 24-hour water immersion without significant swelling or deformation

- Suitable environment: Kitchen, bathroom, basement, and other humid areas

Compared with traditional solid wood flooring, SPC flooring will not warp or mold in humid environments.

1.2 Wear and Scratch Resistance

SPC flooring usually has a wear-resistant layer (UV coating or reinforced layer), significantly enhancing scratch and wear resistance.

- Wear layer thickness: 0.3mm–0.7mm

- Wear resistance grade: AC3–AC5 (suitable for high-traffic areas in homes and commercial spaces)

- Scratch resistance test: Can withstand daily furniture friction and pet claws

1.3 Dimensional Stability and Deformation Resistance

Due to the low expansion coefficient of the stone-plastic composite material, SPC flooring maintains excellent dimensional stability under temperature and humidity changes.

- Thermal expansion coefficient: approx. 5 × 10⁻⁵ /℃

- High-temperature tolerance: Can withstand 60℃ for long-term use

- Shrinkage/expansion resistance: Remains flat under ±40% humidity changes

1.4 Comfort and Sound Insulation

Although SPC flooring is known for its hardness, with proper underlayer design and locking structure, it provides good foot comfort and certain sound insulation.

- Surface hardness: approx. 60–70 Shore D

- Walking noise reduction: 10–15 dB (compared with tiles)

- Thickness impact on comfort: 6–8mm thickness balances durability and comfort

In summary, SPC flooring offers waterproof, scratch-resistant, stable, and comfortable advantages, making it highly practical for residential, office, and commercial spaces.

2. SPC Flooring Installation Guide

SPC (Stone Plastic Composite) flooring is easy to install due to its stable structure, waterproof and wear-resistant properties. Correct installation is crucial for longevity and comfort.

2.1 Pre-Installation Preparation

1. Subfloor Treatment

- The subfloor should be flat, dry, solid, without cracks or protrusions

- Flatness standard: ≤ 2 mm / 2 m

- Moisture requirement: Cement-sand subfloor ≤ 2%, wooden subfloor ≤ 12%

2. Environmental Adaptation

- SPC flooring should be placed indoors for 48 hours before installation to adapt to temperature and humidity

- Room temperature: 18–28℃, humidity 40–60%

3. Tool Preparation

- Measuring tools: tape measure, level

- Cutting tools: flooring saw, cutter

- Installation aids: rubber mallet, wooden wedges, pull bar

2.2 Installation Method

SPC flooring mainly uses floating click-lock installation, without glue or nails.

Lock Types Comparison

| Type | Advantages | Applicable Scene |

|---|---|---|

| Single-direction lock | Fast installation, low cost | Small rooms |

| Multi-direction lock | Tighter joint, higher stability | Large or high-traffic areas |

| Press-fit lock | Better waterproof, easy disassembly | Bathrooms, kitchens |

Installation Steps Overview

- Reserve expansion gap: 5–10 mm between flooring and wall

- Align first row along the longest wall

- Lock the next plank into the previous one and tap to fix

- Cut and trim at corners or pipes

- Check completion: ensure tight locks and flat surface

2.3 Key Installation Parameters

| Parameter | Recommended Value | Description |

|---|---|---|

| Floor thickness | 4–8 mm | Thicker flooring improves stability and comfort |

| Drying time | ≥48 hours | Allows material to adapt to room conditions |

| Lock gap | ≤0.1 mm | Ensures seamless fit and minimizes movement |

| Expansion gap | 5–10 mm | Allows thermal expansion and contraction |

| Subfloor flatness | ≤2 mm / 2 m | Ensures flatness and prevents hollowing |

2.4 Notes

- Avoid wet installation

- Control temperature: avoid extreme environment installation

- Large rooms can be installed in zones

- Use furniture pads for heavy objects

- Light cleaning after installation

Sturdy & Moisture-Proof Easy Install Thickness 6.5mm SPC flooring YXSPC22965

3. SPC Flooring Cleaning and Maintenance

3.1 Daily Cleaning

- Tools: soft broom, vacuum cleaner, slightly damp mop

- Frequency: high-traffic areas daily, low-traffic areas 2–3 times/week

- Notes: avoid hard brushes or steel brushes, prevent water standing

3.2 Deep Cleaning

- Recommended cleaner: neutral pH (6–8)

- Method: wipe with slightly damp mop, then dry immediately

- Water temperature: ≤40℃

3.3 Regular Maintenance

| Maintenance | Frequency | Description |

|---|---|---|

| Apply protective wax | Every 6–12 months | Enhances wear resistance and maintains gloss |

| Check lock gaps | Every 6 months | Ensure no loosening or warping |

| Dust/debris removal | 1–2 times/week | Prevent scratches |

| Prevent heavy object impact | Ongoing | Use furniture pads to reduce dents |

3.4 Cleaning Comparison with Other Flooring

| Floor Type | Waterproof | Stain Resistance | Cleaning Difficulty | Durability |

|---|---|---|---|---|

| SPC Flooring | 100% | High | Low | High (AC3–AC5) |

| WPC Flooring | Partial | Medium | Medium | Medium (AC3–AC4) |

| Solid Wood | Low | Medium | High | Medium |

| Engineered Wood | Low–Medium | Medium | Medium | Medium |

3.5 Notes

- Avoid sharp objects scratching

- Avoid strong acids or bases

- Avoid high-temperature steam cleaning

- Regularly check locks and seams

4. Environmental Analysis of SPC Flooring

4.1 Material Composition and Environmental Features

| Material | Proportion | Environmental Feature |

|---|---|---|

| Stone powder (Calcium Carbonate) | 50%–70% | Non-toxic, non-radioactive, stable |

| PVC | 30%–50% | Waterproof, wear-resistant, plasticizer content controlled |

| Stabilizers and pigments | Small | Ensure uniform color and stability |

4.2 VOC Emission and Indoor Air Quality

High-quality SPC flooring has VOC emission ≤0.5 mg/m³, meeting international indoor air standards.

| Floor Type | VOC Emission | Indoor Air Impact |

|---|---|---|

| SPC Flooring | ≤0.5 mg/m³ | Low |

| WPC Flooring | 0.5–1 mg/m³ | Medium |

| Solid Wood | 0.3–0.8 mg/m³ | Low–Medium |

| Engineered Wood | 0.5–1 mg/m³ | Medium |

4.3 Recyclability and Lifespan

- Recyclability: Stone powder and PVC can be recycled professionally

- Lifespan: 15–20 years

- Disposal: Avoid burning, use industrial recycling or landfill

4.4 Environmental Comparison with Other Flooring

| Material | Recyclability | Lifespan | VOC Emission | Environmental Summary |

|---|---|---|---|---|

| SPC Flooring | Medium | 15–20 years | Low | High stone powder, durable, environmentally friendly |

| WPC Flooring | Medium | 10–15 years | Medium | More plasticizer |

| Solid Wood | High | 20–30 years | Low–Medium | Biodegradable but uses forest resources |

| Engineered Wood | Low–Medium | 10–15 years | Medium | Glue affects environmental performance |

4.5 Usage Suggestions

- Choose qualified products

- Check environmental certifications

- Proper installation and maintenance

- Recycle waste properly

5. Comparison Between SPC and WPC Flooring

5.1 Material Structure

| Floor Type | Main Material | Composition | Stability | Waterproof |

|---|---|---|---|---|

| SPC Flooring | Stone powder + PVC | High stone powder ratio | Very high | 100% |

| WPC Flooring | Wood powder + PVC | High wood powder ratio | High | Partial |

5.2 Wear and Scratch Resistance

| Floor Type | Wear Layer | AC Grade | Applicable Environment |

|---|---|---|---|

| SPC Flooring | UV coating or reinforced layer | AC3–AC5 | Home, high-traffic commercial |

| WPC Flooring | UV coating | AC3–AC4 | Home, low-traffic office |

5.3 Foot Comfort and Sound Insulation

| Floor Type | Hardness (Shore D) | Sound Reduction | Foot Comfort |

|---|---|---|---|

| SPC Flooring | 60–70 | 10–15 dB | Firm, stable |

| WPC Flooring | 35–55 | 12–18 dB | Softer, comfortable |

5.4 Installation Method Comparison

| Floor Type | Installation | Difficulty | Expansion Gap |

|---|---|---|---|

| SPC Flooring | Floating click-lock | Easy | 5–10 mm |

| WPC Flooring | Click-lock or glue | Medium | 5–12 mm |

5.5 Lifespan and Maintenance

| Floor Type | Lifespan | Daily Maintenance | Wet Area Usage |

|---|---|---|---|

| SPC Flooring | 15–20 years | Easy, low maintenance | Suitable for kitchen/bathroom |

| WPC Flooring | 10–15 years | Moderate maintenance | Needs waterproofing in wet areas |

5.6 Summary Recommendations

- High traffic or humid areas: SPC Flooring

- Bedrooms or children's rooms: WPC Flooring

- Budget and cost-effectiveness: SPC is better

- Environmental considerations: SPC with high stone powder, low VOC

6. Summary and Recommendations

6.1 Core Advantages Review

| Advantage | Performance |

|---|---|

| Waterproof | 100%, suitable for kitchen, bathroom, basement |

| Durability | Wear layer AC3–AC5, suitable for high traffic |

| Stability | High stone powder ratio, low thermal expansion, resists warping |

| Foot comfort & sound insulation | Moderate hardness, walking stability, reduces noise 10–15 dB |

| Environmental | VOC ≤0.5 mg/m³, long lifespan reduces environmental impact |

6.2 Usage and Installation Recommendations

- Check subfloor, use floating click-lock installation, reserve expansion gap

- Daily cleaning with soft broom or damp mop

- Regular maintenance with wax and lock inspection

- Use furniture pads for heavy objects

6.3 Recommended Usage Scenarios

- Humid areas: SPC Flooring

- High traffic spaces: SPC Flooring

- Bedrooms/children's rooms: thick SPC or add soft mat

- Environmental priority: low VOC SPC

6.4 Overall Recommendation

- Prioritize SPC Flooring

- Consider comfort and sound insulation based on space

- Proper installation and maintenance maximize lifespan and eco-benefits

7. FAQ

7.1 What is SPC Flooring? What is the difference between SPC and WPC Flooring?

SPC Flooring (Stone Plastic Composite Flooring) is a new flooring material composed of stone powder and PVC, featuring 100% waterproof, wear-resistant, and dimensionally stable properties. Compared with WPC Flooring (Wood Plastic Composite Flooring), SPC performs better in humid and high-traffic areas, while WPC offers slightly better comfort and sound insulation.

Company Information: Haining Yunxi New Material Technology Co., Ltd. have a long been focusing on the independent research and development and production of wood veneer wall panels and flooring and has a rich product system in the industry. Not only can fully meet the needs of various styles of home decoration but also meet the needs of various types of construction projects, loved and favored by consumers.

7.2 How to install and maintain SPC Flooring?

SPC Flooring usually adopts floating click-lock installation, requiring no glue. The subfloor should be flat (≤2 mm / 2 m) and dry before installation. For daily cleaning, use a soft broom or slightly damp mop, avoiding strong acids, bases, or hot water. Regular maintenance, such as applying neutral wax every 6–12 months and inspecting lock gaps, can extend the lifespan of SPC Flooring to 15–20 years.

Company Information: As an all-round development of modern enterprise, in recent years, Haining Yunxi New Material Technology Co., Ltd. in technological innovation, brand building, team management, and other aspects of the rapid pace of development has been attracting the attention of the industry.

7.3 How environmentally friendly is SPC Flooring? Is it suitable for home use?

High-quality SPC Flooring has VOC emission ≤0.5 mg/m³, meeting international indoor air standards. Its high stone powder content and long lifespan reduce environmental burden, making it highly suitable for homes, children's rooms, and commercial spaces, providing a safe and healthy flooring solution.

Company Information: Haining Yunxi New Material Technology Co., Ltd. have a long been focusing on the independent research and development and production of wood veneer wall panels and flooring and has a rich product system in the industry, fully meeting various home decoration and construction project requirements, loved and favored by consumers.